Specific Process Knowledge/Characterization/Profiler/Optical Profiler (Sensofar) acceptance test: Difference between revisions

No edit summary |

|||

| (21 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Characterization/Profiler/Optical_Profiler_(Sensofar)_acceptance_test click here]''' | |||

=<span style="color:#FF0000"> This optical profiler has been decommissioned and replaced by the S Neox system, which is very similar </span> = | |||

=Results from the Optical Profiler (Sensofar) acceptance test= | =Results from the Optical Profiler (Sensofar) acceptance test= | ||

The acceptance test was performed in January 2012 by ST Instruments and Sensofar together with | The acceptance test was performed in January 2012 by ST Instruments and Sensofar together with | ||

Pernille V. Larsen @ | Pernille V. Larsen@ DTU nanolab and Berit G. Herstrøm @ DTU nanolab. | ||

==This Table shows an overview of the acceptance tests== | ==This Table shows an overview of the acceptance tests== | ||

| Line 69: | Line 73: | ||

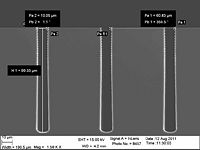

Measurement: Trench depth with aspect ratio 1:10, 1:11 and 1:13 on a 10µm, 8mm and 6.4µm wide trenches respectively | Measurement: Trench depth with aspect ratio 1:10, 1:11 and 1:13 on a 10µm, 8mm and 6.4µm wide trenches respectively | ||

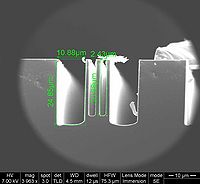

Acceptance criteria:Depth 100±2 µm, 91±2µm and 85±2µm. The SEM profile images of the three trenches are shown here: | Acceptance criteria: Depth 100±2 µm, 91±2µm and 85±2µm. The SEM profile images of the three trenches are shown here: | ||

{| border="1" cellspacing="1" cellpadding="2" | {| border="1" cellspacing="1" cellpadding="2" | ||

! | ! | ||

[[image:Sensofar_A1_SEM.jpg| | [[image:Sensofar_A1_SEM.jpg|200x200px|thumb|center|A1]] | ||

! | ! | ||

[[image:Sensofar_A2_SEM.jpg| | [[image:Sensofar_A2_SEM.jpg|200x200px|thumb|center|A2]] | ||

! | ! | ||

[[image:Sensofar_A3_SEM.jpg| | [[image:Sensofar_A3_SEM.jpg|200x200px|thumb|center|A3]] | ||

|} | |} | ||

| Line 94: | Line 98: | ||

==== | ====Settings for methode no. 1 for test no. 1, 2 and 3: confocal==== | ||

Recipe: Trench | Recipe: Trench | ||

*Operation mode: trench | *Operation mode: trench | ||

| Line 103: | Line 107: | ||

**Dual - bottom up | **Dual - bottom up | ||

***top: 8µm | ***top: 8µm | ||

***Gap: 91µm (the trench depth) | ***Gap: 91µm (<- choose the trench depth) | ||

***Bottom: 8µm | ***Bottom: 8µm | ||

**Speed factor: 1x | **Speed factor: 1x | ||

| Line 117: | Line 121: | ||

*Objective: Interferometric 50x DI | *Objective: Interferometric 50x DI | ||

*Z scan: VSI | *Z scan: VSI | ||

*Light | *Light source: increased gain and contrast | ||

==Results of acceptance test no. 4== | ==Results of acceptance test no. 4== | ||

Sample material: Patterned | Sample material: Patterned flat sample of glass | ||

Measurement: Depth of pattern | Measurement: Depth of pattern | ||

Standard profiler measurement: | Standard profiler measurement:335 nm | ||

Acceptance criteria:Depth within ±1% from a standard profiler measurement (331.65nm-338.35nm) and repeatability (3 successive measurements) within 0.1% | Acceptance criteria:Depth within ±1% from a standard profiler measurement (331.65nm-338.35nm) and repeatability (3 successive measurements) within 0.1% | ||

| Line 137: | Line 141: | ||

Treshold: 1% | Treshold: 1% | ||

Average 4 images (to reduce noise) | |||

| Line 150: | Line 156: | ||

| align="center" style="background:#f0f0f0;"|'''''' | | align="center" style="background:#f0f0f0;"|'''''' | ||

