Specific Process Knowledge/Characterization/AFM: Atomic Force Microscopy: Difference between revisions

No edit summary |

|||

| Line 2: | Line 2: | ||

[[ | ==AFM Icon == | ||

[[Image:P6180008.JPG|right|thumb|300px| AFM Icon-Pt Positioned in clean room: F-2]] | |||

The AFM | The AFM Dimension Icon is a product of Bruker. AFM stands for Atomic Force Microscope which is a scanning probe microscope where a sharp probe is scanned across a surface either in contact mode, tapping mode or PeakForce tapping mode. The outcome is a topographic plot of the surface. It has a lateral solution of about 1 nm and a vertical resolution of less than 1 Å which makes it very suitable for topographic characterization in the nanometer regime. The limiting factor however is often the size of the probe in use. The tip radius of curvature (ROC) can be from 2 nm up to more than 20 nm depending on the chosen probe. The half cone angle of the tip can vary from less than 3<sup>o</sup> to over 25<sup>o</sup> giving problems resolving high aspect ratio structures. | ||

The main purposes are surface roughness measurements and step/structure high measurements in the nanometer and sub-micrometer regime. For larger structure see the [[Specific Process Knowledge/Characterization/Topographic measurement|topografic measurement]] page. | The main purposes are surface roughness measurements and step/structure high measurements in the nanometer and sub-micrometer regime. For larger structure see the [[Specific Process Knowledge/Characterization/Topographic measurement|topografic measurement]] page. | ||

To get some product information from the vendor take a look at Bruker's homepage [http://www.bruker-axs.com/atomicforcemicroscopy.html] | To get some product information from the vendor take a look at Bruker's homepage [http://www.bruker-axs.com/atomicforcemicroscopy.html] | ||

'''The user manual, quality control procedure and results and contact information can be found in LabManager:''' <br/> | '''The user manual, quality control procedure and results and contact information can be found in LabManager:''' <br/> | ||

[http://labmanager.danchip.dtu.dk/function.php?module=Machine&view=view&mach= | [http://labmanager.danchip.dtu.dk/function.php?module=Machine&view=view&mach=337 Nanoman in LabManager] | ||

==Process Information== | ==Process Information== | ||

<!-- | |||

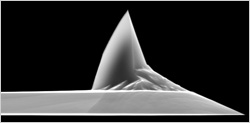

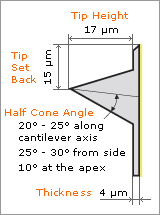

[[Image:Tap300Al-G.jpg|right|thumb|Std. tip Tap300Al-G]] | [[Image:Tap300Al-G.jpg|right|thumb|Std. tip Tap300Al-G]] | ||

[[Image:Tap300Al-G-schematic.png|right|thumb|Std. tip Tap300Al-G]] | [[Image:Tap300Al-G-schematic.png|right|thumb|Std. tip Tap300Al-G]] | ||

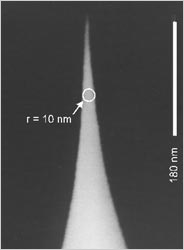

[[Image:SSS-NCHR-AFM-tip.jpg|right|thumb|SSS-NCHR tip<br /> (Super-Sharp-Silicon)]] | [[Image:SSS-NCHR-AFM-tip.jpg|right|thumb|SSS-NCHR tip<br /> (Super-Sharp-Silicon)]] | ||

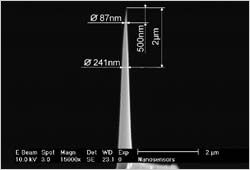

[[Image:Nanoman cantilever AR5.jpg|right|thumb|AR5-NCHR tip<br /> (Aspect Ratio 5)]] | [[Image:Nanoman cantilever AR5.jpg|right|thumb|AR5-NCHR tip<br /> (Aspect Ratio 5)]] | ||

--> | |||

*For a tutorial on AFM see here: [http://www.doitpoms.ac.uk/tlplib/afm/index.php AFM] | |||

*Free analysis software: For visualizing and analyzing AFM and Optical profiler files (Nanoman and Sensofar) [http://gwyddion.net Gwyddion] | |||

*or you can install Brukers own software analyses program that can be found on the cleanroom drive: U:\DCH\CleanroomDrive\_Equipment\AFM\NanoScope_Ananlysis_x64_v150b53.exe | |||

*[[/AFM Icon Acceptance|AFM Icon Acceptance]] | |||

*[[/Workspaces|What experiment and probe to select]] | |||

==An overview of the performance of the AFM | ==An overview of the performance of the AFM Icon== | ||

