Specific Process Knowledge/Back-end processing/Polymer Injection Molder/AfterPressure

After (holding) pressure

After injection it is generally necessary to maintain the injection pressure for a certain time. The time required will depend on processing parameters (especially mold and melt temperatures), but generally it is desired to maintain a pressure for long enough time for the gate to have solidified. Too short duration or too low after pressure can cause the polymer to flow backwards (out of the cavity) or that the sample gets an uneven surface (sink marks) because the sample shrinks as the polymer cools down. On the other hand too high after pressure or time can cause high levels of stress in the sample (due to excessive packing of polymer) and at some point increasing after pressure and time will cause the sample to get stuck in the mold, masking it very hard to remove.

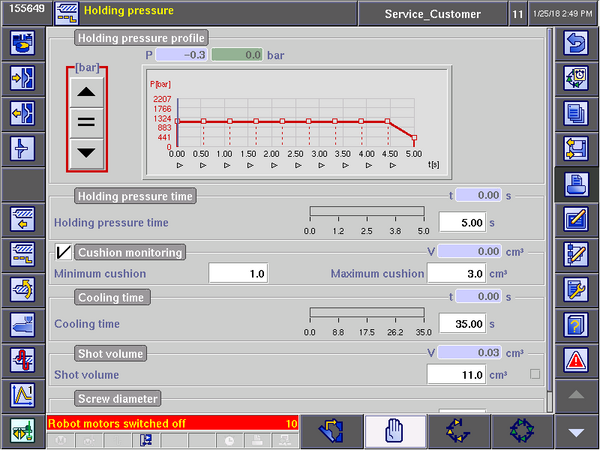

The after/holding pressure settings are found on the 'Holding pressure' screen:

- Holding pressure profile: Holding pressures can be set as a constant pressure (by pressing the '=' next to the curve and entering a value) or as a pressure that varies with holding time (by pressing the graph areas and editing the points). It is preferable to let the holding pressure gradually taper off as shown here to avoid very abrupt changes in pressure. Just letting go from e.g. 1000 bar to 0 bar causes the screw to fly back violently and should be avoided.

- Holding pressure time: The holding time is entered here. The time axis in the graph will update automatically when the value is changed.

- Cushion monitoring: The cushion is the amount of polymer left in the barrel (heating cylinder) after injection. A small amount must be left in order to be able to maintain a holding pressure. It is recommended to keep the cushion around the center of the interval (i.e. ~1,5 cm3). If the cushion is too small the shot volume should be increased and if the cushion is too large the shot volume should be decreased accordingly. Please note that the cushion is pressure dependent. Increasing the holding pressure will decrease the cushion (because the higher the holding pressure the higher compression of the polymer).

- Shot volume: If the cushion is too small or too large, adjustments of the shot volume can be quickly made here, as described above. All other settings relevant for dosing (plasticizing) are found on the Plasticizing screen.