Specific Process Knowledge/Etch/DRIE-Pegasus/Pegasus-4/SiO2 Etch: Difference between revisions

| (42 intermediate revisions by the same user not shown) | |||

| Line 18: | Line 18: | ||

</gallery> | </gallery> | ||

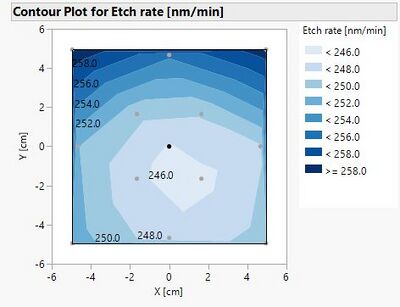

===Uniformity results with SiO2_res_10=== | |||

[[File:SiO2 etch uniformity DOE3_10.JPG|400px|thumb|left|Etched for 3min56s, average etch rate: 250 nm/min +- 2.9% ]] | |||

<br clear="all"/> | |||

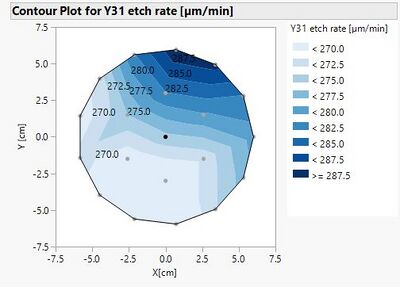

===Results with SiO2_res_10 and EM=== | |||

[[File:Contour Plot Y31 EM_02_30 white to blue.jpg|400px|thumb|left|Etched with EM:02/30 for 2min, average etch rate: 275 nm/min +- 4.5%. The electro magnets changed the uniformity pattern and made it a bit worse ]] | |||

<br clear="all"/> | |||

<gallery caption="Recipe name: SiO2_res_10, Recipe no. 10+EM coils: C06445_02 coil_2500W, platen:300W, EM:02/30A, He/C4F8= 17.5, C4F8/H2=1, Pressure:8.8mTorr, C4F8:25.6sccm, He:448.7sccm, H2:25.6sccm, 3:56 min " perrow="5"> | |||

File:C09936_05.jpg | |||

File:C09936_04.jpg | |||

File:C09936_03.jpg | |||

File:C09936_02.jpg | |||

File:C09936_01.jpg | |||

</gallery> | |||

Using the electromagnetic coil on the recipe SiO2_res_10 gave higher etch rate on this chip that was placed in the center of a 6" wafer. The Etch profile is more angles. | |||

*I few more test with resist mask and electromagnets can be found here: [[/EM with resist mask|EM with resist mask]] | |||

<br clear="all"/> | |||

==SiO2 Etch using aSi as masking material== | ==SiO2 Etch using aSi as masking material== | ||

{{CC-bghe2}} <br> | {{CC-bghe2}} <br> | ||

I | I was starting up development of SiO2 etch using aSi as masking material. This is on pause because the results did not look promishing on high aspect ratio structures wit DUV pattern due to large faceting on the aSi mask. I turned to Cr mask instead <br> | ||

The samples I use are: | The samples I use are: | ||

*6" Si afters with oxide (2µm), | *6" Si afters with oxide (2µm), | ||

| Line 57: | Line 78: | ||

Image:dose270_no2_22.jpg |270 J/m2 1000nm/494nm | Image:dose270_no2_22.jpg |270 J/m2 1000nm/494nm | ||

</gallery> | |||

==SiO2 etch with Cr mask== | |||

{{CC-bghe2}} <br> | |||

*[[/Cr mask|More tests with Cr mask]] | |||

===SiO2 etch with Cr mask 100 nm and with 500 nm for the resist for the Cr etch=== | |||

Barc etch and Cr etch were done in ICP metal using end point detection. The sample was a full 6" wafer | |||

<gallery caption="SiO2_res_10 2x5:00 min with 3 min TDESC clean in between 100 nm Cr mask, with 500 nm resist" widths="200px" heights="200px" perrow="6"> | |||

