LabAdviser: Difference between revisions

No edit summary |

|||

| (187 intermediate revisions by 11 users not shown) | |||

| Line 1: | Line 1: | ||

__notoc__ | __notoc__ | ||

[[image:Til LA forside 2024-05-03 161145.png|right|500x500px|thumb|Photos: DTU Nanolab]] | |||

{{CC1}} | |||

<!--LabAdviser is a process handbook for equipment and processes at the cleanroom facilities and the characterisation facilities in building 314/307. The function and capacity of each piece of equipment is described and general process steps, eg photolithography procedures, are clarified. LabAdviser is meant to advise you to a good starting point for your cleanroom process for further optimization to meet your needs. To enter LabAdviser you need to '''log in with your DTU login'''. LabAdviser is only editable for DTU Nanolab employees. If you need further information about certain machinery or processes, please contact Nanolab personnel. Any feedback you might have on LabAdviser is welcome and can be given by mail to the LabAdviser mailbox: [mailto:labadviser@nanolab.dtu.dk labadviser@nanolab.dtu.dk]--> | |||

LabAdviser is a process handbook for equipment and processes at the | LabAdviser is a wiki designed for users of the DTU Nanolab facilities. If you are not a current user you are free to surf around, and also [https://www.nanolab.dtu.dk/english '''please take a look at our homepage''']. You can also take a [https://www.nanolab.dtu.dk/capabilities/cleanroom-3d-tour'''virtual tour of the DTU Nanolab cleanroom facility'''] or explore our [https://www.youtube.com/channel/UCJhdUTUJRDNODNiC3V95RQQ '''YouTube channel'''] with a selection of training videos. <br> | ||

LabAdviser contains information about | |||

*Equipment for micro- and nanofabrication in the DTU Nanolab cleanroom facility in building 346 and surroundings (in building 346 and 347) | |||

*Characterization equipment, primarily electron microscopy, in building 314 and 307. | |||

*Fabrication steps in micro- and nanofabrication that take place at the cleanroom fabrication facility and surroundings; and | |||

*Electron microscopy methods that take place in building 314/307. | |||

An overview of the equipment in these facilities is given and some fabrication process flows and singles fabrication steps are described. In general LabAdviser is meant to help you find the right equipment and give you a good starting point for micro- and nanofabrication as well as for electron microscopy. This should not replace communication with the staff of the facilities but we recommend reading LabAdviser material as preparation before contacting staff. To be able to edit LabAdviser you need to '''log in with your DTU login''' (only for staff of the facilities). If you need further information about certain machinery or processes, please contact the relevant staff. Feedback and input is welcome by email to: [mailto:labadviser@nanolab.dtu.dk labadviser@nanolab.dtu.dk] | |||

<br> | <br> | ||

'''News in LabAdviser:''' <br/> | '''News in LabAdviser:''' <br/> | ||

The latest | <!-- *The latest LabAdviser update: [[Media:Monthly LabAdviser update 20231110.docx|LabAdviser update sent out 2023-11-10]] <br> --> | ||

Slides from the | *Slides from the latest Tech Forum: [https://labmanager.dtu.dk/function.php?module=PeriodicDocument&view=docs&page_id=397 Tech Forum slides in LabManager - requires login] <br/> | ||

<br/> | |||

== Contents == | |||

[[Image:Virtual tour in the clean room.JPG|right|300px|thumb|Take a virtual tour in the DTU Nanolab cleanroom [[https://www.nanolab.dtu.dk/capabilities/cleanroom-3d-tour]]]] | |||

[[Image:YouTube.JPG|right|300px|thumb|DTU Nanolab on YouTube [[https://www.youtube.com/channel/UCJhdUTUJRDNODNiC3V95RQQ]]]] | |||

*'''[[/Introduction to LabAdviser and Processing|Introduction to LabAdviser and Micro/Nano Fabrication]]''' | |||

*'''[[/Introduction to LabAdviser and Processing|Introduction to LabAdviser and | |||

*'''[[/Introduction to LabManager|Introduction to LabManager]]''' | *'''[[/Introduction to LabManager|Introduction to LabManager]]''' | ||

*'''[[/Process flow approval|Process flow approval]]''' | *'''[[/Process flow approval|Process flow template & approval]] (fabrication)''' | ||

