Specific Process Knowledge/Lithography/Coaters: Difference between revisions

| Line 112: | Line 112: | ||

'''The user manual(s), quality control procedure(s) and results, user APV(s), technical information and contact information can be found in [http://labmanager.danchip.dtu.dk/function.php?module=Machine&view=view&mach=313 LabManager]''' | '''The user manual(s), quality control procedure(s) and results, user APV(s), technical information and contact information can be found in [http://labmanager.danchip.dtu.dk/function.php?module=Machine&view=view&mach=313 LabManager]''' | ||

<!-- remember to remove the type of documents that are not present --> | <!-- remember to remove the type of documents that are not present --> | ||

===Process information=== | |||

Link to process pages - e.g. one page for each material | |||

Example: | |||

*[[Specific Process Knowledge/Etch/Etching of Silicon/Si etch using RIE1 or RIE2|Etch of silicon using RIE]] | |||

*[[Specific Process Knowledge/Etch/Etching of Silicon Oxide/SiO2 etch using RIE1 or RIE2|Etch of silicon oxide using RIE]] | |||

*[[Specific Process Knowledge/Etch/Etching of Silicon Nitride/Etch of Silicon Nitride using RIE|Etch of silicon nitride using RIE]] | |||

*[[Specific Process Knowledge/Etch/Etching of Polymer/Etch of Photo Resist using RIE|Etch of photo resist using RIE]] | |||

=== Equipment performance and process related parameters === | === Equipment performance and process related parameters === | ||

| Line 191: | Line 202: | ||

<br clear="all" /> | <br clear="all" /> | ||

==KS Spinner== | ==KS Spinner== | ||

Revision as of 12:22, 19 June 2013

Coaters: Comparison Table

| Equipment | SSE Spinner | KS Spinner | |

|---|---|---|---|

| Purpose |

|

| |

| Performance | Substrate handling |

|

|

| Permanent media |

|

| |

| Manual dispense option |

|

| |

| Process parameter range | Parameter 1 |

|

|

| Parameter 2 |

|

| |

| Substrates | Batch size |

|

|

| Allowed materials |

|

| |

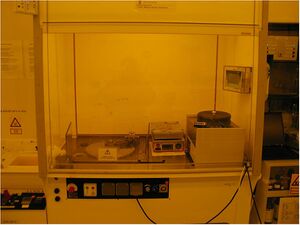

SSE Spinner

Feedback to this page: click here

The SSE spinner MAXIMUS: positioned in Cleanroom 13. SSE Spinner, Maximus 804, SSE Sister Semiconductor Equipment is a resist spinning system at Danchip which can be used for spinning on 2", 4" and 6" substrates.

The system is equipped with 2 different resists lines:

- AZ5214E and

- AZ4562 and

- 2 syringe lines, which can be used for spinning of e-beam resist.

The user manual(s), quality control procedure(s) and results and contact information can be found in LabManager: Equipment info in LabManager

A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here.

Spin Track 1 + 2

Feedback to this page: click here

Spin Track 1 + 2 is an SVG 88 series track system from Rite Track. Each track consists of a HMDS priming module, a spin coating module, and a baking module. In fact, the only difference between the two tracks is the resist used in the spin coating module. Spin Track 1 + 2 is capable of handling 150 mm wafers, as well as 100 mm wafers, but is currently set up for 100 mm wafer processing.

The Spin Track 1 + 2 is controlled using the Recipe Manager software via the touchscreen on the arm attached to the lefthand end of the track. Recipes for the individual modules are developed by Danchip and combined into flows. The user selects a flow (specific to track 1 or 2), and the appropriate recipes will be downloaded and executed on the appropriate track. The other track runs an empty process (no wafers needed), and can unfortunately not be used by a second user while the first user is processing.

The user manual(s), quality control procedure(s) and results, user APV(s), technical information and contact information can be found in LabManager

Process information

Link to process pages - e.g. one page for each material

Example:

- Etch of silicon using RIE

- Etch of silicon oxide using RIE

- Etch of silicon nitride using RIE

- Etch of photo resist using RIE

| Spin Track | 1 | 2 | |

|---|---|---|---|

| Purpose |

|

| |

| Resist |

AZ MiR 701 (29cps) positive tone |

AZ nLOF 2020 negative tone | |

| Performance | Coating thickness |

1 - 3 µm |

1.6 - 5 µm |

| HMDS contact angle |

60 - 90° (on SiO2) | ||

| Process parameters | Spin speed |

10 - 9990 rpm | |

| Spin acceleration |

1000 - 50000 rpm/s | ||

| Hotplate temperature |

90°C |

110°C | |

| HMDS priming temperature |

50°C | ||

| Substrates | Substrate size |

100 mm wafers | |

| Allowed materials |

Silicon (with oxide, nitride, or metal films or patterning) Glass (borosilicate and quartz) | ||

| Batch |

1 - 25 | ||

KS Spinner

A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here.

A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here.

A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here.

Manual Spinner 1 (Laurell)

A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here.

A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here. A lot of text here.