File:C041630_center_07.jpg | |||

File:C041630_center_08.jpg | |||

File:C041630_center_09.jpg | |||

File:C041630_center_10.jpg | |||

File:C041630_center_11.jpg | |||

File:C041630_center_22.jpg | |||

</gallery> | |||

<gallery widths="200px" heights="200px" perrow="6"> | |||

File:C041630_center_02.jpg | |||

File:C041630_center_03.jpg | |||

File:C041630_center_04.jpg | |||

File:C041630_center_05.jpg | |||

File:C041630_center_06.jpg | |||

</gallery> | |||

<gallery caption="SiO2_res_10 5:00 min 100 nm Cr mask, with 500 nm resist, resist/Cr stripped after etch in plasma asher 35min" widths="250px" heights="250px" perrow="4"> | |||

File:S0411376_profile_20.jpg| 200nm/400nm | |||

File:S0411376_profile_13.jpg|250nm/500nm | |||

File:S0411376_profile_14.jpg| 400nm/800nm | |||

File:S0411376_profile_15.jpg|500nm/1000nm | |||

File:S0411376_profile_17.jpg|1000nm/2000nm | |||

File:S0411376_profile_18.jpg|2000nm/4000nm | |||

</gallery> | |||

===Testing with electromagnetic coils /Cr mask=== | |||

{{CC-bghe2}} <br> | |||

When testing with decreased platen power on the SiO2_10 standard recipe the uniformity got very bad. I then tested with the electromagnetics coil to see if that could affect the uniformity. There is an outer coil that can be varied between 0 A and 10 A and an inner coil that can be varied between 0 A and 30 A. The first tests were done on Si/SiO2(1µm) without pattern and measured on the ellipsometer. | |||

{| border="2" cellspacing="2" cellpadding="3" | |||

!Parameter | |||

|Recipe name: '''no 10 with lower platen power''' | |||

|- | |||

|Coil Power [W] | |||

|2500 | |||

|- | |||

|Platen Power [W] | |||

|200 | |||

|- | |||

|Platen temperature [<sup>o</sup>C] | |||

|20 | |||

|- | |||

|H2 flow [sccm] | |||

|25.6 | |||

|- | |||

|C<sub>4</sub>F<sub>8</sub> flow [sccm] | |||

|25.6 | |||

|- | |||

|He flow [sccm] | |||

|448.7 | |||

|- | |||

|Pressure | |||

|Fully open APC valve (8-9 mTorr) | |||

|- | |||

|Electromagnetic coils (EM) 'outer coil' / 'inner coil' | |||

|'0-10 A' / '0-30 A' | |||

|- | |||

|} | |||

<gallery caption="EM tests" perrow="3" widths="400px" heights="300px"> | |||

File:Contour Plot Y15 EM_0_0.JPG| Etch time: 2 min, Average etch rate: 100.2 nm/min, range:+-55.1% | |||

File:Contour Plot Y16 EM_10_30.JPG|Etch time: 2 min, Average etch rate: 100.5 nm/min, range:+-32.6% | |||

File:Contour Plot Y27 EM_10_0.JPG|Etch time: 2 min, Average etch rate: 100.8 nm/min, range:+-50.8% | |||

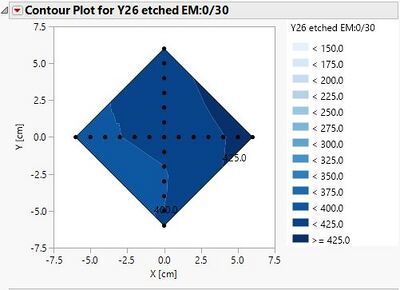

File:Contour Plot Y26 EM_0_30.JPG|Etch time: 2 min, Average etch rate: 203.8 nm/min, range:+-6.1% | |||