*'''[[Specific Process Knowledge]]''' | |||

<!-- *'''[[/CEN|Characterization in building 314/307 - OLD]] --> | |||

*'''[[/314|Characterization in building 314/307]] | |||

*'''[[Specific Process Knowledge|Micro and Nano Fabrication Overview ]]''' | |||

*'''[[/Courses |Courses (Introduction course, Tool Package Training's (TPT))]] | |||

*'''[[LabAdviser/Technology Research|Some DTU Nanolab Projects - Technology Research]]''' | |||

<!-- *'''[[/Equipment List|Equipment List]]''' --> | <!-- *'''[[/Equipment List|Equipment List]]''' --> | ||

*'''[[Surveys and statistics|Surveys, statistics, monthly LabAdviser updates and other info.]]''' | *'''[[Surveys and statistics|Surveys, statistics, monthly LabAdviser updates and other info.]]''' | ||

*'''[[How to add information to LabAdviser]]''' | *'''[[How to add information to LabAdviser]]''' | ||

| Line 25: | Line 41: | ||

*'''[[/Technology Research|Under Construction]]''' | *'''[[/Technology Research|Under Construction]]''' | ||

--> | --> | ||

<br clear="all" /> | <br clear="all" /> | ||

==Overview of micro and nano fabrication steps - a guide to where you can find fabrication information in LabAdviser== | |||

''All drawings in this section done by Jesper Hanberg @DTU Nanolab'' | |||

=== Click on [show] and see choices to the right === | |||

{| style="color: black;vertical-align:top" width="100%" border=0 cellpadding="4" cellspacing="0" | {| style="color: black;vertical-align:top" width="100%" border=0 cellpadding="4" cellspacing="0" | ||

| colspan="2" | | | colspan="2" | | ||

| Line 53: | Line 71: | ||

! class="hideImage" width="150" | Characterize your sample [[file:jehanCharacterize.png|130px|frameless ]] | ! class="hideImage" width="150" | Characterize your sample [[file:jehanCharacterize.png|130px|frameless ]] | ||

! class="hideImage" width="150" | Pack your sample [[file:jehanPack.png|130px|frameless ]] | ! class="hideImage" width="150" | Pack your sample [[file:jehanPack.png|130px|frameless ]] | ||

! class="hideImage" width="150"| Process flow examples | ! class="hideImage" width="150" | Process flow examples [[file:processflow_b.png|130px|frameless ]] | ||

|- | |- | ||

|} | |} | ||

| Line 59: | Line 77: | ||

| style="color:black; width: 50%; vertical-align: top;"| | | style="color:black; width: 50%; vertical-align: top;"| | ||

{| class="wikitable hideable hidden" border="1" cellspacing="0" cellpadding="0" align="left" width="400px" style="float:right;" | {| class="wikitable hideable hidden" border="1" cellspacing="0" cellpadding="0" align="left" width="400px" style="float:right;" | ||

! style="text-align:right;" | [[image:DUV6.jpg|center|400px]] | ! style="text-align:right;" | [[image:DUV6.jpg|center|400px|thumb|Photo: DTU Nanolab]] | ||

|- | |- | ||

|} | |} | ||

| Line 90: | Line 108: | ||

|} | |} | ||

{| class="wikitable hideable hidden" border="1" cellspacing="1" cellpadding="2" align="left" width="430px" | {| class="wikitable hideable hidden" border="1" cellspacing="1" cellpadding="2" align="left" width="430px" | ||

!colspan="3" style="text-align:left;" | [[image:Dry your sample.png| | !colspan="3" style="text-align:left;" | [[image:Dry your sample.png|x130px|Dry your sample]] Dry your sample | ||

|- | |- | ||

!Entry page in LabAdviser | !Entry page in LabAdviser | ||

| Line 133: | Line 151: | ||

|- | |- | ||

|E-beam evaporation | |E-beam evaporation | ||

|Metals: Ti, Cr, Al, Ni, Pt, Au, Mo, Pd, Ag, Cu, W, Ta <br> | |Metals: Ti, Cr, Al, Ni, Pt, Au, Mo, Nb, Pd, Ag, Cu, W, Ta <br> | ||

