Specific Process Knowledge/Characterization/XPS/Carbon contamination: Difference between revisions

No edit summary |

No edit summary |

||

| (2 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Characterization/XPS/Carbon_contamination click here]''' | |||

<!-- Ok, jmli 20170627 --> | <!-- Ok, jmli 20170627 --> | ||

<!--Checked for updates on 2/10-2020 - ok/jmli --> | <!--Checked for updates on 2/10-2020 - ok/jmli --> | ||

<!--Checked for updates on 8/5-2023 - ok/jmli --> | |||

<!--Checked for updates on 4/9-2025 - ok/jmli --> | |||

{{Author-jmli1}} | |||

==Carbon Contamination== | ==Carbon Contamination== | ||

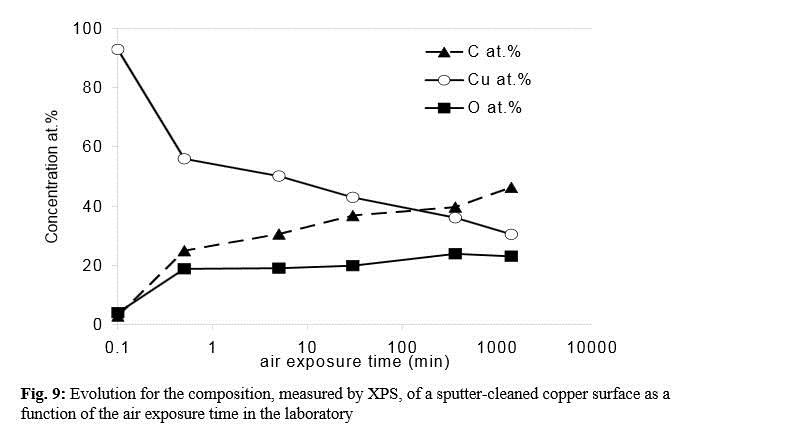

An unexpected carbon signal is often found in samples during XPS. The carbon typically originates from sample exposure to the air outside the XPS (e.g. the lab). Measurements of carbon contamination of a sputter cleaned Cu sample due to air exposure indicates that carbon contamination builds up to 20 At. % in approximately one minute. | An unexpected carbon signal is often found in samples during XPS. The carbon typically originates from sample exposure to the air outside the XPS (e.g. the lab). Measurements of carbon contamination of a sputter cleaned Cu sample due to air exposure indicates that carbon contamination builds up to 20 At. % in approximately one minute. | ||

Latest revision as of 09:35, 4 September 2025

Feedback to this page: click here

Unless otherwise stated, all content on this page was created by Jonas Michael-Lindhard, DTU Nanolab

Carbon Contamination

An unexpected carbon signal is often found in samples during XPS. The carbon typically originates from sample exposure to the air outside the XPS (e.g. the lab). Measurements of carbon contamination of a sputter cleaned Cu sample due to air exposure indicates that carbon contamination builds up to 20 At. % in approximately one minute.

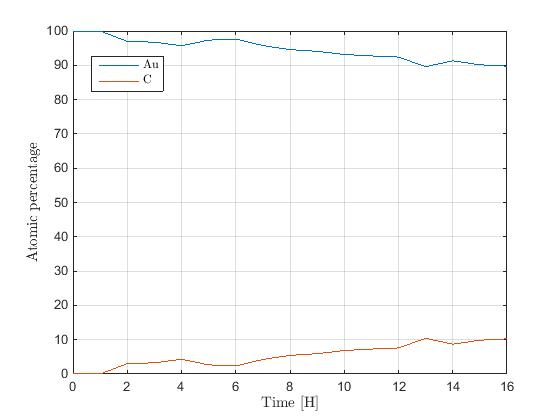

Measurements of the At. % of C on the Au-reference in the XPS after an initial sputter clean were conducted for 16 hours every hour. The results show that carbon is detectable after 1-2 hours and gradually builds up at a rate of approximately 0.6 At. percentage points per hour, i.e. much slower than if the sample is exposed to air. Thus carbon contamination on samples in the XPS typically originates from air exposure.