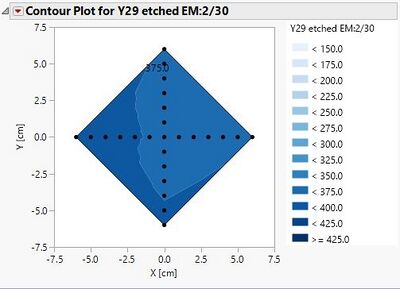

File:Contour Plot Y29 EM_2_30.JPG|Etch time: 2 min, Average etch rate: 186.2 nm/min, range:+-3.2% | |||

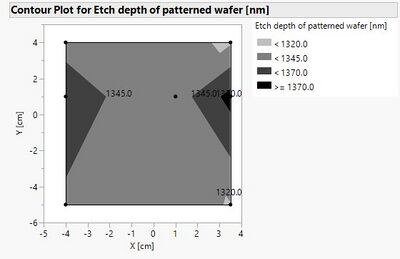

File:Contour Plot patterned wafer EM_2_30.JPG| Etch time: 6 min on patterned wafer with different measurement points, <100 nm Cr mask is still on, EM_2/30, Average etch rate: 207-223 nm/min depending on how much Cr mask is left, range:+-2.3% | |||

</gallery> | |||

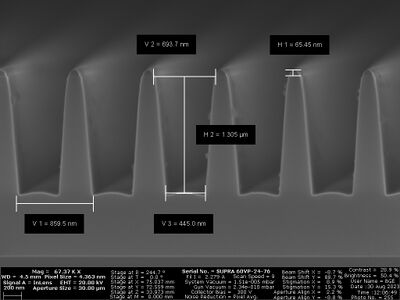

<gallery caption="EM tests with Cr mask on full wafer 6 min etch" perrow="3" widths="400px" heights="300px"> | |||

File:C09721_center_05.jpg | |||

File:C09721_center_07.jpg | |||

File:C09721_center_10.jpg | |||

File:C09721_center_18.jpg | |||

File:C09721_center_21.jpg | |||

File:C09721_center_22.jpg | |||

</gallery> | </gallery> | ||

Latest revision as of 16:00, 5 February 2024

SiO2 Etch using resist as masking material

Unless otherwise stated, all content in this section was done by Berit Herstrøm, DTU Nanolab