Semiconductors: Si, Ge <br> | Semiconductors: Si, Ge <br> | ||

Oxides: SiO<sub>2</sub>, TiO<sub>2</sub> <br> | Oxides: SiO<sub>2</sub>, TiO<sub>2</sub> <br> | ||

| Line 278: | Line 296: | ||

|[[Specific Process Knowledge/Imprinting|Imprinting]] | |[[Specific Process Knowledge/Imprinting|Imprinting]] | ||

|TOPAS, PMMA | |TOPAS, PMMA | ||

|- | |||

|Hot Embosser | |||

|Topas, PP, PE, PS, PC, PMMA, ... | |||

|- | |- | ||

|[[Specific Process Knowledge/Lithography|Lithography definition]] | |[[Specific Process Knowledge/Lithography|Lithography definition]] | ||

| Line 360: | Line 381: | ||

|} | |} | ||

{| class="wikitable hideable hidden" border="1" cellspacing="1" cellpadding="2" align="left" width="430px" | {| class="wikitable hideable hidden" border="1" cellspacing="1" cellpadding="2" align="left" width="430px" | ||

!colspan="3" style="text-align:left;" | | !colspan="3" style="text-align:left;" | Process flow examples | ||

|- | |- | ||

!Entry page in LabAdviser | !Entry page in LabAdviser | ||

| Line 367: | Line 388: | ||

|[[LabAdviser/Introduction_to_LabAdviser_and_Processing|Introduction to LabAdviser and Processing]] | |[[LabAdviser/Introduction_to_LabAdviser_and_Processing|Introduction to LabAdviser and Processing]] | ||

|Solar cell flow | |Solar cell flow | ||

|- | |||

|[[Process_flow_approval|Process flow approval]] | |||

|Info on process flow review | |||

|- | |- | ||

|[[Specific Process Knowledge/Lithography/UVLithography#Resist Overview|UV Lithography#Resist Overview]] | |[[Specific Process Knowledge/Lithography/UVLithography#Resist Overview|UV Lithography#Resist Overview]] | ||

| Line 382: | Line 406: | ||

<br> | <br> | ||

== | == Contact Information for the DTU Nanolab fabrication part == | ||

{{DanchipInfo}} | {{DanchipInfo}} | ||

<!-- The template called DanchipInfo has the address: | |||

http://labadviser.nanolab.dtu.dk/index.php/Template:DanchipInfo --> | |||

---- | ---- | ||

<br> | <br clear="all"/> | ||

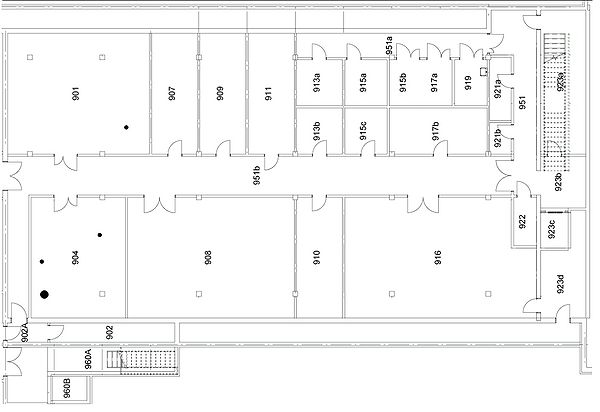

==DTU Nanolab Fabrication Cleanroom Naming and Phone Numbers== | |||

===Cleanroom building 346 ground floor=== | |||

{| style="color: black;" width="100%" | {| style="color: black;" width="100%" | ||

| colspan="2" | | | colspan="2" | | ||

| Line 401: | Line 428: | ||

[[image: | [[image:Cleanroom_naming_2017.jpg|500px|thumb|Drawing: DTU CAS Digital]] | ||

|} | |} | ||

| Line 425: | Line 452: | ||

|- | |- | ||

|-style="background: | |-style="background:LightGrey; color:black" | ||

!Ax2 | !Ax2 | ||

|At the Lesker | |At the Lesker | ||

| Line 432: | Line 459: | ||

|- | |- | ||

|-style="background: | |-style="background:WhiteSmoke; color:black" | ||

!A-5 | !A-5 | ||

|In the corner near the furnace/plasma asher | |In the corner near the furnace/plasma asher | ||

| Line 474: | Line 501: | ||

|- | |- | ||

|-style="background:WhiteSmoke; color:black" | |-style="background:WhiteSmoke; color:black" | ||

