Specific Process Knowledge/Thermal Process/Oxidation: Difference between revisions

| (4 intermediate revisions by 2 users not shown) | |||

| Line 22: | Line 22: | ||

The standard recipes, quality control limits and results for the Boron Drive-in + Pre-dep furnace (A1) and the Phosphorus Drive-in furnace (A3) can be found here: | The standard recipes, quality control limits and results for the Boron Drive-in + Pre-dep furnace (A1) and the Phosphorus Drive-in furnace (A3) can be found here: | ||

*[[Specific Process Knowledge/Thermal Process/A1 | *[[Specific Process Knowledge/Thermal Process/A1 Bor Drive-in furnace|Standard recipes, QC limits and results for the Boron Drive-in + Predep furnace (A1)]] | ||

*[[Specific Process Knowledge/Thermal Process/A3 Phosphor Drive-in furnace|Standard recipes, QC limits and results for the Phosphorus Drive-in furnace (A3)]] | *[[Specific Process Knowledge/Thermal Process/A3 Phosphor Drive-in furnace|Standard recipes, QC limits and results for the Phosphorus Drive-in furnace (A3)]] | ||

| Line 68: | Line 68: | ||

!Generel description | !Generel description | ||

| | | | ||

*Dry and wet oxidation | *Dry and wet oxidation | ||

*Boron pre-deposition and boron drive-in are also done in the furnace | *Boron pre-deposition and boron drive-in are also done in the furnace | ||

| | | | ||

| Line 77: | Line 77: | ||

| | | | ||

*Dry and wet oxidation of 100 mm and 150 mm wafers | *Dry and wet oxidation of 100 mm and 150 mm wafers | ||

*Oxidation and annealing of wafers from the LPCVD furnaces and PECVD4 | *Oxidation and annealing of wafers from the LPCVD furnaces and PECVD4 | ||

| | | | ||

*Dry and wet oxidation and annealing of wafers from the wafer bonders and from PECVD4 and PECVD3 | *Dry and wet oxidation and annealing of wafers from the wafer bonders and from PECVD4 and PECVD3 | ||

| Line 432: | Line 432: | ||

</gallery> | </gallery> | ||

==Breakdown voltage measurements== | |||

In order to evaluate the quality of the oxide layers that can be grown in the oxidation furnaces, some breakdown voltage measurement have been made. | |||

The results can be found on this page: | The results can be found on this page: | ||

*[[Specific Process Knowledge/Thermal Process/Oxidation/Breakdown voltage measurements]] | *[[Specific Process Knowledge/Thermal Process/Oxidation/Breakdown voltage measurements]] | ||

Latest revision as of 13:40, 16 September 2025

Feedback to this page: click here

Unless otherwise stated, this page is written by DTU Nanolab internal

Oxidation

At DTU Nanolab we have eight furnaces and one RTP (rapid thermal processors) which can be used for thermal oxidation of silicon samples: Boron Drive-in and Pre-dep furnace (A1), Gate Oxide furnace (A2), Phosphorus Drive-in furnace (A3), Anneal-oxide furnace (C1), Anneal-Bond furnace (C3), Al-Anneal furnace (C4), Oxidation 8" furnace (E1), Resist Pyrolysis furnace and RTP Annealsys.

Thermal oxidation can take place either by a dry process or by a wet process, depending on what furnace that is used for the oxidation. The film quality for a dry oxide is better than the film quality for a wet oxide with regards to density and dielectric constant. However, the oxidation rate is slowest for dry oxidation.

- Dry oxidation is used to grow 5 nm - 300 nm of silicon oxide. Dry oxidation can be done in the A1, A2, A3, C1, C3, C4, E1 and Resist Pyrolysis furnaces.

- Wet oxidation is used to grow up to ~3 µm of silicon oxide. Wet oxidation can be done in the A1, A3, C1, C3 and E1 furnaces.

Wafers with oxide layers thicker than ~3 µm can normally not be made in the cleanroom and will have to be bought from somewhere else (but check the wafer shop first - there might be some on stock). It is NOT allowed to oxidize the same wafers two times to get a thicker layer than 3 µm without approval.

Thermal oxidation can done at temperatures up to 1050 C - 1150 C, depending on the furnace - and especially the diameter of the quartz tube in the furnace. At these high temperatures, the quartz tube might start to deform, so therefore the oxidation times are restricted:

- A1, A2, A3, C3 and C4 furnaces: Maximum allowed oxidation time at 1150 C: 8 hours

- A1, A2, A3, C1, C3, C4 and E1 furnaces: Maximum allowed oxidation time at 1100 C: 23 hours (this will result in ~3 um wet oxide)

- Resist Pyrolysis furnace: Maximum allowed oxidation time at 1050 C: 3 hours

The standard recipes, quality control limits and results for the Boron Drive-in + Pre-dep furnace (A1) and the Phosphorus Drive-in furnace (A3) can be found here:

- Standard recipes, QC limits and results for the Boron Drive-in + Predep furnace (A1)

- Standard recipes, QC limits and results for the Phosphorus Drive-in furnace (A3)

The wet oxidation rates for the Anneal-Bond furnace (C1) can be found here:

