Specific Process Knowledge/Bonding/Wafer Bonder 02: Difference between revisions

Appearance

No edit summary |

mNo edit summary |

||

| (10 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

{{cc-nanolab}} | |||

'''Feedback to this page''': '''[mailto:labadviser@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php/Specific_Process_Knowledge/Bonding/Wafer_Bonder_02 click here]''' | '''Feedback to this page''': '''[mailto:labadviser@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php/Specific_Process_Knowledge/Bonding/Wafer_Bonder_02 click here]''' | ||

<br> | |||

<br> | |||

=Wafer Bonder 02= | |||

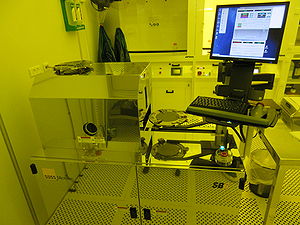

[[Image: | [[Image:wafer bonder2.jpg|300x300px|thumb|Wafer Bonder 02: Positioned in cleanroom E-4]] | ||

The | The Wafer bonder 02 is a system for bonding. 3 different types of [[Specific Process Knowledge/Bonding|bonding]] can be done: Anodic, Eutectic and Fusion. Furthermore it is possible to align the wafers one wishes to bond. It is also possible to process and align pieces. | ||

'''The user manual, quality control procedure and results, user APV(s), and contact information can be found in LabManager:''' | '''The user manual, quality control procedure and results, user APV(s), and contact information can be found in LabManager:''' | ||

Equipment info in [http://labmanager.danchip.dtu.dk/function.php?module=Machine&view=view&mach= | Equipment info in [http://labmanager.danchip.dtu.dk/function.php?module=Machine&view=view&mach=366| LabManager] | ||

<br clear="all" /> | <br clear="all" /> | ||

==Process information== | |||

====Types of Bonding==== | ====Types of Bonding==== | ||

*[[Specific Process Knowledge/Bonding/Eutectic bonding|Eutectic bonding]] | *[[Specific Process Knowledge/Bonding/Eutectic bonding|Eutectic bonding]] | ||

*[[Specific Process Knowledge/Bonding/Fusion bonding|Fusion bonding]] | *[[Specific Process Knowledge/Bonding/Fusion bonding|Fusion bonding]] | ||

*[[Specific Process Knowledge/Bonding/Anodic bonding|Anodic bonding]] | *[[Specific Process Knowledge/Bonding/Anodic bonding|Anodic bonding]] | ||

<br> | |||

==Overview of the performance of the Wafer Bonder 02 and some process related parameters== | |||

==Overview of the performance of the | |||

{| border="2" cellspacing="0" cellpadding="10" | {| border="2" cellspacing="0" cellpadding="10" | ||

|- | |- | ||

!style="background:silver; color:black;" align="left"|Purpose | !style="background:silver; color:black;" align="left"|Purpose | ||

|style="background:LightGrey; color:black"| | |style="background:LightGrey; color:black"|Bonding | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

*Eutectic bonding | *Eutectic bonding | ||

*Fusion bonding | *Fusion bonding | ||

*Anodic bonding | *Anodic bonding | ||

|- | |- | ||

!style="background:silver; color:black" align="left"|Performance | !style="background:silver; color:black" align="left"|Performance | ||

|style="background:LightGrey; color:black"|Alignment accuracy | |style="background:LightGrey; color:black"|Alignment accuracy | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

*± | *± 2 microns for IR alignment | ||

*± | *± 5 microns for backside alignment | ||

|- | |- | ||

|- | |- | ||

| Line 49: | Line 44: | ||

|style="background:LightGrey; color:black"|Process pressure | |style="background:LightGrey; color:black"|Process pressure | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

*~5<math>\cdot</math>10<sup>-4</sup>mbar - | *~5<math>\cdot</math>10<sup>-4</sup>mbar - 1000mbar | ||

|- | |- | ||

|style="background:LightGrey; color:black"|Piston Force | |style="background:LightGrey; color:black"|Piston Force | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

*Depending on the area, for 4" wafers 200- | *Depending on the area, for 4" wafers 200-6000 mbar. | ||

|- | |- | ||

!style="background:silver; color:black" align="left" valign="top" rowspan="3"|Substrates | !style="background:silver; color:black" align="left" valign="top" rowspan="3"|Substrates | ||

|style="background:LightGrey; color:black"|Batch size | |style="background:LightGrey; color:black"|Batch size | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

*One | *One wafer per run | ||

*Pieces | *Pieces | ||

|- | |- | ||

| style="background:LightGrey; color:black"|Substrate material allowed | | style="background:LightGrey; color:black"|Substrate material allowed | ||

| Line 72: | Line 67: | ||

*Silicon (oxy)nitride | *Silicon (oxy)nitride | ||

*Poly Silicon | *Poly Silicon | ||

*Metals: Au, Sn, Ag, Al, Ti | |||

*Metals: Au, Sn, Ag, Al, Ti | |||

|- | |- | ||

|} | |} | ||

Latest revision as of 18:17, 27 May 2025

The content on this page, including all images and pictures, was created by DTU Nanolab staff, unless otherwise stated.

Feedback to this page: click here

Wafer Bonder 02

The Wafer bonder 02 is a system for bonding. 3 different types of bonding can be done: Anodic, Eutectic and Fusion. Furthermore it is possible to align the wafers one wishes to bond. It is also possible to process and align pieces.

The user manual, quality control procedure and results, user APV(s), and contact information can be found in LabManager: Equipment info in LabManager

Process information

Types of Bonding

| Purpose | Bonding |

|

|---|---|---|

| Performance | Alignment accuracy |

|

| Process parameter range | Process Temperature |

|

| Process pressure |

| |

| Piston Force |

| |

| Substrates | Batch size |

|

| Substrate material allowed |

| |

| Material allowed on the substrate |

|