!E-5 | !E-5/E-4 | ||

|By | |By the MLAs in E-5, by mask aligner in E-4 | ||

|55 946 | |55 946 | ||

|- | |- | ||

| Line 495: | Line 522: | ||

|-style="background:LightGrey; color:black" | |-style="background:LightGrey; color:black" | ||

!F-2 | !F-2 | ||

| | |To the right of the XRD and Ellipsometer | ||

|55 941 | |55 941 | ||

|- | |- | ||

| Line 504: | Line 531: | ||

|55 947 | |55 947 | ||

|- | |- | ||

|- | |- | ||

|-style="background:LightGrey; color:black" | |-style="background:LightGrey; color:black" | ||

! | !Basement 901 | ||

|Injection molder room in the basement | |Injection molder room in the basement | ||

|55 812 | |55 812 | ||

|- | |||

|-style="background:LightGrey; color:black" | |||

!Basement 904 | |||

|To the right of the AFM | |||

|55 813 | |||

|- | |- | ||

|} | |} | ||

| Line 521: | Line 548: | ||

<br clear="all" /> | <br clear="all" /> | ||

==DTU | ===Basement building 346 phase 1=== | ||

[[File:Basement 346 phase 1.jpg|left|600px|thumb|Drawing: DTU CAS Digital]] <br> | |||

<br clear="all" /> | |||

==DTU Nanolab building 314 and Phone Numbers== | |||

{| style="color: black;" width="100%" | {| style="color: black;" width="100%"; "text-align: center | ||

| colspan="2" | | | colspan="2" | | ||

|- | |- | ||

| Line 535: | Line 566: | ||

[[File:CEN building.jpg|600px]] | [[File:CEN building.jpg|600px|left|thumb|Drawing: DTU CAS Digital]] | ||

|} | |} | ||

| Line 562: | Line 593: | ||

|-style="background:silver; color:black" | |-style="background:silver; color:black" | ||

!Room number | !Room number | ||

! | !Description | ||

!Phone number | !Phone number | ||

|- | |- | ||

| Line 569: | Line 600: | ||

|-style="background:WhiteSmoke; color:black" | |-style="background:WhiteSmoke; color:black" | ||

!314-011 | !314-011 | ||

| | |QFEG 200 Cryo ESEM | ||

|56 406 | |56 406 | ||

|- | |- | ||

|- | |- | ||

|-style="background: | |-style="background:LightGrey; color:black" | ||

!314-014 | !314-014 | ||

| | |Tecnai T20 | ||

|56 407 | |56 407 | ||

|- | |- | ||

|- | |- | ||

|-style="background: | |-style="background:WhiteSmoke; color:black" | ||

!314- | !314-032 | ||

|Prep room | |Prep room 1 | ||

|No phone | |No phone | ||

|- | |- | ||

| Line 589: | Line 620: | ||

|-style="background:LightGrey; color:black" | |-style="background:LightGrey; color:black" | ||

!314-034 | !314-034 | ||

| | |AFEG 250 ESEM | ||

|56 414 | |56 414 | ||

|- | |- | ||

| Line 597: | Line 628: | ||

!314-037 | !314-037 | ||

|Titan ETEM | |Titan ETEM | ||

|56 | |56 418 | ||

|- | |- | ||

| Line 603: | Line 634: | ||

|-style="background:LightGrey; color:black" | |-style="background:LightGrey; color:black" | ||

!314-040 | !314-040 | ||

|Prep room (Bio) | |Prep room 2 (Bio) | ||

|56 413 | |56 413 | ||

|- | |- | ||

| Line 611: | Line 642: | ||

!314-042 | !314-042 | ||

|Titan ATEM | |Titan ATEM | ||

| | |56 409 | ||

|- | |- | ||

| Line 617: | Line 648: | ||

|-style="background:LightGrey; color:black" | |-style="background:LightGrey; color:black" | ||

!314-060 | !314-060 | ||

|Nova | |Nova NanoSEM 600 | ||

|56 412 | |56 412 | ||

|- | |- | ||

| Line 624: | Line 655: | ||

|-style="background:WhiteSmoke; color:black" | |-style="background:WhiteSmoke; color:black" | ||