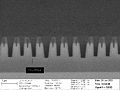

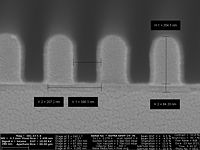

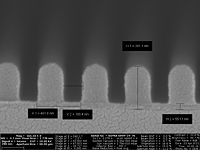

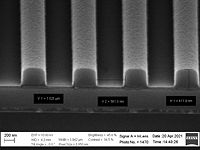

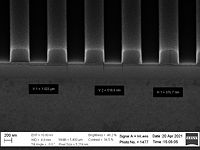

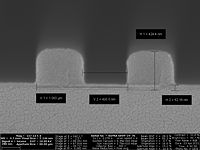

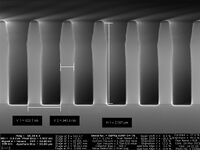

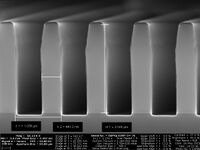

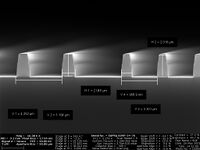

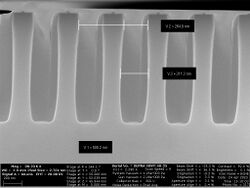

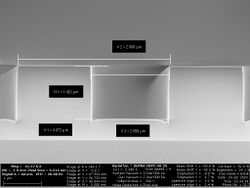

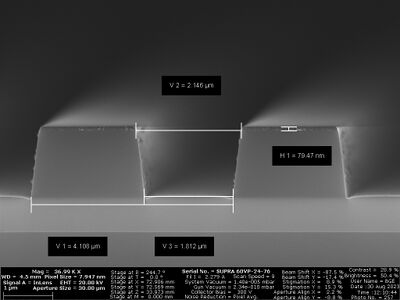

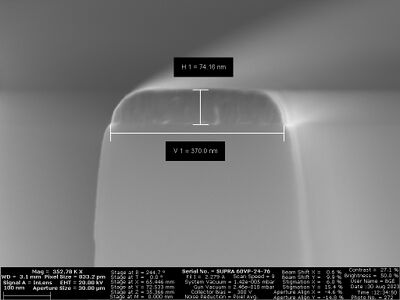

I have do some development of a SiO2 etch with resist as masking material. I have found this fairly good recipe. For now it is the standard SiO2 etch recipes but I might change the "Standard recipe" a a later time if I find a better one. If you need to etch deeper than 1 micrometer then I advise you to split the etch in several runs with O2 cleans in between (3min TDESC Clean) or else it seems like the the etch rate is going down over time.

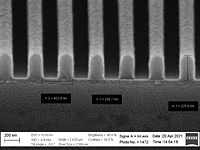

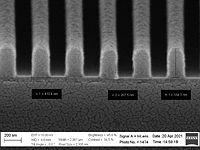

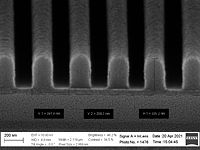

- Recipe name: SiO2_res_10, Recipe no. 10: C06445_02 coil_2500W, platen:300W, He/C4F8= 17.5, C4F8/H2=1, Pressure:8.8mTorr, C4F8:25.6sccm, He:448.7sccm, H2:25.6sccm, 3:56 min

-

0.4µ/0.2µ

Bad lithography -

0.5/0.25µ

Etch depth: 652 nm

Resist left: 456 nm -

1µ/0.5µ:

Etch depth: 855 nm

Resist left: 487 nm -

2µ/1µ:

Etch depth: 952 nm

Resist left: 487 nm -

4µ/2µ:

Etch depth: 1106 nm

Resist left: 487 nm -

0.8µ/0.2µ

Etch depth: 867 nm

Resist left: 426 nm -

1.0µ/0.25µ:

Etch depth: 893 nm

Resist left: 460 nm -

4µ/1µ:

Etch depth: 1033 nm

Resist left: 473 nm

Uniformity results with SiO2_res_10

Results with SiO2_res_10 and EM

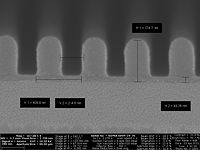

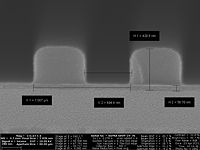

- Recipe name: SiO2_res_10, Recipe no. 10+EM coils: C06445_02 coil_2500W, platen:300W, EM:02/30A, He/C4F8= 17.5, C4F8/H2=1, Pressure:8.8mTorr, C4F8:25.6sccm, He:448.7sccm, H2:25.6sccm, 3:56 min

Using the electromagnetic coil on the recipe SiO2_res_10 gave higher etch rate on this chip that was placed in the center of a 6" wafer. The Etch profile is more angles.

- I few more test with resist mask and electromagnets can be found here: EM with resist mask

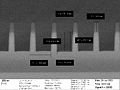

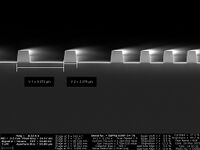

SiO2 Etch using aSi as masking material

Unless otherwise stated, all content in this section was done by Berit Herstrøm, DTU Nanolab

I was starting up development of SiO2 etch using aSi as masking material. This is on pause because the results did not look promishing on high aspect ratio structures wit DUV pattern due to large faceting on the aSi mask. I turned to Cr mask instead

The samples I use are:

- 6" Si afters with oxide (2µm),

- aSi (~300nm),

- Neg. DUV reist (~60nm barc, ~350 nm resist)

- Reticle: Danchip/Triple-D

- Dose 230 J/m2

First I need to make sure that the resist work for pattering the aSi layer is good. If the resist is not good the final etch will also not be good.

