Specific Process Knowledge/Lithography/mrEBL6000: Difference between revisions

Appearance

No edit summary |

|||

| Line 33: | Line 33: | ||

== Process Flow == | == Process Flow == | ||

Test of | Test of mr EBL 6000.1; a negative e-beam resist from MicroResist. | ||

{|border="1" cellspacing="0" cellpadding="3" style="text-align:left;" style="width: 60%;" | {|border="1" cellspacing="0" cellpadding="3" style="text-align:left;" style="width: 60%;" | ||

| Line 54: | Line 54: | ||

|-style="background:LightGrey; color:black" | |-style="background:LightGrey; color:black" | ||

|4" Si wafers | |4" Si wafers | ||

| | |1 min @ 110 degC, hotplate | ||

| | | | ||

|- | |- | ||

| Line 67: | Line 67: | ||

|-style="background:LightGrey; color:black" | |-style="background:LightGrey; color:black" | ||

|Spin Coater Manual, LabSpin, A-5 | |Spin Coater Manual, LabSpin, A-5 | ||

| | |mr EBL 6000.1 E-beam resist | ||

60 sec at various spin speed. | 60 sec at various spin speed. | ||

Acceleration | Acceleration 2000 s-2, | ||

softbake | softbake 3 min at 110 deg Celcius | ||

|Disposal pipette used; clean by N2-gun before use. Use approximately 1.5 ml per 4" wafer, never use a pipette twice | |Disposal pipette used; clean by N2-gun before use. Use approximately 1.5 ml per 4" wafer, never use a pipette twice. | ||

|- | |- | ||

| Line 108: | Line 108: | ||

|-style="background:LightGrey; color:black" | |-style="background:LightGrey; color:black" | ||

|Fumehood, D-3 | |Fumehood, D-3 | ||

|60 sec in | |60 sec in | ||

60 sec rinse in IPA, | 60 sec rinse in IPA, | ||

N2 Blow dry | N2 Blow dry | ||

| Line 127: | Line 127: | ||

|} | |} | ||

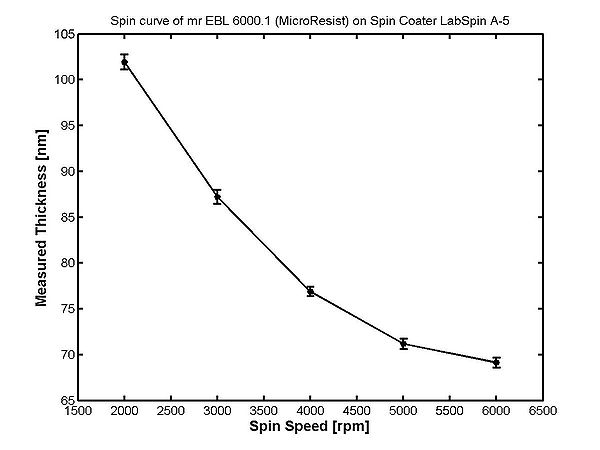

== Spin Curve == | == Spin Curve == | ||

Revision as of 12:49, 14 July 2014

| Resist | Polarity | Manufacturer | Comments | Technical reports | Spinner | Developer | Rinse | Remover | Process flows (in docx-format) |

| mr EBL 6000 | Positive | MicroResist | Standard negative resist | mrEBL6000 processing Guidelines.pdf | Manual Spinner 1 (Laurell), Spin Coater Labspin | mr DEV | IPA | Process_Flow_mrEBL6000.docx |

Process Flow

Test of mr EBL 6000.1; a negative e-beam resist from MicroResist.

| Equipment | Process Parameters | Comments | |

|---|---|---|---|

| Pretreatment | |||

| 4" Si wafers | 1 min @ 110 degC, hotplate | ||

| Spin Coat | |||

| Spin Coater Manual, LabSpin, A-5 | mr EBL 6000.1 E-beam resist

60 sec at various spin speed. Acceleration 2000 s-2, softbake 3 min at 110 deg Celcius |

Disposal pipette used; clean by N2-gun before use. Use approximately 1.5 ml per 4" wafer, never use a pipette twice. | |

| Characterization | |||

| Ellipsometer VASE B-1 | 9 points measured on 100 mm wafer | ZEP program used; measured at 70 deg only | |

| E-beam Exposure | |||

| JEOL 9500 E-beam writer, E-1 | Dosepattern 15nm - 100nm,

dose 120-280 muC/cm2 |

Virtual chip mark height detection (CHIPAL V1) used in corner of every dose array | |

| Development | |||

| Fumehood, D-3 | 60 sec in

60 sec rinse in IPA, N2 Blow dry |

Gentle agitation while developing. After developing, wafer is immersed in beaker with IPA, subsequently blow dried with N2 gun. | |

| Characterization | |||

| Zeiss SEM Supra 60VP, D-3 | 2-3 kV, shortest working distance possible, chip mounted with Al tape | The wafers are diced into smaller pieces and sputter coated with Pt at DTU CEN before SEM inspection; please contact Ramona Valentina Mateiu for further information. | |

Spin Curve

The thickness is measured on VASE Ellipsometer using a simple Cauchy model for a transparent polymer on Si. The measurements are performed at one incidence angle (70 degrees) only. 9 points on each 4" wafer has been measured; the standard deviation thus representing the homogeinity of the film on the 4" wafers.

| MicroResist mr EBL 6000 spinning on Spin Coater: Manual LabSpin A-5, TIGRE, 14-07-2014. Softbake 3 min @ 110 degC. | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [1/s2] | Thickness [nm] | St Dev | |||

| 2000 | 2000 | |||||

| 3000 | 2000 | |||||

| 4000 | 2000 | |||||

| 5000 | 2000 | |||||

| 6000 | 2000 | |||||