| align="center" style="background:#f0f0f0;"|'''Measured depth [nm]''' | | align="center" style="background:#f0f0f0;"|'''Measured depth [nm]''' | ||

| align="center" style="background:#f0f0f0;"|'''Repeated 20170925 with cover off''' | |||

| align="center" style="background:#f0f0f0;"|'''Repeated 20180816 after repair''' | |||

|- | |- | ||

| 1||337.5 | | 1||337.5||347.9||341.1 | ||

|- | |- | ||

| 2||336.5 | | 2||336.5||333.9||340.4 | ||

|- | |- | ||

| 3||334.7 | | 3||334.7||341.5||337.2 | ||

|- | |- | ||

| 4||335.5 | | 4||335.5||343.2||330.8 | ||

|- | |- | ||

| 5||339.2 | | 5||339.2||347.7||339.0 | ||

|- | |- | ||

| 6||337.2 | | 6||337.2||345.4||340.0 | ||

|- | |- | ||

| 7||334.2 | | 7||334.2||341.8||338.8 | ||

|- | |- | ||

| 8||335.5 | | 8||335.5||337.9||339.8 | ||

|- | |- | ||

| 9||341.1 | | 9||341.1||342.1||334.6 | ||

|- | |- | ||

| 10||344.4 | | 10||344.4||335.9||336.4 | ||

|- | |- | ||

|Average depth|| | |Average depth||337.58||341.73||337.82 | ||

|- | |- | ||

|Repeatability||3% (the bad repeatability was accepted due to the high noise level in the room) | |Repeatability||3.0% (the bad repeatability was accepted due to the high noise level in the room)||4.1%||3.0% | ||

|} | |} | ||

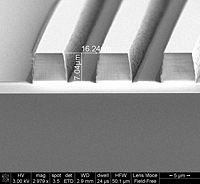

==Results of acceptance test no. 5== | ==Results of acceptance test no. 5== | ||

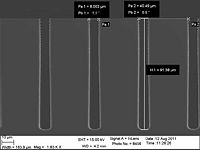

Sample: Flat sample of silicon with thick patterned oxide. | Sample: Flat sample of silicon with thick patterned oxide (APOX). | ||

Measurement: Step height of patterned thick (10 µm) oxide on top of a silicon wafer.The pattern is aprox. 7µm thick | Measurement: Step height of patterned thick (10 µm) oxide on top of a silicon wafer. The pattern is aprox. 7µm thick. | ||

Acceptance criteria: Step height must be within ±3% of a SEM profile measurement. See the SEM profile here: | Acceptance criteria: Step height must be within ±3% of a SEM profile measurement. See the SEM profile here: | ||

| Line 185: | Line 193: | ||

{| border="1" cellspacing="1" cellpadding="2" | {| border="1" cellspacing="1" cellpadding="2" | ||

! | ! | ||

[[Image:Sensofar_A5_SEM.jpg| | [[Image:Sensofar_A5_SEM.jpg|200x200px|thumb|center|A5]] | ||

|} | |} | ||

| Line 241: | Line 249: | ||

'''Settings:''' | '''Settings:''' | ||

Two different setting were tried out, the second was the most | Two different setting were tried out, the second was the most successful: | ||

Setting no. 1: | Setting no. 1: | ||

| Line 293: | Line 301: | ||

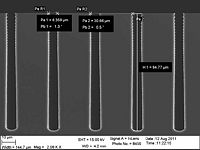

{| border="1" cellspacing="1" cellpadding="2" | {| border="1" cellspacing="1" cellpadding="2" | ||

! | ! | ||

[[image:Sensofar_A9_SEM.jpg| | [[image:Sensofar_A9_SEM.jpg|200x200px|thumb|center|SEM profile image of structure]] | ||

|} | |} | ||

| Line 327: | Line 335: | ||

Measurement:Film thickness measurement of transparent thin film | Measurement:Film thickness measurement of transparent thin film | ||

Acceptance criteria:SiO2 thickness 28±1 nm | Acceptance criteria: SiO2 thickness 28±1 nm | ||

| Line 342: | Line 350: | ||

==Results of acceptance test no. 11== | ==Results of acceptance test no. 11== | ||

