Specific Process Knowledge/Lithography/ARN8200: Difference between revisions

| (9 intermediate revisions by the same user not shown) | |||

| Line 5: | Line 5: | ||

Allresist also provides these [https://www.allresist.com/wp-content/uploads/sites/2/2020/03/SXAR-N8200-1_english_Allresist_product_information.pdf processing guidelines.] | Allresist also provides these [https://www.allresist.com/wp-content/uploads/sites/2/2020/03/SXAR-N8200-1_english_Allresist_product_information.pdf processing guidelines.] | ||

== Contrast curve == | == Contrast curve @ 100 kV (JEOL 9500) == | ||

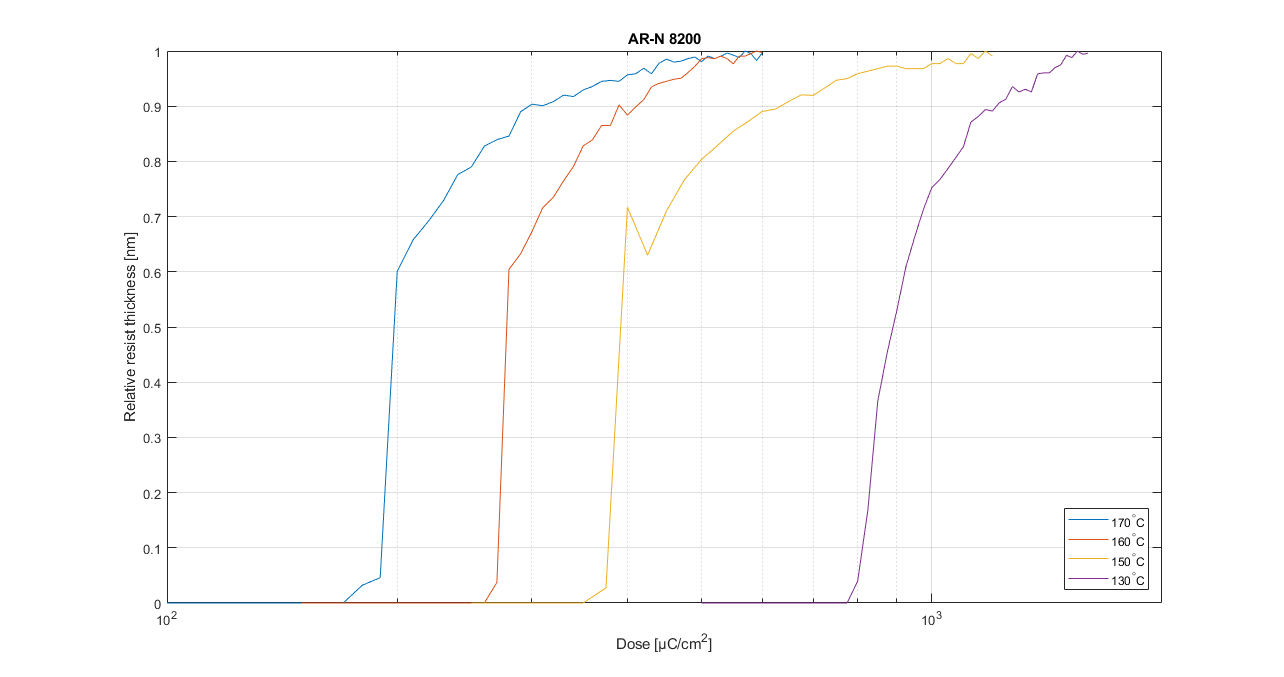

Exposure dose for AR-N 8200 is very dependent on Post Exposure Bake (PEB) temperature. A contrast curve for four different PEB processes were obtained with the following process parameters. | Exposure dose for AR-N 8200 is very dependent on Post Exposure Bake (PEB) temperature. A contrast curve for four different PEB processes were obtained with the following process parameters. | ||

{|border="1" cellspacing="0" cellpadding="3" style="text-align:left;" style="width: 95%" | {|border="1" cellspacing="0" cellpadding="3" style="text-align:left;" style="width: 95%" | ||

| Line 28: | Line 29: | ||

|- | |- | ||

|-style="background:WhiteSmoke; color:black" | |-style="background:WhiteSmoke; color:black" | ||

|AR-N8200.06 | |AR-N8200.06 | ||

|LabSpin | |LabSpin 2, 4000 rpm for 60s, softbake 10 min @ 150 degC, thickness is 110 nm | ||

| | |JBX9500, 60 nA, doses 100-1600 µC/cm2, 150 µm x 300 µm rectangles | ||

| | |Labspin 2 hotplate, 130, 150, 160 or 170 degC for 10 min | ||

| | |EBL development fumehood, 60 sec development in AR300-47:DIW (1:1), 30 sec rinse in DIW, nitrogen gun dry | ||

|- | |- | ||

|} | |} | ||

Hotplate temperatures are assumed surface temperatures based on the 0.90 correction factor in use on the hotplate. | |||

