Specific Process Knowledge/Thermal Process/Oxidation: Difference between revisions

Appearance

| Line 27: | Line 27: | ||

|x||x||.||.||.||.||. | |x||x||.||.||.||.||. | ||

|- | |- | ||

!Wet oxidation with | !Wet oxidation with bubbler (water steam + N2) | ||

|.||.||x (with special permission)||x||x||x||. | |.||.||x (with special permission)||x||x||x||. | ||

|- | |- | ||

| Line 68: | Line 68: | ||

<nowiki>**</nowiki>These wafers must be placed in a "transport box from RCA to furnace" using the RCA carrier when doing RCA or the pre-dep carrier after pre-dep. | <nowiki>**</nowiki>These wafers must be placed in a "transport box from RCA to furnace" using the RCA carrier when doing RCA or the pre-dep carrier after pre-dep. | ||

==Oxidation curves== | ==Oxidation curves== | ||

Revision as of 14:59, 26 February 2008

Oxidation

At Danchip we have six furnaces for oxidation: A1,A3,C1,C2,C3 and D1. Oxidation can take place either by a dry process or a wet process. The film quality of dry oxide is better than for wet oxide with regards to density and dielectric constant. If the film quality for the wet oxide is acceptable then the thickness and the time it takes to grow the oxide often decides if a dry or wet oxidation is chosen.

- Dry oxide is used from 5nm - 200nm. Can be grown in furnaces:A1,A3,C1,C2,C3.

- Wet oxide with O2 and H2 can be grown in furnace:A1,A3.

- Wet oxide with H2O in a bobler can be grown in furnaces:C1,C2,C3.

Comparing the six oxidation furnaces

| ' | A1 Boron drive-in |

A3 Phosphorous drive-in |

C1 Gate oxide |

C2 Anneal oxide |

C3 Anneal bond |

D1 APOX |

Noble |

| General description | Drive-in of boron deposited in the boron pre-dep furnace(A2) or drive-in of ion implanted boron. Can also be used for dry and wet oxidation. | Drive-in of phosphorous deposited in the phosphorous pre-dep furnace(A2) or drive-in of ion implanted phosphorous. Can also be used for dry and wet oxidation. | Oxidation of gate-oxide and other especially clean oxides. At the moment also used for general oxidation of 6" wafers. | Oxidation and annealing of wafers from the B-stack and PECVD1. | Oxidation and annealing of wafers from NIL. | Oxidation of very thick oxides | Oxidation and annealing for all materials. |

|---|---|---|---|---|---|---|---|

| Dry oxidation | x | x | x (with special permission) | x | x | . | x (after request) |

| wet oxidation with torch (H2+O2) | x | x | . | . | . | . | . |

| Wet oxidation with bubbler (water steam + N2) | . | . | x (with special permission) | x | x | x | . |

| Process temperature [ oC ] | 800-1150 | 800-1150 | 800-1150 | 800-1150 | 800-1150 | 1150 | . |

| Cleanliness of dry oxide (rated 1-5, 1 is best) | 2 | 2 | 1 | 3 | 4 | . | >5 |

| Cleanliness of wet oxide (rated 1-4, 1 is best) | 1 | 1 | 2 | 3 | 4 | 3 | . |

| Batch size | max. 30 wafers of 4" or 2" | max. 30 4" wafers or 2" wafers | max. 30 wafers of 6",4" or 2" | max. 30 4" wafers or 2" wafers | max. 30 4" wafers or 2" wafers | max. 200 4" | ? |

| Which wafers are allowed to enter the furnace: | A1 Boron drive-in |

A3 Phosphorous drive-in |

C1 Gate oxide |

C2 Anneal oxide |

C3 Anneal bond |

D1 APOX |

Noble |

| New clean* Si wafers 4" (6" in C1) | x | x | x (with special permission) | x | x | x | x |

| RCA clean** Si wafers with no history of Metals on | x | x | x (with special permission) | x | x | . | x |

| From Predep furnace directly (e.g. incl. Predep HF**) | From A2 | From A4 | . | x | x | . | x |

| Wafers directly from PECVD1 | . | . | . | x | x | . | x |

| Wafers directly from NIL bonding | . | . | . | . | x | . | x |

| All materials must enter the furnace | . | . | . | . | . | . | x |

*New clean: only right from the new clean box. It is not allowed to put them in another box first.