Sample:120 nm nitride on 110 nm oxide on a silicon substrate | Sample: 120 nm nitride on 110 nm oxide on a silicon substrate | ||

Measurement:Measurements of multiple stacks | Measurement: Measurements of multiple stacks | ||

Acceptance criteria: Within ±2% on each layer from an ellipsometer measurement (SiO2: 112nm, Si3N4: 139nm) | Acceptance criteria: Within ±2% on each layer from an ellipsometer measurement (SiO2: 112nm, Si3N4: 139nm) | ||

| Line 361: | Line 369: | ||

Sample: Si with 1.4 µm patterned AZ-resist on 50µm pillars | Sample: Si with 1.4 µm patterned AZ-resist on 50µm pillars | ||

Measurement:Film thickness measurements of transparent films on small structure | Measurement: Film thickness measurements of transparent films on small structure | ||

Acceptance criteria:Within ±1% from a standard profiler measurement. | Acceptance criteria: Within ±1% from a standard profiler measurement. | ||

| Line 384: | Line 392: | ||

Acceptance criteria: Repeatability within 0.2% | Acceptance criteria: Repeatability within 0.2% | ||

Note: Because the surface roughness of the sample was very low and the noise/vibration level too high we could not obtain the specified | Note: Because the surface roughness of the sample was very low and the noise/vibration level too high we could not obtain the specified repeatability. | ||

| Line 390: | Line 398: | ||

'''Result''' | '''Result''' | ||

*The surface roughness (Ra) was 0.5nm | *The surface roughness (Ra) was 0.5nm | ||

*The | *The repeatability over 10 measurements was 34% | ||

*The maximum deviation in roughness was 0.2nm | *The maximum deviation in roughness was 0.2nm | ||

Latest revision as of 09:27, 4 September 2025

Feedback to this page: click here

This optical profiler has been decommissioned and replaced by the S Neox system, which is very similar

Results from the Optical Profiler (Sensofar) acceptance test

The acceptance test was performed in January 2012 by ST Instruments and Sensofar together with Pernille V. Larsen@ DTU nanolab and Berit G. Herstrøm @ DTU nanolab.

This Table shows an overview of the acceptance tests

| ' | Title | Sample description / measurement | Acceptance criteria |

| 1 | Patterned flat sample of silicon | Sample material: Patterned silicon substrate Trench depth with aspect ratio 1:10 on a 10 µm wide trench |

Depth 100±2 µm |

| 2 | Patterned flat sample of silicon. | Sample material: Patterned silicon substrate Trench depth with aspect ratio 1:11 on a 8 µm wide trench |

Depth 91±2 µm |

| 3 | Patterned flat sample of silicon | Sample material: Patterned silicon substrate Trench depth with aspect ratio 1:13 on a 6.4 µm wide trench |

Depth 85±2 µm |

| 4 | Patterned flat sample of glass | 3D profile of pattern etched down in a quartz sample. Pattern size 20 µm x 20 µm, depth 500 nm |

Depth within ±1% from a standard profiler measurement and repeatability (3 successive measurements) within 0.1% |

| 5 | Flat sample of silicon with thick patterned oxide | Step height of patterned thick (10 µm) oxide on top of a silicon wafer. 7 µm deep pattern, trench width 6 µm |

Step height must be within ±3% of a SEM profile measurement. |

| 6 | Flat sample of silicon with thick layer of patterned polymer | Sample material: SU8 on silicon. Pillar heights of 69 µm with 25 µm between pillar edges |

Height 69±2 µm |

| 7 | Free standing structure | Measure bow due to stress of a membrane. Membrane material: Si(2 µm)/SiO2(~1 µm)/Au(50 nm) Membrane size: honey comb structure approximately 150 µm in diameter Bow < 500 nm |

Membrane bow repeatability of 5 successive measurement within 2% |

| 8 | Stitching of large area | Stitching 4 mm x 4 mm on same sample as in 7. The area consists of many closed packed honey comb formed membranes. | Membrane bow must the same as on 7 within 2% |

| 9 | Narrow trenches and holes | Sample material: Patterned silicon substrate 2.5 µm wide trench in silicon with a depth of 20 µm |

