Specific Process Knowledge/Etch/IBE⁄IBSD Ionfab 300/IBE Au etch: Difference between revisions

Appearance

| Line 119: | Line 119: | ||

==IBE Au etch with Ti mask [[Image:section under construction.jpg|70px]] == | ==IBE Au etch with Ti mask [[Image:section under construction.jpg|70px]] == | ||

''by bge@danchip.dtu.dk'' | |||

Work has been started to find a good process for etching gold with a Titanium mask with high selektivity. | Work has been started to find a good process for etching gold with a Titanium mask with high selektivity. | ||

| Line 135: | Line 136: | ||

|-style="background:WhiteSmoke; color:black" | |-style="background:WhiteSmoke; color:black" | ||

!Generel description | !Generel description | ||

| | |This recipe has a good selectivity between ZEP520A resist and Ti, which makes it good for pattering the Ti that should be used as masking layer for the Au etch. It can also be used to for Au etch if the selektivity to the mask is good enough | ||

| | |This recipe has especially good selectivity between Ti and Au which makes it good for gold etching using a thin Ti mask as masking layer. The selectivity to resist is very bad so do not use it with a resist mask. | ||

|- | |- | ||

Revision as of 06:31, 29 August 2013

Results from the acceptance test in February 2011

Acceptance test for Au etch:

| . | Acceptance Criteria |

Acceptance Results |

|---|---|---|

| Substrate information |

|

. |

| Material to be etched |

|

. |

| Mask information |

|

. |

| Features to be etched |

|

. |

| Etch depth |

|

|

| Etch rate |

|

|

| Etch rate uniformity |

|

|

| Reproducibility |

|

|

| Selectivity (Au etch rate/ZEP etch rate) |

|

|

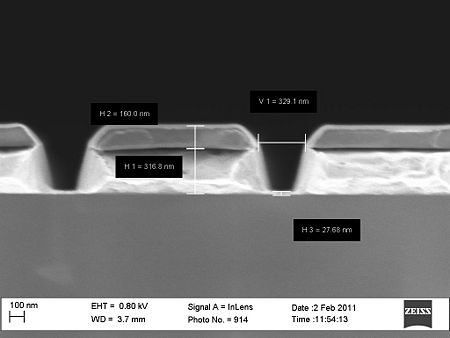

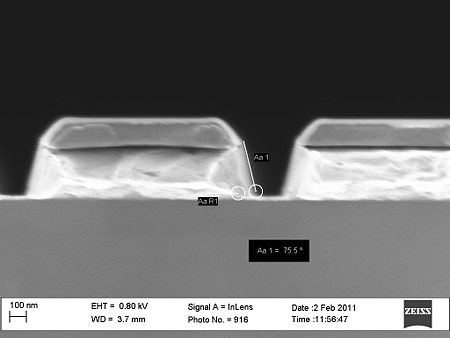

| Etch profile |

|

|

Process parameters for the acceptance test

| Parameter | Au etch acceptance |

|---|---|

| Neutalizer current [mA] | 550 |

| RF Power [W] | 1300 |

| Beam current [mA] | 500 |

| Beam voltage [V] | 600 |

| Beam accelerator voltage | 400 |

| Ar flow to neutralizer [sccm] | 5.0 |

| Ar flow to beam [sccm] | 10.0 |

| Rotation speed [rpm] | 20 |

| Stage angle [degrees] | 30 |

Some SEM profile images of the etched Au

|

|

|---|

IBE Au etch with Ti mask

by bge@danchip.dtu.dk

Work has been started to find a good process for etching gold with a Titanium mask with high selektivity.

| Ti etch test with Zep520A as mask - To etch the Ti mask | Au etch test with high selectivity to Ti | |

|---|---|---|

| Generel description | This recipe has a good selectivity between ZEP520A resist and Ti, which makes it good for pattering the Ti that should be used as masking layer for the Au etch. It can also be used to for Au etch if the selektivity to the mask is good enough | This recipe has especially good selectivity between Ti and Au which makes it good for gold etching using a thin Ti mask as masking layer. The selectivity to resist is very bad so do not use it with a resist mask. |

| Recipe name |

test Ti acceptance 20111129 |

Au_acceptance_with_O2 |

| IBE parameters |

|

|

| Results | ||

| Etch rate in resist |

12.8nm/min (15-12-2011) |

72nm/min (13-12-2011) |

| Etch rate in Au |

32.7nm/min (15-12-2011) |

42.6nm/min (13-12-2011) |

| Etch rate in Ti |

8.3nm/min (15-12-2011) |

4.3nm/min (13-12-2011) |

| Selectivity Ti/Zep |

0.65 (15-12-2011) |

0.06 (13-12-2011) |

| Selectivity Au/Ti |

3.9nm/min (15-12-2011) |

9.9nm/min (13-12-2011) |