LabAdviser/314/Microscopy 314-307/Technique/X-ray spectroscopy/EDS-SEM

Feedback to this page: click here

(content by Berit Wenzell, April 2020)

EDS-SEM Quick Guide

- 1) Link the working distance (WD) and bring Z-height to 10mm WD

- 2) Launch Aztec and save the file on the shared drive

- 3) Insert EDS detector

- 4) Select high-voltage (HV)

- Select an accelerating voltage that is 2-3x higher than the energy characteristic X-ray you want to generate from the element with the highest atomic number (Z)

- Could be 15kV for silicates…, 20kV for metal

- 5) Select operating mode

-

- Point & ID: acquire image, select a point or area of interest for analysis

- Mapping: elemental distribution in region of interest

- Optimization: calibrate if needed – see below if needed.

- 6) Select process time

-

- High number – good energy resolution

- Low number – good counting statistic

- Could be 5 for Point & ID 2 for Mapping

- 7) Bring the dead time to 30 – 50 %

- Change the dead time by changing the beam current (spot or aperture)

- The beam current cannot be higher than what the sample allows, to avoid charging and beam damage. To avoid beam induced effects, accept a low dead time and count for a longer time.

- If the dead time is 100% turn off the CCD.

- 8) Aztec software

- Use the software to acquire data and process data.

- Fill out the settings from left to right. Acquire image, spectrum. Process the data.

- 9) After use, retract the detector

EDS-SEM Quick Guide - Explained

1) Link the working distance (WD) and bring Z-height to 10 mm WD

Focus on the surface of the sample at 2000x magnification or higher to find the true working distance (WD) at a given stage height and given sample height. Press the button with the red question mark to links the working distance with the movement of the sample stage along the z-axis. The z-coordinate switches between showing the distance of how much the stage has moved up and the working distance.

Bring the stage to a 10mm working distance, by setting the z-coordinate to 10mm.

Different microscopes have different optimal setting for the EDS.

Too short WD: the pole piece or backscatter detector might shadow for the X-rays.

Too long WD: the matrix correction used for quantification and correction for the internal Si fluorescence peak from the detector might be wrong.

If your sample is not flat: focus on the highest point to avoid damaging the pole piece or the backscatter detector. However, you no longer remain in a 10mm working distance when moving away from the linked coordinate.

Double click on the Aztec button to launch the Aztec software. ![]()

You will be prompted to either open an existing project or to create a new project. Save the project as an “Aztec project” by selecting “file” and save as a project. Browse the file pathway and find the shared folder. The project files will automatically be saved into this folder.

Important: Do not use your personal login on the support-pc, otherwise the EDS detector will lose connection to the microscope-pc. After acquiring data, the Aztec software can be found on different computers in 314 and 307, which means microscope time is not needed to process the data.

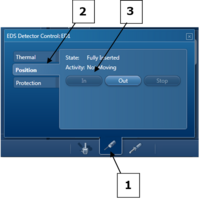

3) Insert EDS detector

Setup the EDS detector by using the control window found at the bottom right corner of the screen.

- 1) Select the button that looks like an EDS detector

- 2) Go to the “Position” tab/window

- 3) Insert EDS detector into the chamber, by pressing the “In” button

The EDS detector moves into the chamber

- 4) Go to the “thermal” tab/window

- 5) Switch EDS from “standby” into “operating” mode

- 6) Wait until the detector is ready

4) Choose accelerating voltage (HV)

To generate X-ray photons an ionization event is required. The minimum energy to produce an ionization event has a critical ionization energy (Ec). The critical ionization energy is different for each shell and subshell. Inner shell electrons (K) have highest Ec. If the incident beam energy has a high enough energy to excite K shell electrons, it can excite X-rays from all the other shells. Select the accelerating voltage 2-3x higher than the energy of the X-ray, you want to generate. In other terms, the overvoltage (U) should be around 2.4 to have the optimal accelerating voltage/electron energy of the primary beam/energy of electrons leaving the gun (E0).

Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle U=E_0/E_C, \qquad E_C=\text{critical excitation voltage}}

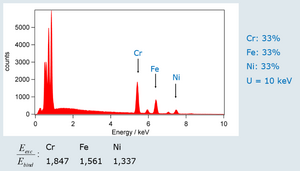

Example: Analysis of a sample, where the element with highest energy that need to be analyzed is:

FeKα: 6.4 keV

Select acceleration voltage: Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle hV= 2.6 \times 6.4 \approx 15 kV}

Without sufficient overvoltage, X-ray production is drastically reduced.

Too high accelerating voltage: the size of the interaction volume will increase. That means huge correction for absorption, especially for the low energy lines and fluorescence for high energy, leads to a big error. For high accelerating voltage you need to consider the risk of beam damage.

Too low accelerating voltage: you might not have enough energy to kick out an electron from the inner shells. In Figure 1, the overvoltage for Ni is very low, resulting in a very small peak. The counting statistic becomes very poor for Ni at that low HV, even though Ni is present in very high concentration.

When analyzing small features, the beam voltage needs to be reduced to avoid generation of X-rays from surrounding material. However, at low kV only low energy lines are available for analysis. When working at 20 kV, the separation of widely spaced K lines of Cr, Fe and Ni, will not be affected much by a few eV variations in resolution. However, when working at 5 kV the identification relies on L lines, which are very close in energy. The primary-beam electrons lose energy and change direction due to inelastic scattering within the sample. Some of the lost energy is converted to X-rays, which have a range of energies, from ~0 eV up to E0 (electron energy of the primary beam). Bremsstrahlung X-rays cannot have energies greater than the energy of the electrons in the primary beam so this energy forms the upper energy limit of the X-ray spectrum and is known as the Duane-Hunt limit. That means if you are running at 20kV the background/bremsstrahlung will fade out at 20keV. If the sample is charging, the electrons from the gun are decelerated. The electrons hit the surface of the sample at a lower energy than E0. This means, that matrix correction, background etc, will be wrong.

5) Select operating mode

From the EDS dropdown menu select 1 out of 4 different scan options available.

Point & ID

Quickly analysis composition at a specific point or across a region of interest. Both qualitative, chemical identification, quantitative normalized or unnormalized analysis are possible with or without standards.

Linescan

Determines the concentration of elements across a user-defined line.

Mapping

The beam scans over a selected area to find the elemental distribution in the region of interest.

Optimizing

Two calibration methods are available:

Energy Calibration: For accurate identification of peaks (qualitative and normalized quantitative analyses) Energy Calibration is needed. Energy Calibration measures the shift in the position of the spectral peaks and resolution of the system. As the system has very stable electronics, the system only needs to be calibrated once in several months, provided the environmental temperature of the laboratory is fairly stable. A change of a few degrees in the environmental temperature can cause a small shift in the position of peaks. The Energy Calibration method is performed for representative Process times, available energy ranges and number of channels in one operation. This means, if changing any of the settings soon after Energy Calibration was performed, the system does not need to be re-calibrated. For how to perform Energy Calibration, see manual.

Beam Measurement: If you are an expert user, needing more than relative concentrations and require accurate quantitative analysis with un-normalized quantitative analysis results, Beam Measurement is needed. Any change in the microscope settings such as accelerating voltage or lens control will lead to a change in the beam current. Under these circumstances the Beam Measurement method must be performed before accurate quantitative analysis.

- Note the Beam Measurement method does not need to be performed if only interested in: Qualitative Analysis and Normalized Quantitative Analysis. For how to perform Beam Measurement, see manual.