Specific Process Knowledge/Back-end processing/Polishing machine: Difference between revisions

Appearance

| Line 20: | Line 20: | ||

!colspan="2" border="none" style="background:silver; color:black;" align="center"|Equipment | !colspan="2" border="none" style="background:silver; color:black;" align="center"|Equipment | ||

|style="background:WhiteSmoke; color:black"|<b>Polisher/Lapper</b> | |style="background:WhiteSmoke; color:black"|<b>Polisher/Lapper</b> | ||

|style="background:WhiteSmoke; color:black"|<b>Equipment 2</b> | <!-- |style="background:WhiteSmoke; color:black"|<b>Equipment 2</b> --> | ||

|- | |- | ||

!style="background:silver; color:black;" align="center" width="60"|Purpose | !style="background:silver; color:black;" align="center" width="60"|Purpose | ||

| Line 31: | Line 31: | ||

*Metals | *Metals | ||

*Glass/Quartz | *Glass/Quartz | ||

|style="background:WhiteSmoke; color:black"| | <!-- |style="background:WhiteSmoke; color:black"| | ||

*Purpose 1 | *Purpose 1 | ||

*Purpose 2 | *Purpose 2 | ||

*Purpose 3 | *Purpose 3 --> | ||

|- | |- | ||

!style="background:silver; color:black" align="center" valign="center" rowspan="2"|Performance | !style="background:silver; color:black" align="center" valign="center" rowspan="2"|Performance | ||

| Line 43: | Line 43: | ||

*Thickness homogeneity: +/- 10 µm | *Thickness homogeneity: +/- 10 µm | ||

*Roughness: +/- ? µm | *Roughness: +/- ? µm | ||

|style="background:WhiteSmoke; color:black"| | <!-- |style="background:WhiteSmoke; color:black"| | ||

*Performance range 1 | *Performance range 1 | ||

*Performance range 2 | *Performance range 2 | ||

*Performance range 3 | *Performance range 3 --> | ||

|- | |- | ||

|style="background:LightGrey; color:black"|Polishing | |style="background:LightGrey; color:black"|Polishing | ||

| Line 54: | Line 54: | ||

*Thickness homogeneity: ? µm | *Thickness homogeneity: ? µm | ||

*Roughness: +/- ? µm | *Roughness: +/- ? µm | ||

|style="background:WhiteSmoke; color:black"| | <!-- |style="background:WhiteSmoke; color:black"| | ||

*Performance range | *Performance range --> | ||

|- | |- | ||

!style="background:silver; color:black" align="center" valign="center" rowspan="3"|Process parameter range | !style="background:silver; color:black" align="center" valign="center" rowspan="3"|Process parameter range | ||

| Line 62: | Line 62: | ||

*Al2O3 (alumina) powder: 3, 9 or 20 µm | *Al2O3 (alumina) powder: 3, 9 or 20 µm | ||

*Chemlox (for polishing) | *Chemlox (for polishing) | ||

|- | |- | ||

|style="background:LightGrey; color:black"|Rotation speed | |style="background:LightGrey; color:black"|Rotation speed | ||

| Line 69: | Line 67: | ||

*Thinning: 5-20 rpm | *Thinning: 5-20 rpm | ||

*Polishing: 5-80 rpm | *Polishing: 5-80 rpm | ||

|- | |- | ||

|style="background:LightGrey; color:black"|Arm sweep | |style="background:LightGrey; color:black"|Arm sweep | ||

| Line 76: | Line 72: | ||

*Thinning: stationary | *Thinning: stationary | ||

*Polishing: 12% (inner) - 80% (outer) | *Polishing: 12% (inner) - 80% (outer) | ||

|- | |- | ||

!style="background:silver; color:black" align="center" valign="center" rowspan="3"|Substrates | !style="background:silver; color:black" align="center" valign="center" rowspan="3"|Substrates | ||

| Line 85: | Line 79: | ||

*<nowiki>#</nowiki> 50 mm wafers | *<nowiki>#</nowiki> 50 mm wafers | ||

*<nowiki>#</nowiki> 100 mm wafers | *<nowiki>#</nowiki> 100 mm wafers | ||

|style="background:WhiteSmoke; color:black"| | <!-- |style="background:WhiteSmoke; color:black"| | ||

*<nowiki>#</nowiki> small samples | *<nowiki>#</nowiki> small samples | ||

*<nowiki>#</nowiki> 50 mm wafers | *<nowiki>#</nowiki> 50 mm wafers | ||

*<nowiki>#</nowiki> 100 mm wafers | *<nowiki>#</nowiki> 100 mm wafers | ||

*<nowiki>#</nowiki> 150 mm wafers | *<nowiki>#</nowiki> 150 mm wafers --> | ||

|- | |- | ||

| style="background:LightGrey; color:black"|Allowed materials | | style="background:LightGrey; color:black"|Allowed materials | ||

| Line 98: | Line 92: | ||

*Metals | *Metals | ||

*Glass/Quartz | *Glass/Quartz | ||

|style="background:WhiteSmoke; color:black"| | <!-- |style="background:WhiteSmoke; color:black"| | ||

*Allowed material 1 | *Allowed material 1 | ||

*Allowed material 2 | *Allowed material 2 | ||

*Allowed material 3 | *Allowed material 3 --> | ||

|- | |- | ||

|} | |} | ||

<br clear="all" /> | <br clear="all" /> | ||

Revision as of 13:46, 3 February 2014

Feedback to this page: click here

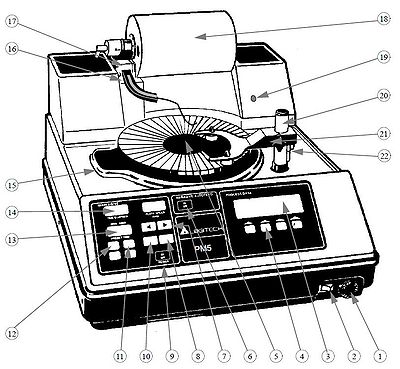

Polisher/Lapper

The Logitech PM5 Polisher/Lapper is for thinning down wafers and other substrates.

The user manual, user APV(s), technical information and contact information can be found in LabManager:

The Logitech PM5 Polisher/Lapper in LabManager

| Equipment | Polisher/Lapper | |

|---|---|---|

| Purpose |

Thinning of substrates of |

|

| Performance | Thinning |

|

| Polishing |

| |

| Process parameter range | Polishing liquid |

|

| Rotation speed |

| |

| Arm sweep |

| |

| Substrates | Batch size |

|

| Allowed materials |

| |