Specific Process Knowledge/Thin film deposition/Deposition of TiW/Sputtering of TiW in Wordentec/Grain size and uniformity of TiW layers: Difference between revisions

Appearance

No edit summary |

|||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Thin_film_deposition/Deposition_of_TiW/Sputtering_of_TiW_in_Wordentec/Grain_size_and_uniformity_of_TiW_layers click here]''' | '''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Thin_film_deposition/Deposition_of_TiW/Sputtering_of_TiW_in_Wordentec/Grain_size_and_uniformity_of_TiW_layers click here]''' | ||

==Grains | ==Grains and uniformity of a sputtered TiW film== | ||

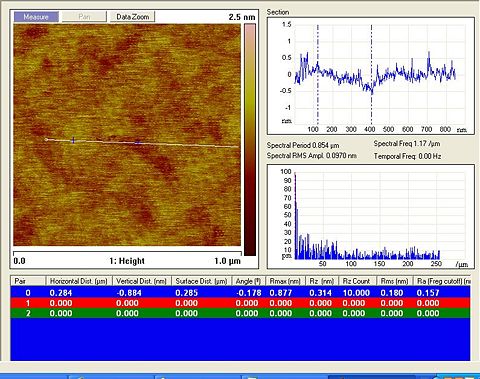

TiW films were deposited by sputtering in the Wordentec. AFM pictures show how the surface roughness is dependent on the process parameters. | TiW films were deposited by sputtering in the Wordentec. AFM pictures show how the surface roughness is dependent on the process parameters. | ||

Revision as of 11:38, 19 March 2020

Feedback to this page: click here

Grains and uniformity of a sputtered TiW film

TiW films were deposited by sputtering in the Wordentec. AFM pictures show how the surface roughness is dependent on the process parameters.

For the sputter process, the power and argon pressure can be set to different values. Depending on the process parameters, the deposited layers will have different characteristics: the roughness, grain size and uniformity may be different.

Power 150 W, pressure 1*10-3 mbar

With use of the settings 150W and 1*10-3 mbar, a surface with low roughness is deposited.

Measurement done September 2008, KNIL.