{| border="2" cellspacing="0" cellpadding="2" | {| border="2" cellspacing="0" cellpadding="2" | ||

!colspan="2" border="none" style="background:silver; color:black;" align="center"|Equipment | !colspan="2" border="none" style="background:silver; color:black;" align="center"|Equipment | ||

|style="background:WhiteSmoke; color:black"|<b> | |style="background:WhiteSmoke; color:black"|<b>AFM Icon</b> | ||

|- | |- | ||

!style="background:silver; color:black;" align="left"|Purpose | !style="background:silver; color:black;" align="left"|Purpose | ||

|style="background:LightGrey; color:black"|Topografic measurement in the nanometer and and sub-micrometer regime | |style="background:LightGrey; color:black"|Topografic measurement in the nanometer and and sub-micrometer regime and electrical and mechanical measurements | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

*Surface roughness measurement | *Surface roughness measurement | ||

*Step/structure hight measurement | *Step/structure hight measurement | ||

*Surface image | *Surface image | ||

*Surface potential | |||

*Modulus | |||

*Adhesion | |||

*Deformation | |||

|- | |- | ||

!style="background:silver; color:black" align="left"|Performance | !style="background:silver; color:black" align="left"|Performance | ||

| Line 48: | Line 55: | ||

|style="background:silver; color:black"| | |style="background:silver; color:black"| | ||

|style="background:LightGrey; color:black"|Scan range z | |style="background:LightGrey; color:black"|Scan range z | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| Up to 13µm | ||

|- | |||

|style="background:silver; color:black"| | |||

|style="background:LightGrey; color:black"|Vertical noise floor | |||

|style="background:WhiteSmoke; color:black"|<30pm RMS | |||

|- | |||

|style="background:silver; color:black"| | |||

|style="background:LightGrey; color:black"|X-Y position noise (closed loop) | |||

|style="background:WhiteSmoke; color:black"|<0.15nm RMS | |||

|- | |||

|style="background:silver; color:black"| | |||

|style="background:LightGrey; color:black"|Z sensor noise level(closed loop) | |||

|style="background:WhiteSmoke; color:black"|35pm RMS | |||

|- | |- | ||

|style="background:silver; color:black"| | |style="background:silver; color:black"| | ||

|style="background:LightGrey; color:black"| | |style="background:LightGrey; color:black"|Integral nonlinearity(X-Y-Z) | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"|<0.5% | ||

|- | |- | ||

|style="background:silver; color:black"| | |style="background:silver; color:black"| | ||

|style="background:LightGrey; color:black"| | |style="background:LightGrey; color:black"|X-Y position noise (closed loop) | ||

|style="background:WhiteSmoke; color:black"|< | |style="background:WhiteSmoke; color:black"|<0.15nm RMS | ||

|- | |- | ||

|style="background:silver; color:black"| | |style="background:silver; color:black"| | ||

| Line 67: | Line 87: | ||

|- | |- | ||

|style="background:silver; color:black"| | |style="background:silver; color:black"| | ||

|style="background:LightGrey; color:black"|Standard Cantilevers/tips | |style="background:LightGrey; color:black"|Standard SanAsyst mode Cantilever/tip | ||

|style="background:WhiteSmoke; color:black"|[http://www.brukerafmprobes.com/p-3726-scanasyst-air.aspx ScanAsyst in Air] | |||

|- | |||

|style="background:silver; color:black"| | |||

|style="background:LightGrey; color:black"|Standard Tapping mode Cantilevers/tips | |||

|style="background:WhiteSmoke; color:black"|[http://www.nanoandmore.com/AFM-Probe-Tap300Al-G.html Tap300Al-G] | |style="background:WhiteSmoke; color:black"|[http://www.nanoandmore.com/AFM-Probe-Tap300Al-G.html Tap300Al-G] | ||

|- | |- | ||

| Line 80: | Line 104: | ||

|style="background:silver; color:black"| | |style="background:silver; color:black"| | ||

|style="background:LightGrey; color:black"|Cantilevers/tips vendor | |style="background:LightGrey; color:black"|Cantilevers/tips vendor | ||

|style="background:WhiteSmoke; color:black"|[http://www.nanoandmore.com/home.php www.nanoandmore.com] | |style="background:WhiteSmoke; color:black"| | ||

