Specific Process Knowledge/Thermal Process/Oxidation: Difference between revisions

| Line 8: | Line 8: | ||

*Wet oxide with H<sub>2</sub>O in a bubbler can be grown in furnaces: C1, C3, D1, nobel. | *Wet oxide with H<sub>2</sub>O in a bubbler can be grown in furnaces: C1, C3, D1, nobel. | ||

[[/A1 Bor Drive-in furnace|Boron Drive-in + Predep furnace (A1)]] | == Choose an equipment to use == | ||

*[[/A1 Bor Drive-in furnace|Boron Drive-in + Predep furnace (A1)]] - ''For oxidation and annealing of Si wafesr, and for boron pre-deposition (doping) and for drive-in afterwards'' | |||

*[[/C2 Gate Oxide furnace|Gate Oxide furnace (A2)]] - ''For gate oxide growing on new wafers'' | |||

*[[/A3 Phosphor Drive-in furnace|Phosphorus Drive-in furnace (A3)]] - ''For oxidation and annealing of Si wafers and for drive-in after phosphorus pre-dep'' | |||

*[[/A4 Phosphor Pre-dep furnace|Phosphorus Predep furnace (A4)]] - ''For pre-deposition (doping) of phosphorus on Si wafers'' | |||

*[[/C1 Furnace Anneal-oxide|Anneal-oxide furnace(C1)]] - ''For oxidation and annealing of 100 mm and 150 mm wafers'' | |||

*[[/C3 Anneal-bond furnace|Anneal-bond furnace (C3)]] - ''For oxidation and annealing of bonded wafers'' | |||

*[[/C4 Aluminium Anneal furnace|Aluminium Anneal furnace (C4)]] - ''For oxidation and annealing of wafers containing aluminium'' | |||

*[[/Furnace Noble|Noble furnace]] - ''For annealing and oxidation of non-clean wafers'' | |||

*[[/Furnace APOX|APOX furnace]] - ''For growing of very thick oxide layers'' | |||

*[[/Jipelec RTP|Jipelec RTP]] - ''For rapid thermal annealing of III-V materials and Si based materials'' | |||

*[[/BCB Curing Oven|BCB Curing oven]] - ''For resist curing and metal alloying'' | |||

*[[/Resist Pyrolysis Furnace|Resist Pyrolysis furnace]] - ''For pyrolysis of different resist layers'' | |||

==Comparison of the six oxidation furnaces== | ==Comparison of the six oxidation furnaces== | ||

Revision as of 11:07, 12 December 2013

Feedback to this page: click here

Oxidation

At Danchip we have seven furnaces for oxidation: A1, A2, A3, C1, C3, D1 and nobel. Oxidation can take place either by a dry process or a wet process. The film quality of dry oxide is better than for wet oxide with regards to density and dielectric constant. If the film quality for the wet oxide is acceptable then the thickness and the time it takes to grow the oxide often decides if a dry or wet oxidation is chosen.

- Dry oxide is used from 5 nm - 200 nm. Can be grown in furnaces: A1, A2, A3, C1, C3.

- Wet oxide with O2 and H2 can be grown in furnace: A1, A3.

- Wet oxide with H2O in a bubbler can be grown in furnaces: C1, C3, D1, nobel.

Choose an equipment to use

- Boron Drive-in + Predep furnace (A1) - For oxidation and annealing of Si wafesr, and for boron pre-deposition (doping) and for drive-in afterwards

- Gate Oxide furnace (A2) - For gate oxide growing on new wafers

- Phosphorus Drive-in furnace (A3) - For oxidation and annealing of Si wafers and for drive-in after phosphorus pre-dep

- Phosphorus Predep furnace (A4) - For pre-deposition (doping) of phosphorus on Si wafers

- Anneal-oxide furnace(C1) - For oxidation and annealing of 100 mm and 150 mm wafers

- Anneal-bond furnace (C3) - For oxidation and annealing of bonded wafers

- Aluminium Anneal furnace (C4) - For oxidation and annealing of wafers containing aluminium

- Noble furnace - For annealing and oxidation of non-clean wafers

- APOX furnace - For growing of very thick oxide layers

- Jipelec RTP - For rapid thermal annealing of III-V materials and Si based materials

- BCB Curing oven - For resist curing and metal alloying

- Resist Pyrolysis furnace - For pyrolysis of different resist layers

Comparison of the six oxidation furnaces

| ' | A1 Boron drive-in |

A3 Phosphorous drive-in |

C1 Anneal oxide |

A2 Gate oxide |

C3 Anneal bond |

D1 APOX |

Noble |

| General description | Drive-in of boron deposited in the boron pre-dep furnace(A2) or drive-in of ion implanted boron. Can also be used for dry and wet oxidation. | Drive-in of phosphorous deposited in the phosphorous pre-dep furnace(A2) or drive-in of ion implanted phosphorous. Can also be used for dry and wet oxidation. | Oxidation and annealing of wafers from the B-stack and PECVD1. At the moment also used for general oxidation of 6" wafers. | Oxidation of gate-oxide and other especially clean oxides. | Oxidation and annealing of wafers from NIL. | Oxidation of very thick oxides | Oxidation and annealing for all materials. |

