Specific Process Knowledge/Back-end processing/LatticeAxe: Difference between revisions

No edit summary |

|||

| (4 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:labadviser@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php/Specific_Process_Knowledge/Back-end_processing/LatticeAxe click here]''' | '''Feedback to this page''': '''[mailto:labadviser@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php/Specific_Process_Knowledge/Back-end_processing/LatticeAxe click here]''' | ||

'''Unless anything else is stated, everything on this page, text and pictures are made by DTU Nanolab.''' | |||

The equipment is placed in the left drawer underneath | == The Cleaver: LatticeAxe == | ||

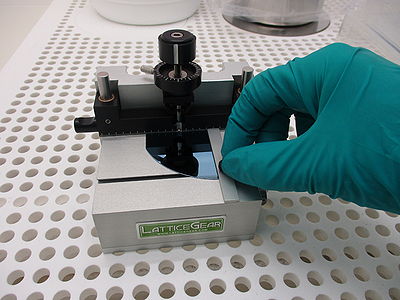

The Cleaver: LatticeAxe is designed for cleaving wafers into smaller pieces without leaving any particles on the sample. It works by making a small mark in the side of the sample that is then used as a start point for the cleaving. | |||

The equipment is placed in the left drawer underneath fume hood 5: Special purposes. When operated the the Cleaver: lattice axe should always be placed inside Fume hood 5. | |||

[[File:LatticeAxe placer prøve.JPG|400px]] | [[File:LatticeAxe placer prøve.JPG|400px]] | ||

| Line 18: | Line 22: | ||

The LatticeAxe can cleave samples from 100mm down to 10mm. In some cases it can even be used on larger samples please contact wetchemistry group for more information | The LatticeAxe can cleave samples from 100mm down to 10mm. In some cases it can even be used on larger samples please contact wetchemistry group for more information | ||

DTU-Nanolab has 3 different types of Cleavers see the Labadviser pages for the '''[http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Back-end_processing/FlexScribe FlexScribe]''' and the '''[http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Back-end_processing/FlipScribe | DTU-Nanolab has 3 different types of Cleavers see the Labadviser pages for the '''[http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Back-end_processing/FlexScribe FlexScribe]''' and the '''[http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Back-end_processing/FlipScribe FlipScribe]''' for more information. | ||

Latest revision as of 10:49, 30 September 2025

Feedback to this page: click here

Unless anything else is stated, everything on this page, text and pictures are made by DTU Nanolab.

The Cleaver: LatticeAxe

The Cleaver: LatticeAxe is designed for cleaving wafers into smaller pieces without leaving any particles on the sample. It works by making a small mark in the side of the sample that is then used as a start point for the cleaving.

The equipment is placed in the left drawer underneath fume hood 5: Special purposes. When operated the the Cleaver: lattice axe should always be placed inside Fume hood 5.

Approved Materials:

- Si

- Quartz

- Pyrex (Borofloat 33)

- GaAs

- InP

- Sapphire

The LatticeAxe can cleave samples from 100mm down to 10mm. In some cases it can even be used on larger samples please contact wetchemistry group for more information

DTU-Nanolab has 3 different types of Cleavers see the Labadviser pages for the FlexScribe and the FlipScribe for more information.