Depth 20±2 µm |

| 10 | Film thickness measurement of transparent thin film | Transparent thin film thickness of 28 nm SiO2 on Si | SiO2 thickness 28±1 nm |

| 11 | Measurements of multiple stacks | 120 nm nitride on 110 nm oxide on a silicon substrate | Within ±2% on each layer from an ellipsometer measurement. |

| 12 | Film thickness measurements of transparent films on small structure | Sample material: Si with 1.5 µm patterned AZ-resist Measure thickness of AZ-resist on pillars of 50 µm in diameter |

Within ±1% from a standard profiler measurement. |

| 13 | Roughness repeatability | Sample material: Si wafer with poly-silicon layer 3 successive measurements of the roughness |

Repeatability within 0.2% |

Results of acceptance test no. 1, 2 and 3

Sample material: Patterned silicon substrate

Measurement: Trench depth with aspect ratio 1:10, 1:11 and 1:13 on a 10µm, 8mm and 6.4µm wide trenches respectively

Acceptance criteria: Depth 100±2 µm, 91±2µm and 85±2µm. The SEM profile images of the three trenches are shown here:

|

|

|

|---|

Results

Test no. 1 was done in two ways:

- With confocal objective EPI 100x-N: See the results here

- With Interferometric objective 50X DI: See the results here

Test no. 2 was done using: confocal objective EPI 100x-N: See the results here

Test no. 3 was done using: confocal objective EPI 100x-N: See the results here

Settings for methode no. 1 for test no. 1, 2 and 3: confocal

Recipe: Trench

- Operation mode: trench

- + Raw smoothing confocal

- + fine shift

- Objective: EPI 100X-N

- Z scan

- Dual - bottom up

- top: 8µm

- Gap: 91µm (<- choose the trench depth)

- Bottom: 8µm

- Speed factor: 1x

- + Linear stage

- Dual - bottom up

- Threshold: 0.0%

- Light source

- Levels: 2

- 900 -> 60 (might need to be set a little different)

- Gain: default

- Levels: 2

Setting for methode no. 2 for test no. 1: interferometric

We do not have a recipe for that but we used:

- Objective: Interferometric 50x DI

- Z scan: VSI

- Light source: increased gain and contrast

Results of acceptance test no. 4

Sample material: Patterned flat sample of glass

Measurement: Depth of pattern

Standard profiler measurement:335 nm

Acceptance criteria:Depth within ±1% from a standard profiler measurement (331.65nm-338.35nm) and repeatability (3 successive measurements) within 0.1%

System settings:

Objective: DI 50x-N

VSI z scan: 10µm

Treshold: 1%

Average 4 images (to reduce noise)

Results

It was repeated 10 Time.

The first measurement is shown here

This table show the depth value for the 10 measurements

| ' | Measured depth [nm] | Repeated 20170925 with cover off | Repeated 20180816 after repair |

| 1 | 337.5 | 347.9 | 341.1 |

| 2 | 336.5 | 333.9 | 340.4 |

| 3 | 334.7 | 341.5 | 337.2 |

| 4 | 335.5 | 343.2 | 330.8 |

| 5 | 339.2 | 347.7 | 339.0 |

| 6 | 337.2 | 345.4 | 340.0 |

| 7 | 334.2 | 341.8 | 338.8 |

| 8 | 335.5 | 337.9 | 339.8 |

| 9 | 341.1 | 342.1 | 334.6 |

| 10 | 344.4 | 335.9 | 336.4 |

| Average depth | 337.58 | 341.73 | 337.82 |

| Repeatability | 3.0% (the bad repeatability was accepted due to the high noise level in the room) | 4.1% | 3.0% |

Results of acceptance test no. 5

Sample: Flat sample of silicon with thick patterned oxide (APOX).

Measurement: Step height of patterned thick (10 µm) oxide on top of a silicon wafer. The pattern is aprox. 7µm thick.

Acceptance criteria: Step height must be within ±3% of a SEM profile measurement. See the SEM profile here:

|

|---|

Settings:

- Recipe: Acceptance nr. 5 SMR

- Mode: default

- Objective: 50x-DI

- VSI Z scan 18.0µm

- Threshold 2%

- Note: Scan only in the APOX (not in the Si) or else the system will get confused.