|---|---|---|---|---|---|---|---|

| Dry oxidation | x | x | x | x(with special permission) | x | . | x (after request) |

| wet oxidation with torch (H2+O2) | x | x | . | . | . | . | . |

| Wet oxidation with bubbler (water steam + N2) | . | . | x | . | x | x | . |

| Process temperature [ oC ] | 800-1150 | 800-1150 | 800-1150 | 800-1150 | 800-1150 | 1150 | . |

| Cleanliness of dry oxide (rated 1-5, 1 is best) | 2 | 2 | 3 | 1 | 4 | . | >5 |

| Cleanliness of wet oxide (rated 1-4, 1 is best) | 1 | 1 | 2 | . | 4 | 3 | . |

| Batch size | max. 30 wafers of 4" or 2" | max. 30 4" wafers or 2" wafers | max. 30 wafers of 6",4" or 2" | max. 30 4" wafers or 2" wafers | max. 30 4" wafers or 2" wafers | max. 200 4" | max. 30 wafers |

| Which wafers are allowed to enter the furnace: | A1 Boron drive-in |

A3 Phosphorous drive-in |

C1 Anneal oxide |

A2 Gate oxide |

C3 Anneal bond |

D1 APOX |

Noble |

| RCA clean* Si wafers with no history of Metals on | x | x | x | x (with special permission) | x | . | x |

| From Predep furnace directly (e.g. incl. Predep HF*) | From A1 | From A4 | x | . | x | . | x |

| Wafers directly from PECVD2 | . | . | x | . | x | . | x |

| Wafers directly from NIL bonding | . | . | . | . | x | . | x |

| All materials must enter the furnace | . | . | . | . | . | . | x |

*These wafers must be placed in a "transport box from RCA to furnace" using the RCA carrier when doing RCA or the pre-dep carrier after pre-dep.

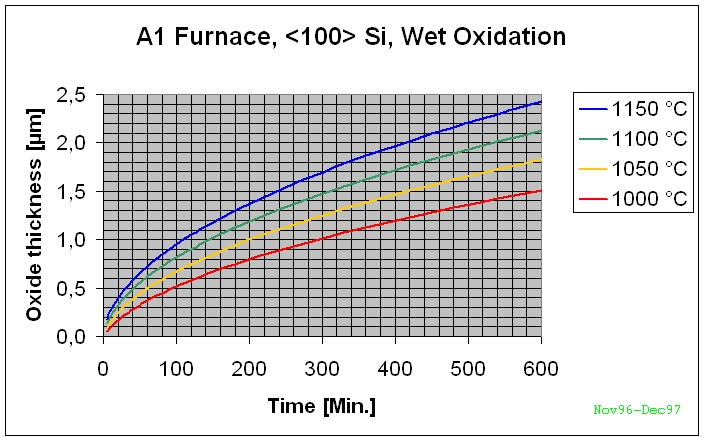

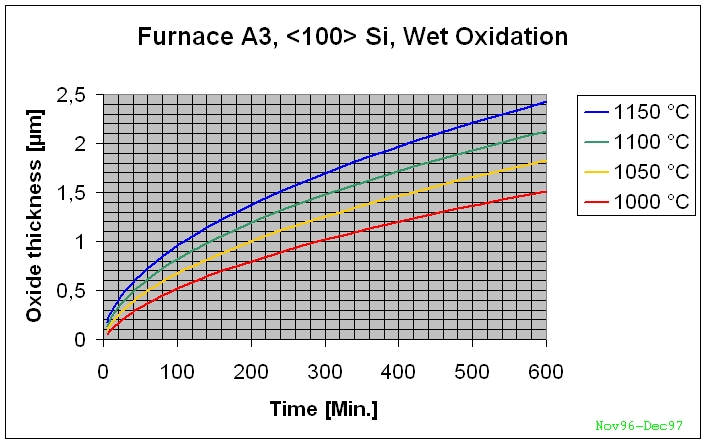

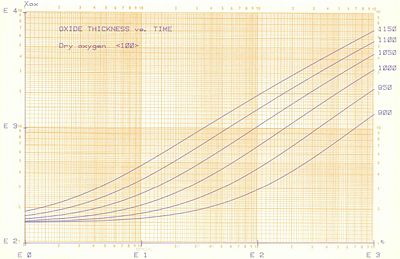

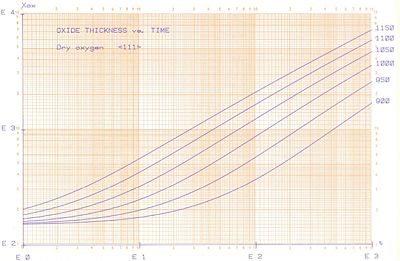

Oxidation curves

Generic calculator for wet/dry oxide thickness calculation

The following links give an approximate oxide time/thickness based on a general formula.

The curves below are based on measurements in our specific furnaces and give more accurate results.

A1 Furnace <100>-Si Wet Oxidation

A3 Furnace <100>-Si Wet Oxidation

Dry Oxidation on <100> and <111> wafer

- Dry oxidation

-

Dry oxide on <100> wafer

-

Dry oxide on <111> wafer