Specific Process Knowledge/Thin film deposition/Deposition of Silicon Oxide/Deposition of SiO2 in E-Beam Evaporator Temescal-2

Feedback to this page: click here

This page is written by Evgeniy Shkondin @DTU Nanolab if nothing else is stated.

All images and photos on this page belongs to DTU Nanolab.

The fabrication and characterization described below were conducted in 2023 by Patama Pholprasit and Evgeniy Shkondin, DTU Nanolab.

Evaporation of SiO2 in Temescal-2

This page describes e-beam evaporation method of SiO2 in 10-pocket e-beam evaporator. E-Beam Evaporator (10-pockets) - Temescal-2 allows deposition with elevated temperature and O2 gas bleed. This is ideal conditions of evaporation of oxides such as SiO2, TiO2, Al2O3 and ITO.

We highly recommend adding 5% O2 and maintaining a temperature of at least 200°C to achieve high-quality stoichiometric SiO2 films. Under these conditions, you can expect to produce optical films with smooth surfaces, excellent amorphous properties, and strong adhesion.

After prolonged usage, the responsible team must replace the target once it becomes black, as this indicates that the SiO2 pellets are starting to lose oxygen.

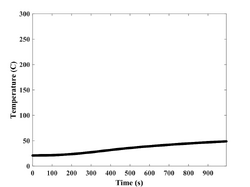

In these tests we evaporated SiO2 with 5% O2 and with and without temperature of 200 °C. Please be aware that evaporations requiring elevated temperatures should only be conducted using the 8-inch holder (as shown in the photo) with an adaptor tailored to the wafer size. Various accessories enable the use of the 8-inch wafer holder with a range of samples, from 8-inch wafers to small chips. NEVER attempt to use HULA with high-temperature processes, as they can potentially damage the magnetic components of HULA. If you are unsure, please consult the tool responsible for guidance.

SiO2 evaporates from source 9 or 10 in Temescal-2 using a graphite liner. Please write to metal@nanolab.dtu.dk at least a week in advance if you wish to request a material in a liner in pocket 9 or 10.

Uniformity across 150 mm wafer

Results have been obtained for <100> 150 mm Si wafers with native oxide, based on ellipsometry study.

| Temperature (°C) / Thickness setpoint | Deposition rate (nm/s) | Tooling Factor | O2 Gas (%) | Average thickness (nm) | Minimum thickness (nm) | Maximum thickness (nm) | Standard deviation | Uniformity (%) |

|---|---|---|---|---|---|---|---|---|

| 200°C / 80 nm | 1 | 79 | 5 | 78.95 | 72.96 | 83.44 | 3.1268 | 6.6365 |

| room temperature / 80 nm | 1 | 79 | 5 | 85.43 | 80.36 | 89.02 | 2.5510 | 5.0737 |

Optical functions

Results have been obtained for <100> 150 mm Si wafers with native oxide, based on ellipsometry study. Sellmeier model has been implemented for refractive index fitting.