The resulting resist structure height is mapped with Dektak XTa and plotted as a contrast curve below. It is apparent that the dose and contrast is very dependent on the PEB parameters. | |||

[[file:ARN8200DoseCurve.png]] | [[file:ARN8200DoseCurve.png]] | ||

== Results at 30 kV (Raith eLINE) == | |||

A dose test is carried out with the following parameters | |||

{|border="1" cellspacing="0" cellpadding="3" style="text-align:left;" style="width: 95%" | |||

|- | |||

|- | |||

|-style="background:Black; color:White" | |||

!colspan="5"|AR-N 8200 30 kV dose test, Processed by THOPE, AUG 2022 | |||

|- | |||

|- | |||

|-style="background:WhiteSmoke; color:black" | |||

!Resist | |||

!Spin Coat | |||

!E-beam exposure | |||

!PEB | |||

!Development | |||

|- | |||

|- | |||

|-style="background:WhiteSmoke; color:black" | |||

|AR-N8200.06 | |||

|LabSpin 2, 4000 rpm for 60s, softbake 10 min @ 150 degC, thickness is 120 nm | |||

|Raith eLINE Plus, 30 kV, 60 µm aperture, 168 pA | |||

|Labspin 2 hotplate 170 degC for 10 min | |||

|EBL development fumehood, 60 sec development in AR300-47:DIW (1:1), 30 sec rinse in DIW, nitrogen gun dry | |||

|- | |||

|} | |||

Area/curved element dose: Fully insoluble dose is around 150-180 µC/cm2. | |||

Line dose: Fully insoluble dose is around 1700 pC/cm. | |||

Dot dose: Fully insoluble dose is around 0.1 pC, this gives a circular diameter of 60 nm. Diameter can be varied by increasing dose, at 0.4 pC diameter is about 100 nm and at 1.2 pC it is about 170 nm. | |||

Latest revision as of 11:42, 8 August 2022

AR-N 8200

AR-N 8200 is a negative E-beam resist from Allresist, it is also known as "Medusa 82". A product presentation from Allresist is available here AR-N8200 presentation.

Allresist also provides these processing guidelines.

Contrast curve @ 100 kV (JEOL 9500)

Exposure dose for AR-N 8200 is very dependent on Post Exposure Bake (PEB) temperature. A contrast curve for four different PEB processes were obtained with the following process parameters.

| AR-N 8200 Contrast Curve, Processed by THOPE, FEB 2022 | ||||

|---|---|---|---|---|

| Resist | Spin Coat | E-beam exposure | PEB | Development |

| AR-N8200.06 | LabSpin 2, 4000 rpm for 60s, softbake 10 min @ 150 degC, thickness is 110 nm | JBX9500, 60 nA, doses 100-1600 µC/cm2, 150 µm x 300 µm rectangles | Labspin 2 hotplate, 130, 150, 160 or 170 degC for 10 min | EBL development fumehood, 60 sec development in AR300-47:DIW (1:1), 30 sec rinse in DIW, nitrogen gun dry |

Hotplate temperatures are assumed surface temperatures based on the 0.90 correction factor in use on the hotplate.

The resulting resist structure height is mapped with Dektak XTa and plotted as a contrast curve below. It is apparent that the dose and contrast is very dependent on the PEB parameters.

Results at 30 kV (Raith eLINE)

A dose test is carried out with the following parameters

| AR-N 8200 30 kV dose test, Processed by THOPE, AUG 2022 | ||||

|---|---|---|---|---|

| Resist | Spin Coat | E-beam exposure | PEB | Development |

| AR-N8200.06 | LabSpin 2, 4000 rpm for 60s, softbake 10 min @ 150 degC, thickness is 120 nm | Raith eLINE Plus, 30 kV, 60 µm aperture, 168 pA | Labspin 2 hotplate 170 degC for 10 min | EBL development fumehood, 60 sec development in AR300-47:DIW (1:1), 30 sec rinse in DIW, nitrogen gun dry |

Area/curved element dose: Fully insoluble dose is around 150-180 µC/cm2.

Line dose: Fully insoluble dose is around 1700 pC/cm.

Dot dose: Fully insoluble dose is around 0.1 pC, this gives a circular diameter of 60 nm. Diameter can be varied by increasing dose, at 0.4 pC diameter is about 100 nm and at 1.2 pC it is about 170 nm.