Specific Process Knowledge/Back-end processing/Laser Micromachining Tool/fluence: Difference between revisions

Appearance

No edit summary |

|||

| Line 20: | Line 20: | ||

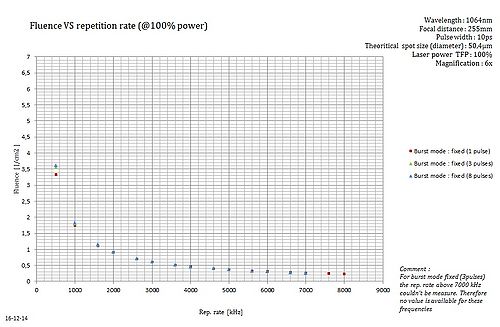

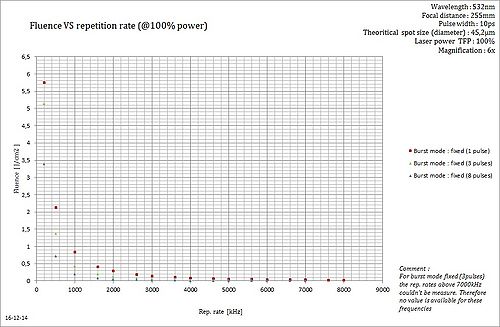

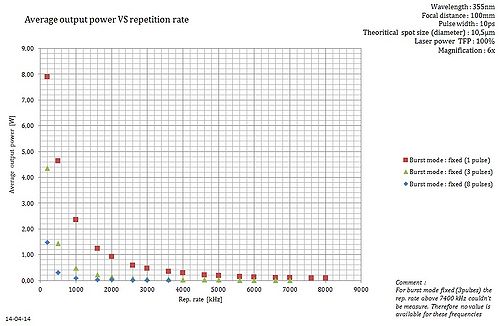

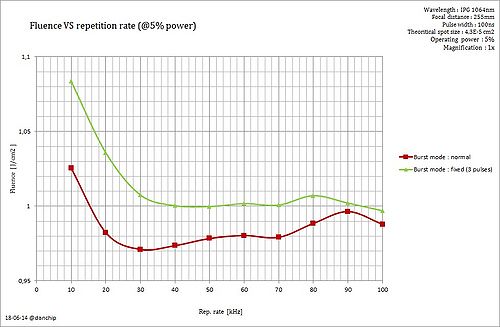

== Fluence results measurement== | == Fluence results measurement== | ||

The results below have been calculated with the theoretical spot size provided by 3D Micromac. | The results below have been calculated with the theoretical [[Specific Process Knowledge/Back-end processing/Laser Micromachining Tool/Spot size and optics|spot size]] provided by 3D Micromac. | ||

{| border="1" cellspacing="2" cellpadding="2" | {| border="1" cellspacing="2" cellpadding="2" | ||

Revision as of 14:44, 19 December 2014

Fluence definition

The fluence produces by a laser is, by definition, the energy delivered by a laser pulse () per surface unit () and it is given in J/cm2.

The function is defined as :

Where (average power) is measured with the laser sensor power measurement (see manual,section 5.3) and the repetion rate () is set in the parameter file under " laser frequency".

The fluence is therefore determinated as such :

The area () can be determinate with the theoretical min spot diameter (1/e2), available here

Fluence results measurement

The results below have been calculated with the theoretical spot size provided by 3D Micromac.

|

|

|

|---|

|

|---|