Specific Process Knowledge/Etch/III-V ICP/InP-InGaAsP-InGaAs: Difference between revisions

Appearance

Created page with "'''Feedback to this page''': '''[mailto:labadviser@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php/Specific_Process_Knowledge/Etc..." |

No edit summary |

||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:labadviser@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php/Specific_Process_Knowledge/Etch/III-V_ICP/InP-InGaAsP-InGaAs click here]''' | '''Feedback to this page''': '''[mailto:labadviser@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php/Specific_Process_Knowledge/Etch/III-V_ICP/InP-InGaAsP-InGaAs click here]''' | ||

=== InP/InGaAsP/InGaAs etch === | === InP/InGaAsP/InGaAs etch === | ||

Revision as of 10:41, 1 August 2016

Feedback to this page: click here

InP/InGaAsP/InGaAs etch

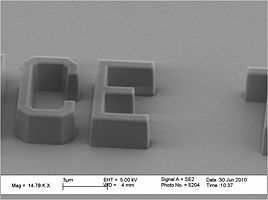

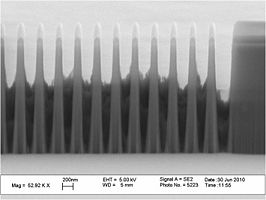

Unselective etch for large sized features and small aspect ratios by David Larsson, DTU Photonics, 2011

| Recipe | InP Etch 1/InP Precond 1 |

| Cl2 flow | 20 sccm |

| N2 flow | 40 sccm |

| Ar flow | 10 sccm |

| Platen power | 100 W |

| Coil power | 500 W |

| Pressure | 2 mTorr |

| Platen chiller temperature | 180 oC |

| Results (InP Etch 1) | |

| Etch rate | 500-600 nm/min |

| Sidewall angle | 86-87 o |

| Selectivity (InP:SiO2, InP:HSQ) | 50:1 |

- Result of InP etching. David Larsson, DTU Photonics, 2011