*[http://www.brukerafmprobes.com Bruker] | |||

*[http://www.nanoandmore.com/home.php www.nanoandmore.com] | |||

|- | |- | ||

|- | |- | ||

!style="background:silver; color:black" align="left"|Substrates | !style="background:silver; color:black" align="left"|Substrates | ||

|style="background:LightGrey; color:black"|Substrate size | |style="background:LightGrey; color:black"|Substrate size | ||

|style="background:WhiteSmoke; color:black"|Up to | |style="background:WhiteSmoke; color:black"|Up to 210mm in diameter and up to 15mm thick" | ||

|- | |||

!style="background:silver; color:black" align="left"| | |||

|style="background:LightGrey; color:black"|Motorized stage (X-Y axis) | |||

|style="background:WhiteSmoke; color:black"| | |||

*180mmx150mm inspection area | |||

*2µm repeatability, unidirectional | |||

*3µm repeatability, bidirectional | |||

|- | |- | ||

|style="background:silver; color:black"| | |style="background:silver; color:black"| | ||

| Line 95: | Line 128: | ||

<br clear="all" /> | <br clear="all" /> | ||

== | ==Nanoman== | ||

[[ | |||

The AFM | [[image:Nanoman.jpg|290x290px|right|thumb|Nanoman: positioned in cleanroom F-2]] | ||

The AFM: Nanoman is a product of Bruker. AFM stands for Atomic Force Microscope which is a scanning probe microscope where a sharp probe is scanned across a surface either in contact mode or tapping mode. The outcome is a topographic plot of the surface. It has a lateral solution of about 1 nm and a vertical resolution of less than 1 Å which makes it very suitable for topographic characterization in the nanometer regime. The limiting factor however is often the size of the probe in use. The tip radius of curvature (ROC) can be from 2 nm up to more than 20 nm depending on the chosen probe. The half cone angle of the tip can vary from less than 3<sup>o</sup> to over 25<sup>o</sup> giving problems resolving high aspect ratio structures. | |||

The main purposes are surface roughness measurements and step/structure high measurements in the nanometer and sub-micrometer regime. For larger structure see the [[Specific Process Knowledge/Characterization/Topographic measurement|topografic measurement]] page. | The main purposes are surface roughness measurements and step/structure high measurements in the nanometer and sub-micrometer regime. For larger structure see the [[Specific Process Knowledge/Characterization/Topographic measurement|topografic measurement]] page. | ||

To get some product information from the vendor take a look at Bruker's homepage [http://www.bruker-axs.com/atomicforcemicroscopy.html] | To get some product information from the vendor take a look at Bruker's homepage [http://www.bruker-axs.com/atomicforcemicroscopy.html] (Bruker acquired Veeco's AFM business in Oct. 2010) | ||

'''The user manual, quality control procedure and results and contact information can be found in LabManager:''' <br/> | '''The user manual, quality control procedure and results and contact information can be found in LabManager:''' <br/> | ||

[http://labmanager.danchip.dtu.dk/function.php?module=Machine&view=view&mach= | [http://labmanager.danchip.dtu.dk/function.php?module=Machine&view=view&mach=125 Nanoman in LabManager] | ||

==Process Information== | ==Process Information== | ||

[[Image:Tap300Al-G.jpg|right|thumb|Std. tip Tap300Al-G]] | [[Image:Tap300Al-G.jpg|right|thumb|Std. tip Tap300Al-G]] | ||

[[Image:Tap300Al-G-schematic.png|right|thumb|Std. tip Tap300Al-G]] | [[Image:Tap300Al-G-schematic.png|right|thumb|Std. tip Tap300Al-G]] | ||

[[Image:SSS-NCHR-AFM-tip.jpg|right|thumb|SSS-NCHR tip<br /> (Super-Sharp-Silicon)]] | [[Image:SSS-NCHR-AFM-tip.jpg|right|thumb|SSS-NCHR tip<br /> (Super-Sharp-Silicon)]] | ||

[[Image:Nanoman cantilever AR5.jpg|right|thumb|AR5-NCHR tip<br /> (Aspect Ratio 5)]] | [[Image:Nanoman cantilever AR5.jpg|right|thumb|AR5-NCHR tip<br /> (Aspect Ratio 5)]] | ||

For a tutorial on AFM see here: [http://www.doitpoms.ac.uk/tlplib/afm/index.php AFM] | |||

Free analysis software: For visualizing and analyzing AFM and Optical profiler files (Nanoman and Sensofar) [http://gwyddion.net Gwyddion] <br> | |||

Or you can install Brukers own software analyses program that can be found here on the cleanroom drive: U:\DCH\CleanroomDrive\_Equipment\AFM\NanoScope_Ananlysis_x64_v150b53.exe | |||