**These wafers must be placed in a "transport box from RCA to furnace" using the RCA carrier when doing RCA or the pre-dep carrier after pre-dep.

Oxidation curves

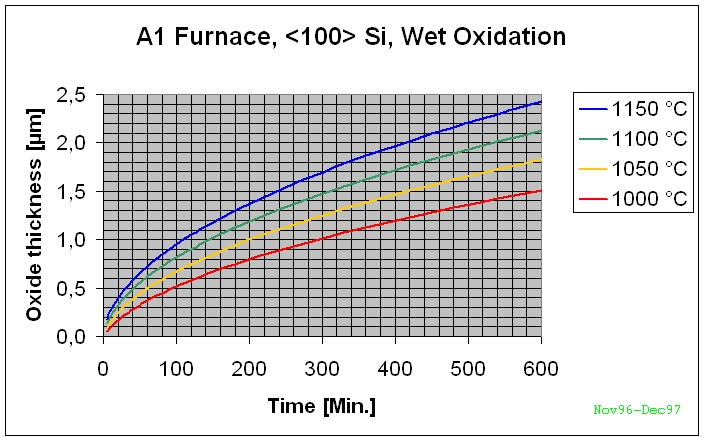

A1 Furnace <100>-Si Wet Oxidation

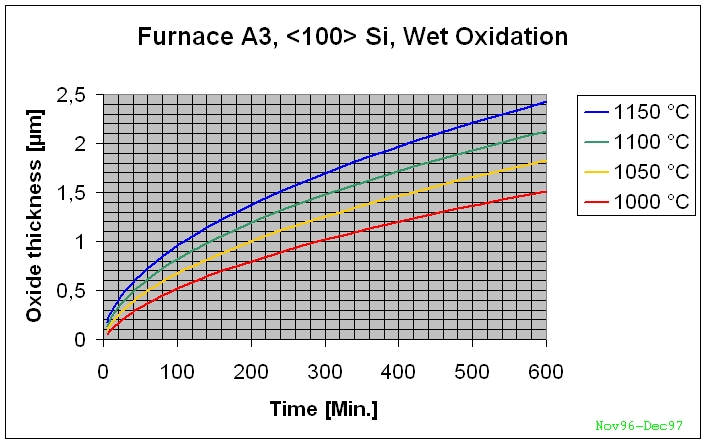

A3 Furnace <100>-Si Wet Oxidation

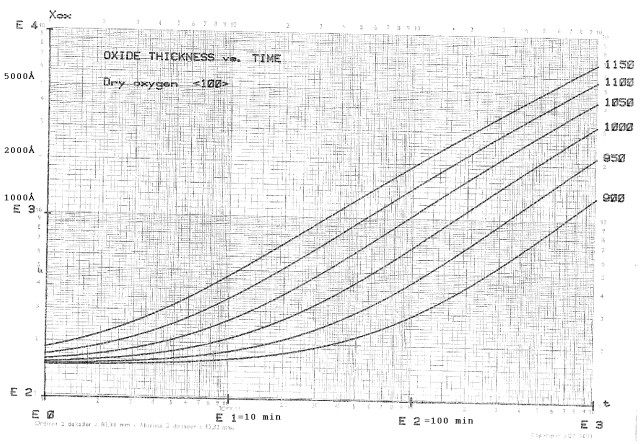

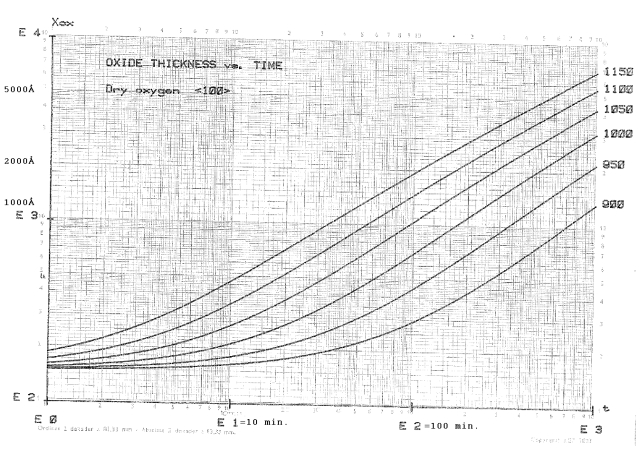

Furnace <100>-Si Dry Oxidation