DUV optimization

Dose test with the doses (J/m2): 200, 210, 220, 230, 240, 250, 270, 280 The aim was to get good line for 400nm pitch/200nm lines

- 400nm pitch 200 nm lines

-

200 J/m2 400nm/268nm

-

210 J/m2 400nm/239nm

-

220 J/m2 400nm/208nm

-

230 J/m2 400nm/209nm

-

240 J/m2 400nm/215nm

-

250 J/m2 400nm/207nm

-

260 J/m2 400nm/188nm

-

270 J/m2 400nm/155nm

-

280 J/m2 400nm/0nm

- 1000nm pitch 500 nm lines

-

210 J/m2 1000nm/581nm

-

230 J/m2 1000nm/517nm

-

240 J/m2 1000nm/518nm

-

250 J/m2 1000nm/510nm

-

260 J/m2 1000nm/493nm

-

270 J/m2 1000nm/494nm

SiO2 etch with Cr mask

Unless otherwise stated, all content in this section was done by Berit Herstrøm, DTU Nanolab

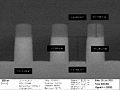

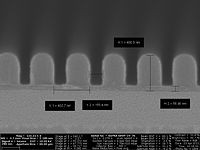

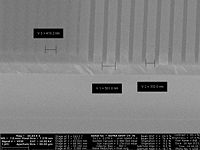

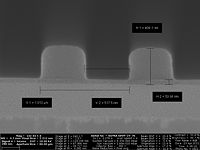

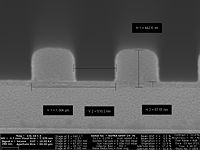

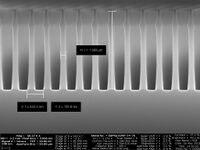

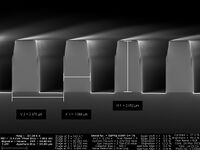

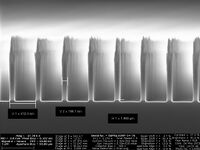

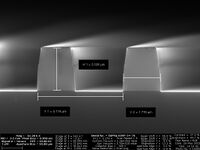

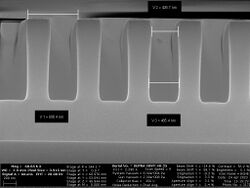

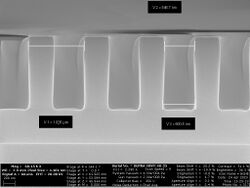

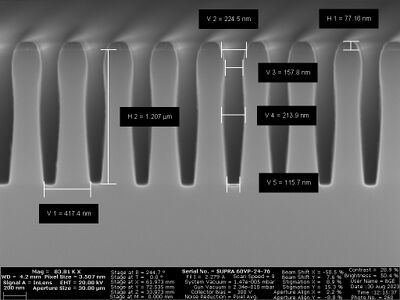

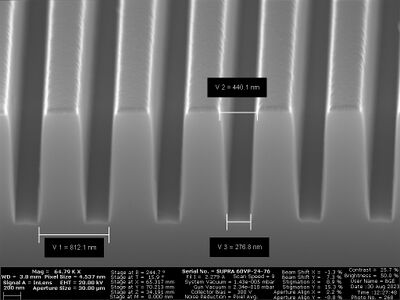

SiO2 etch with Cr mask 100 nm and with 500 nm for the resist for the Cr etch

Barc etch and Cr etch were done in ICP metal using end point detection. The sample was a full 6" wafer

- SiO2_res_10 2x5:00 min with 3 min TDESC clean in between 100 nm Cr mask, with 500 nm resist

- SiO2_res_10 5:00 min 100 nm Cr mask, with 500 nm resist, resist/Cr stripped after etch in plasma asher 35min