==An overview of the performance of the AFM: Nanoman== | |||

==An overview of the performance of the AFM | |||

{| border="2" cellspacing="0" cellpadding="2" | {| border="2" cellspacing="0" cellpadding="2" | ||

!colspan="2" border="none" style="background:silver; color:black;" align="center"|Equipment | !colspan="2" border="none" style="background:silver; color:black;" align="center"|Equipment | ||

|style="background:WhiteSmoke; color:black"|<b> | |style="background:WhiteSmoke; color:black"|<b>Nanoman</b> | ||

|- | |- | ||

!style="background:silver; color:black;" align="left"|Purpose | !style="background:silver; color:black;" align="left"|Purpose | ||

|style="background:LightGrey; color:black"|Topografic measurement in the nanometer and and sub-micrometer regime | |style="background:LightGrey; color:black"|Topografic measurement in the nanometer and and sub-micrometer regime | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

*Surface roughness measurement | *Surface roughness measurement | ||

*Step/structure hight measurement | *Step/structure hight measurement | ||

*Surface image | *Surface image | ||

|- | |- | ||

!style="background:silver; color:black" align="left"|Performance | !style="background:silver; color:black" align="left"|Performance | ||

| Line 147: | Line 174: | ||

|style="background:silver; color:black"| | |style="background:silver; color:black"| | ||

|style="background:LightGrey; color:black"|Scan range z | |style="background:LightGrey; color:black"|Scan range z | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| 1 µm (can go up to 6µm with special settings) | ||

|- | |- | ||

|style="background:silver; color:black"| | |style="background:silver; color:black"| | ||

|style="background:LightGrey; color:black"| | |style="background:LightGrey; color:black"|Resolution xy | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"|Down to 1.4 nm - accuracy better than 2% | ||

|- | |- | ||

|style="background:silver; color:black"| | |style="background:silver; color:black"| | ||

|style="background:LightGrey; color:black"| | |style="background:LightGrey; color:black"|Resolution z | ||

|style="background:WhiteSmoke; color:black"|< | |style="background:WhiteSmoke; color:black"|<1 Å - accuracy better than 2% | ||

|- | |- | ||

|style="background:silver; color:black"| | |style="background:silver; color:black"| | ||

| Line 179: | Line 193: | ||

|- | |- | ||

|style="background:silver; color:black"| | |style="background:silver; color:black"| | ||

|style="background:LightGrey; color:black"|Standard | |style="background:LightGrey; color:black"|Standard Cantilevers/tips | ||

|style="background:WhiteSmoke; color:black"|[http://www.nanoandmore.com/AFM-Probe-Tap300Al-G.html Tap300Al-G] | |style="background:WhiteSmoke; color:black"|[http://www.nanoandmore.com/AFM-Probe-Tap300Al-G.html Tap300Al-G] | ||

|- | |- | ||

| Line 196: | Line 206: | ||

|style="background:silver; color:black"| | |style="background:silver; color:black"| | ||

|style="background:LightGrey; color:black"|Cantilevers/tips vendor | |style="background:LightGrey; color:black"|Cantilevers/tips vendor | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"|[http://www.nanoandmore.com/home.php www.nanoandmore.com] | ||

|- | |- | ||

|- | |- | ||

!style="background:silver; color:black" align="left"|Substrates | !style="background:silver; color:black" align="left"|Substrates | ||

|style="background:LightGrey; color:black"|Substrate size | |style="background:LightGrey; color:black"|Substrate size | ||

|style="background:WhiteSmoke; color:black"|Up to | |style="background:WhiteSmoke; color:black"|Up to 6" | ||

|- | |- | ||

|style="background:silver; color:black"| | |style="background:silver; color:black"| | ||

Revision as of 09:19, 24 October 2014

Feedback to this page: click here

AFM Icon

The AFM Dimension Icon is a product of Bruker. AFM stands for Atomic Force Microscope which is a scanning probe microscope where a sharp probe is scanned across a surface either in contact mode, tapping mode or PeakForce tapping mode. The outcome is a topographic plot of the surface. It has a lateral solution of about 1 nm and a vertical resolution of less than 1 Å which makes it very suitable for topographic characterization in the nanometer regime. The limiting factor however is often the size of the probe in use. The tip radius of curvature (ROC) can be from 2 nm up to more than 20 nm depending on the chosen probe. The half cone angle of the tip can vary from less than 3o to over 25o giving problems resolving high aspect ratio structures.