See the result here:

Results of acceptance test no. 6

Sample: Flat sample of silicon with thick layer of patterned SU8.

Measure: step height.

Acceptance criteria: Height 69±2 µm

Settings:

- Recipe: Acceptance nr. 6 SMR

- Mode: application Acceptance 6

- Raw smoothing confocal

- Coarse shift single samle

- Reject multiple reflections

- Objective: Confocal EPI 20x-N

- Z scan range: 104µm

- Threshold: 2.0%

See the result here:

Results of acceptance test no. 7

Sample: Free standing structure. Membrane material: Si(2 µm)/SiO2(~1 µm)/Au(50 nm). Membrane size: honey comb structure approximately 150 µm in diameter

Measure: Measure bow due to stress of a membrane.

Acceptance criteria: Membrane bow repeatability of 5 successive measurement within 2%

The sample was not as we suspected. There was almost no bow. The membrane looked broken and it did not really make any sense to measure the bow.

Settings: Two different setting were tried out, the second was the most successful:

Setting no. 1:

- Objective: DI 50x-N

- PSI

- Threshold 2%

Setting no. 2:

- Objective: DI 50x-N

- Z scan: VSI 10µm

- Threshold: 1.0%

Result

The measurement we did are shown here:

Results of acceptance test no. 8

Measurement: Stitching 4 mm x 4 mm on same sample as in 7.

Sample: The area consists of many closed packed honey comb formed membranes

Acceptance criteria: Membrane bow must the same as on 7 within 2%

Settings:

- Extended topography

- Objective: DI 20x-N

- Z scan: VSI: 40µm

- Threshold: 1.0%

Result:

We made a stitched image of the hole membrane and repeated it two times. It looked much the same but as for test 7 it was hard to do any measurements on it. See the images and profiles in the result file:

Results of acceptance test no. 9

Sample: Patterned silicon substrate.

Measurement: Narrow trench depth

Acceptance criteria: 20±2µm, see the SEM images here:

|

|---|

Setting

Recipe: Narrow trench

- Operation mode: narrow trench

- Coarse shift single sampling

- Objective: EPI 100X-N

- Z scan:

- Dual - bottom up

- top: 4µm

- Gap: 20µm (the trench depth)

- Bottom: 4µm

- Dual - bottom up

- Speed factor: 1x

- Threshold: 0.0%

- Light source:

- Levels: 2

- 176 -> 30 (might need to be set a little different)

- Gain: default

Result

Results of acceptance test no. 10

Sample: Transparent thin film thickness of 28 nm SiO2 on Si

Measurement:Film thickness measurement of transparent thin film

Acceptance criteria: SiO2 thickness 28±1 nm

Settings

- Objective: EPI 20x-N

- Model: SiO2 thermal

Result

The result was 28.7nm

Results of acceptance test no. 11

Sample: 120 nm nitride on 110 nm oxide on a silicon substrate

Measurement: Measurements of multiple stacks

Acceptance criteria: Within ±2% on each layer from an ellipsometer measurement (SiO2: 112nm, Si3N4: 139nm)

Settings Model layers use:

- SiO2_(therm)

- Si3N4

Result

- SiO2: 113.1nm

- Si3N4: 136.9nm

Results of acceptance test no. 12

Sample: Si with 1.4 µm patterned AZ-resist on 50µm pillars

Measurement: Film thickness measurements of transparent films on small structure

Acceptance criteria: Within ±1% from a standard profiler measurement.

Settings

Used Models -> Others -> Cauchy

Options -> Roughness -> change amplitude fitting

Result

Within limits

Results of acceptance test no. 13

Sample: Si wafer with poly-silicon layer

Measurement: Roughness repeatability, 3 successive measurements of the roughness

Acceptance criteria: Repeatability within 0.2%

Note: Because the surface roughness of the sample was very low and the noise/vibration level too high we could not obtain the specified repeatability.

Result

- The surface roughness (Ra) was 0.5nm

- The repeatability over 10 measurements was 34%

- The maximum deviation in roughness was 0.2nm

Se the number in the file below: