LabAdviser/Technology Research/Fabrication of Hyperbolic Metamaterials using Atomic Layer Deposition/EMT Procces flow

Feedback to this page: click here

This page is written by Evgeniy Shkondin @DTU Nanolab if nothing else is stated.

All images and photos on this page belongs to DTU Nanolab and DTU Electro (previous DTU Fotonik).

The fabrication and characterization described below were conducted in 2013-2016 by Evgeniy Shkondin, DTU Nanolab.

Procces flow description

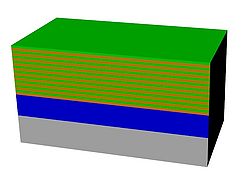

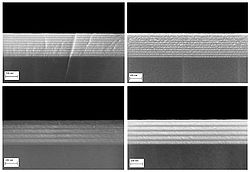

The substrates for the samples were fabricated by depositing 1 μm of Si3N4 (the resonator layer) on 100 mm silicon < 100 > wafers using low-pressure chemical vapor deposition. The process was carried out at 780C with ammonia (NH3) and dichlorosilane (SiH2Cl2) as reactive gases. Thickness and refractive index of the deposited silicon nitride was measured and confirmed using spectroscopic ellipsometry. The deposited Si3N4 film was carefully analyzed for existence of cracks, particles and other defects using dark field optical microscopy. The best-quality wafer with Si3N4 was selected and cleaved in pieces, which were used as substrates for the deposition of Al2O3/TiO2 multilayers. Before inserting each substrate into the ALD reactor, it was placed on a Si carrier wafer. Therefore the Al2O3/TiO2 multilayers were grown not only on the Si3N4 layer but also on the dummy carrier wafer. After the ALD process was completed, the dummy was cleaved and its cross-section was characterized using scanning electron microscopy (SEM). The SEM images reveal high-quality homogeneous, conformal coatings, as seen in the examples in Figs 1. Such a method of deposited multilayers characterization turned out to be more feasible than the direct SEM characterization of multilayers on Si3N4, since the latter suffers from issues related to charge accumulation on the silicon nitride.

Process flow

Description of process flow.

| Step | Description | LabAdviser link | Image showing the step | |

|---|---|---|---|---|

| 1.1 | Plasma surface treatment | To ensure clean surface, the 100 mm Si wafer is treated by O2/N2 plasma. | Plasma Asher 2 | |

| 1.2 | Deposition of 1 µm Si3N4 layer | Deposition carries 7 times in order to get 1 µm thick film | 6" LPCVD nitride furnace. | |

| 1.3 | Surface investigation using optical microscopy in dark field mode | The best quility wafer selects and cleaves in four pieces. | Optical Microscopy. | |

| 1.4 | TiO2/Al3O3 multilayers deposition using Atomic Layer Deposition | Deposition using recipies EMA01, EMA02, EMA03 and EMA04. | ALD Picosun R200, EMA01-04 Recipes description and performance: Multilayrs recipes and their performance . | |

| 1.5 | Scanning Electron Microscopy inspection | By cleaving the sample it is possible to inspect depositet ALD layers uniformity in cross-sectional mode | ||

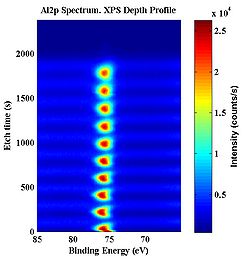

| 1.6 | XPS inspection for elemental trace analysis | XPS can be used in depth profile mode. Ar+ ions erodes the surface of multilayers, allowing the inspection of each layer. | Equipment used: XPS K-Alpha. Results of depth profiling presented: XPS results . | |