-

200nm/400nm

-

250nm/500nm

-

400nm/800nm

-

500nm/1000nm

-

1000nm/2000nm

-

2000nm/4000nm

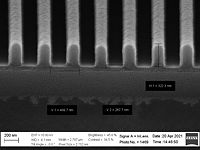

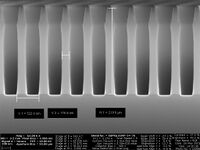

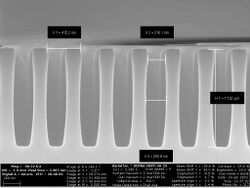

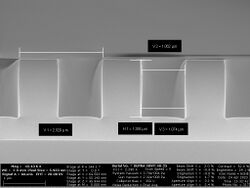

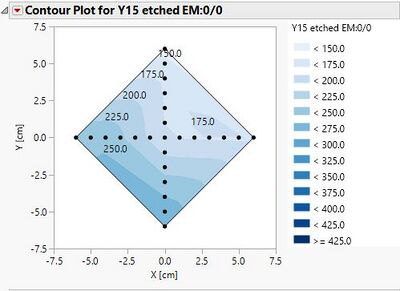

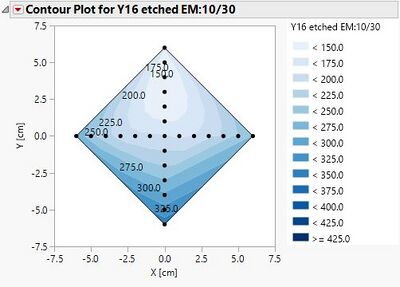

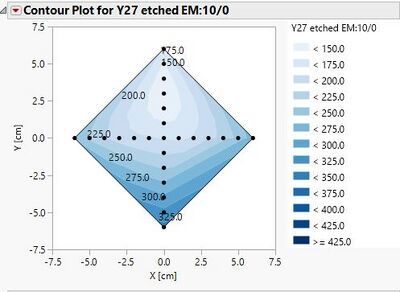

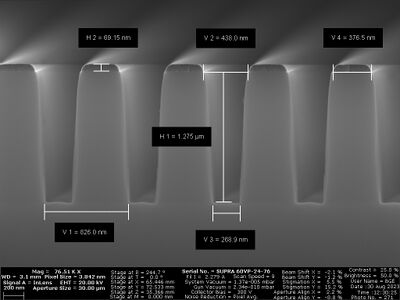

Testing with electromagnetic coils /Cr mask

Unless otherwise stated, all content in this section was done by Berit Herstrøm, DTU Nanolab

When testing with decreased platen power on the SiO2_10 standard recipe the uniformity got very bad. I then tested with the electromagnetics coil to see if that could affect the uniformity. There is an outer coil that can be varied between 0 A and 10 A and an inner coil that can be varied between 0 A and 30 A. The first tests were done on Si/SiO2(1µm) without pattern and measured on the ellipsometer.

| Parameter | Recipe name: no 10 with lower platen power |

|---|---|

| Coil Power [W] | 2500 |

| Platen Power [W] | 200 |

| Platen temperature [oC] | 20 |

| H2 flow [sccm] | 25.6 |

| C4F8 flow [sccm] | 25.6 |

| He flow [sccm] | 448.7 |

| Pressure | Fully open APC valve (8-9 mTorr) |

| Electromagnetic coils (EM) 'outer coil' / 'inner coil' | '0-10 A' / '0-30 A' |

- EM tests

-

Etch time: 2 min, Average etch rate: 100.2 nm/min, range:+-55.1%

-

Etch time: 2 min, Average etch rate: 100.5 nm/min, range:+-32.6%

-

Etch time: 2 min, Average etch rate: 100.8 nm/min, range:+-50.8%

-

Etch time: 2 min, Average etch rate: 203.8 nm/min, range:+-6.1%

-

Etch time: 2 min, Average etch rate: 186.2 nm/min, range:+-3.2%

-

Etch time: 6 min on patterned wafer with different measurement points, <100 nm Cr mask is still on, EM_2/30, Average etch rate: 207-223 nm/min depending on how much Cr mask is left, range:+-2.3%

- EM tests with Cr mask on full wafer 6 min etch