!314-061 | !314-061 | ||

|Helios | |Helios Nanolab | ||

|56 411 | |56 411 | ||

|- | |- | ||

Latest revision as of 15:13, 1 November 2024

Unless otherwise stated, this page is written by DTU Nanolab internal

LabAdviser is a wiki designed for users of the DTU Nanolab facilities. If you are not a current user you are free to surf around, and also please take a look at our homepage. You can also take a virtual tour of the DTU Nanolab cleanroom facility or explore our YouTube channel with a selection of training videos.

LabAdviser contains information about

- Equipment for micro- and nanofabrication in the DTU Nanolab cleanroom facility in building 346 and surroundings (in building 346 and 347)

- Characterization equipment, primarily electron microscopy, in building 314 and 307.

- Fabrication steps in micro- and nanofabrication that take place at the cleanroom fabrication facility and surroundings; and

- Electron microscopy methods that take place in building 314/307.

An overview of the equipment in these facilities is given and some fabrication process flows and singles fabrication steps are described. In general LabAdviser is meant to help you find the right equipment and give you a good starting point for micro- and nanofabrication as well as for electron microscopy. This should not replace communication with the staff of the facilities but we recommend reading LabAdviser material as preparation before contacting staff. To be able to edit LabAdviser you need to log in with your DTU login (only for staff of the facilities). If you need further information about certain machinery or processes, please contact the relevant staff. Feedback and input is welcome by email to: labadviser@nanolab.dtu.dk

News in LabAdviser:

- Slides from the latest Tech Forum: Tech Forum slides in LabManager - requires login

Contents

- Introduction to LabAdviser and Micro/Nano Fabrication

- Introduction to LabManager

- Process flow template & approval (fabrication)

- Characterization in building 314/307

- Micro and Nano Fabrication Overview

- Courses (Introduction course, Tool Package Training's (TPT))

- Some DTU Nanolab Projects - Technology Research

- Surveys, statistics, monthly LabAdviser updates and other info.

- How to add information to LabAdviser

Overview of micro and nano fabrication steps - a guide to where you can find fabrication information in LabAdviser

All drawings in this section done by Jesper Hanberg @DTU Nanolab

Click on [show] and see choices to the right

Contact Information for the DTU Nanolab fabrication part

In order to get the quickest response to training requests, process approvals, questions etc. please use the following mailboxes to DTU Nanolab (formerly known as Danchip).

| Subject | Description | |

| Training and Process Flow | training@nanolab.dtu.dk | All requests regarding equipment training and process flows. Please add your Name to the subject line. Note: Requests are commonly answered within 2 workdays. |

| E-beam training | e-beam@nanolab.dtu.dk | Requests regarding training on JEOL JBX-9500FSZ or Raith Eline e-beam systems. Please study the material on the EBL Labadviser pages beforehand. |

| E-beam Cassette loading | e-beamload@nanolab.dtu.dk | Requests regarding cassette loading on JEOL JBX-9500FSZ. |

| General inquiries | nanolabsupport@nanolab.dtu.dk | Inquiries related to machines, cleanroom access, Mask review, tool changes, and others. Please add your Name to the subject line. Note: Requests are commonly answered within 2 workdays. |

| Metal Wishes | metal@nanolab.dtu.dk | Requests for change of metal in Thin Film Deposition equipment. See current and future materials in statuslog of the respective machines.

|

| Gas-related Requests | DCH-Gas@nanolab.dtu.dk | All topics gas-related (issues, information regarding ordering, delivery, changing etc). Mostly for internal DTU Nanolab use. |

| LabAdviser Mailbox | labadviser@nanolab.dtu.dk | Any questions or feedback to LabAdviser. |

| Commercial Inquiries | sales@nanolab.dtu.dk | For all inquiries regarding in-sourcing, commercial applications, rent of cleanroom space, etc |

DTU Nanolab Fabrication Cleanroom Naming and Phone Numbers

Cleanroom building 346 ground floor

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||

Basement building 346 phase 1

DTU Nanolab building 314 and Phone Numbers

|

|

||||||||||||||||||||||||||||||||||||||||