The main purposes are surface roughness measurements and step/structure high measurements in the nanometer and sub-micrometer regime. For larger structure see the topografic measurement page.

To get some product information from the vendor take a look at Bruker's homepage [1]

The user manual, quality control procedure and results and contact information can be found in LabManager:

Nanoman in LabManager

Process Information

- For a tutorial on AFM see here: AFM

- Free analysis software: For visualizing and analyzing AFM and Optical profiler files (Nanoman and Sensofar) Gwyddion

- or you can install Brukers own software analyses program that can be found on the cleanroom drive: U:\DCH\CleanroomDrive\_Equipment\AFM\NanoScope_Ananlysis_x64_v150b53.exe

An overview of the performance of the AFM Icon

| Equipment | AFM Icon | |

|---|---|---|

| Purpose | Topografic measurement in the nanometer and and sub-micrometer regime and electrical and mechanical measurements |

|

| Performance | Scan range xy | Up to 90 µm square |

| Scan range z | Up to 13µm | |

| Vertical noise floor | <30pm RMS | |

| X-Y position noise (closed loop) | <0.15nm RMS | |

| Z sensor noise level(closed loop) | 35pm RMS | |

| Integral nonlinearity(X-Y-Z) | <0.5% | |

| X-Y position noise (closed loop) | <0.15nm RMS | |

| Max. scan depth as a function of trench width W | ~1 for our standard probe. Can be improved to about 10 with the right probe | |

| Hardware settings | Tip radius of curvature | Standard probe: <12 nm |

| Standard SanAsyst mode Cantilever/tip | ScanAsyst in Air | |

| Standard Tapping mode Cantilevers/tips | Tap300Al-G | |

| Super Sharp Si Cantilever/tip | SSS-NCHR | |

| High Aspect Ratio Cantilever/tip | AR5-NCHR | |

| Cantilevers/tips vendor | ||

| Substrates | Substrate size | Up to 210mm in diameter and up to 15mm thick" |

| Motorized stage (X-Y axis) |

| |

| Substrate material allowed | In principle all materials | |

Nanoman

The AFM: Nanoman is a product of Bruker. AFM stands for Atomic Force Microscope which is a scanning probe microscope where a sharp probe is scanned across a surface either in contact mode or tapping mode. The outcome is a topographic plot of the surface. It has a lateral solution of about 1 nm and a vertical resolution of less than 1 Å which makes it very suitable for topographic characterization in the nanometer regime. The limiting factor however is often the size of the probe in use. The tip radius of curvature (ROC) can be from 2 nm up to more than 20 nm depending on the chosen probe. The half cone angle of the tip can vary from less than 3o to over 25o giving problems resolving high aspect ratio structures.

The main purposes are surface roughness measurements and step/structure high measurements in the nanometer and sub-micrometer regime. For larger structure see the topografic measurement page.

To get some product information from the vendor take a look at Bruker's homepage [2] (Bruker acquired Veeco's AFM business in Oct. 2010)

The user manual, quality control procedure and results and contact information can be found in LabManager:

Nanoman in LabManager

Process Information

(Super-Sharp-Silicon)

(Aspect Ratio 5)

For a tutorial on AFM see here: AFM

Free analysis software: For visualizing and analyzing AFM and Optical profiler files (Nanoman and Sensofar) Gwyddion

Or you can install Brukers own software analyses program that can be found here on the cleanroom drive: U:\DCH\CleanroomDrive\_Equipment\AFM\NanoScope_Ananlysis_x64_v150b53.exe

An overview of the performance of the AFM: Nanoman

| Equipment | Nanoman | |

|---|---|---|

| Purpose | Topografic measurement in the nanometer and and sub-micrometer regime |

|

| Performance | Scan range xy | Up to 90 µm square |

| Scan range z | 1 µm (can go up to 6µm with special settings) | |

| Resolution xy | Down to 1.4 nm - accuracy better than 2% | |

| Resolution z | <1 Å - accuracy better than 2% | |

| Max. scan depth as a function of trench width W | ~1 for our standard probe. Can be improved to about 10 with the right probe | |

| Hardware settings | Tip radius of curvature | Standard probe: <12 nm |

| Standard Cantilevers/tips | Tap300Al-G | |

| Super Sharp Si Cantilever/tip | SSS-NCHR | |

| High Aspect Ratio Cantilever/tip | AR5-NCHR | |

| Cantilevers/tips vendor | www.nanoandmore.com | |

| Substrates | Substrate size | Up to 6" |

| Substrate material allowed | In principle all materials | |