Standard recipes in the oxidation furnaces

The steps in the standard oxidation recipes in the A-stack furnaces (A1, A2 and A3) and the C-stack furnaces (C1, C3 and C4) can be found here:

Comparison of the oxidation furnaces

| Generel description |

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|---|

| Oxidation method |

|

|

|

|

|

|

|

|

|

| Annealing gas |

|

|

|

|

|

|

|

|

|

| Process temperature |

|

|

|

|

|

|

|

|

|

| Substrate and batch size |

|

|

|

|

|

|

|

|

|

| Allowed materials |

|

|

|

|

|

|

|

|

|

Oxidation curves

Color chart for oxide/nitride thickness

Generic calculator for wet/dry oxide thickness calculation

The following links give an approximate oxide time/thickness based on a general formula:

Deal-Grove parameters

By Kasper Reck-Nielsen February 2015

The following table contains linear and parabolic parameters for use in the Deal-Grove model for thermal oxidation. The parameters are obtained a least squares fit to data available in the furnace logbooks. Information on wafer orientation and doping concentration, which is not available in the logbooks, has not been included in calculating the parameters.

| Anneal Oxide | Anneal Bond | Boron Drive-in | Gate Oxide | Phosphor Drive-in | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Recipe | B [µm2/h] | B/A [µm/h] | RMSE [nm] | B [µm2/h] | B/A [µm/h] | RMSE [nm] | B [µm2/h] | B/A [µm/h] | RMSE [nm] | B [µm2/h] | B/A [µm/h] | RMSE [nm] | B [µm2/h] | B/A [µm/h] | RMSE [nm] |

| DRY900 | 0.000408 | 0.107 | Too little data | 0.0660 | 0.272 | 31 | 0.000390 | 0.154 | Too little data | 0.0028 | 0.079 | 4 (limited data) | 0.0507 | 0.884 | Too little data |

| DRY1000 | - | - | - | - | - | - | 0.465 | 0.838 | 20 | - | - | - | 0.641 | 1.45 | 41 |

| DRY1050 | 0.0111 | 0.526 | 27 | - | - | - | 0.0129 | 0.330 | 8 | 0.022 | 0.505 | 3 (limited data) | 0.0134 | 0.362 | 6 |

| DRY1100 | 0.020 | 0.930 | 10 | - | - | - | 0.0212 | 0.736 | 23 | - | - | - | 0.0313 | 0.553 | 14 |

| WET950 | - | - | - | - | - | 0.0716 | 1.25 | 12 | - | - | - | 0.110 | 1.17 | 11 | |

| WET1000 | 0.192 | 1.54 | 44 | - | - | 0.192 | 1.80 | 29 | - | - | - | 0.195 | 2.49 | 22 | |

| WET1050 | 0.487 | 0.965 | 29 | 0.477 | 0.899 | Too little data | 0.455 | 1.33 | 16 | - | - | - | 0.448 | 1.73 | 12 |

| WET1100 | 0.580 | 1.43 | 8 | - | - | - | 0.519 | 1.186 | 3 | - | - | - | 0.403 | 9.05 | 7 |

Wet Oxidation on <100>

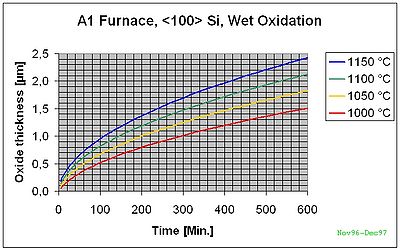

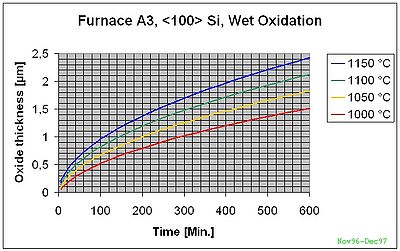

The curves below are based on measurements in our specific furnaces and give more accurate results. We will still recommend to make minimum one test run if the thickness is very important.

- Wet oxidation

-

A1 Furnace <100>-Si Wet Oxidation

-

A3 Furnace <100>-Si Wet Oxidation

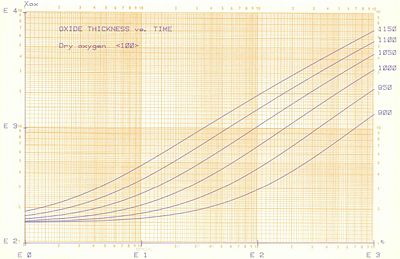

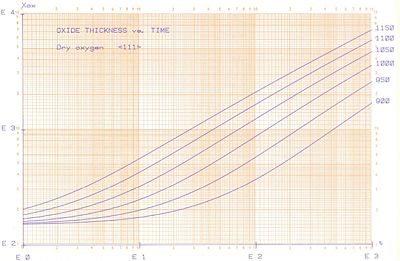

Dry Oxidation on <100> and <111> wafer

- Dry oxidation

-

Dry oxide on <100> wafer. The y-axis is in Å and the x-axis is in minutes.

-

Dry oxide on <111> wafer. The y-axis is in Å and the x-axis is in minutes.

Breakdown voltage measurements

In order to evaluate the quality of the oxide layers that can be grown in the oxidation furnaces, some breakdown voltage measurement have been made.

The results can be found on this page: