Specific Process Knowledge/Etch/IBE⁄IBSD Ionfab 300/IBE Ti etch: Difference between revisions

Appearance

No edit summary |

|||

| (4 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:labadviser@ | '''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Etch/IBE⁄IBSD_Ionfab_300/IBE_Ti_etch click here]''' | ||

<br> {{CC-bghe1}} | |||

==Results from the acceptance test in February 2011== | ==Results from the acceptance test in February 2011== | ||

'''Acceptance test for Ti etch:''' | '''Acceptance test for Ti etch :''' | ||

{| border="2" cellspacing="0" cellpadding="2" | {| border="2" cellspacing="0" cellpadding="2" | ||

|- | |- | ||

| Line 15: | Line 15: | ||

*50 mm SSP Si wafer | *50 mm SSP Si wafer | ||

*525 µm thick | *525 µm thick | ||

*Supplied by | *Supplied by Nanolab | ||

|. | |. | ||

|- | |- | ||

| Line 32: | Line 32: | ||

!style="background:silver; color:black" align="left" valign="top"|Features to be etched | !style="background:silver; color:black" align="left" valign="top"|Features to be etched | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

* | *300 nm - 3µm dots and lines + a square of 200µmx200µm | ||

|. | |. | ||

|- | |- | ||

!style="background:silver; color:black" align="left" valign="top"|Etch depth | !style="background:silver; color:black" align="left" valign="top"|Etch depth | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

* | *300nnm | ||

| | | | ||

*~270 nm | *~270 nm | ||

| Line 43: | Line 43: | ||

!style="background:silver; color:black" align="left" valign="top"|Etch rate | !style="background:silver; color:black" align="left" valign="top"|Etch rate | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

*> | *>80 nm/min | ||

| | | | ||

* | *22 nm/min +- 0.3nnm/min (one standard deviation) | ||

|- | |- | ||

!style="background:silver; color:black" align="left" valign="top"|Etch rate uniformity | !style="background:silver; color:black" align="left" valign="top"|Etch rate uniformity | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

*< | *<±2% | ||

| | | | ||

* | *±(0.2% ±0.2%) | ||

|- | |- | ||

!style="background:silver; color:black" align="left" valign="top"|Reproducibility | !style="background:silver; color:black" align="left" valign="top"|Reproducibility | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

*< | *<±2% | ||

| | | | ||

* | *±(0.8% ±0.5%) | ||

|- | |- | ||

!style="background:silver; color:black" align="left" valign="top"|Selectivity (Ti etch rate/ZEP etch rate) | !style="background:silver; color:black" align="left" valign="top"|Selectivity (Ti etch rate/ZEP etch rate) | ||

| Line 78: | Line 78: | ||

!Ti etch acceptance | !Ti etch acceptance | ||

|- | |- | ||

| | |Neutralizer current [mA] | ||

|550 | |550 | ||

|- | |- | ||

Latest revision as of 10:32, 4 September 2025

Feedback to this page: click here

The content on this page, including all images and pictures, was created by Berit Herstrøm @ DTU Nanolab (BGHE), unless otherwise stated.

Results from the acceptance test in February 2011

Acceptance test for Ti etch :

| . | Acceptance Criteria |

Acceptance Results |

|---|---|---|

| Substrate information |

|

. |

| Material to be etched |

|

. |

| Mask information |

|

. |

| Features to be etched |

|

. |

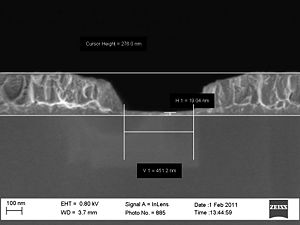

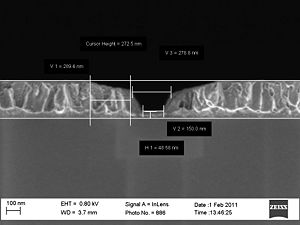

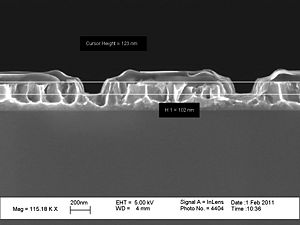

| Etch depth |

|

|

| Etch rate |

|

|

| Etch rate uniformity |

|

|

| Reproducibility |

|

|

| Selectivity (Ti etch rate/ZEP etch rate) |

|

|

| Etch profile |

|

|

Process parameters for the acceptance test

| Parameter | Ti etch acceptance |

|---|---|

| Neutralizer current [mA] | 550 |

| RF Power [W] | 1200 |

| Beam current [mA] | 500 |

| Beam voltage [V] | 600 |

| Beam accelerator voltage | 400 |

| Ar flow to neutralizer [sccm] | 6.0 |

| Ar flow to beam [sccm] | 6.0 |

| Rotation speed [rpm] | 20 |

| Stage angle [degrees] | 20 |