Specific Process Knowledge/Thin film deposition/Deposition of Chromium/Deposition of Chromium

Feedback to this page: click here

Uniformity of Cr layers

The result here from Katharina Nilson @ Danchip (August 2008)

Cr have been deposited with both E-beam evaporation and sputtering deposition to examine if there are differences in the uniformity of the Cr layers.

Experimental

Cr depositions have been done directly on unprocessed Si wafers, all depositions has been done in Wordentec. The deposited layers have therafter been examined with AFM.

Results

There are differences in uniformity and grain size, for the various deposition methods. For the sputtering processes there are large differences depending on the settings during the process, i. e. Ar pressure and effect.

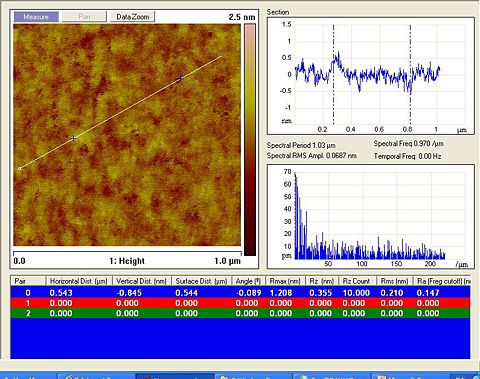

E-beam process

The Cr layer deposited with e-beam in the Wordentec has a low roughness, and are uniform. The deposition rate has been 10 Å/s.

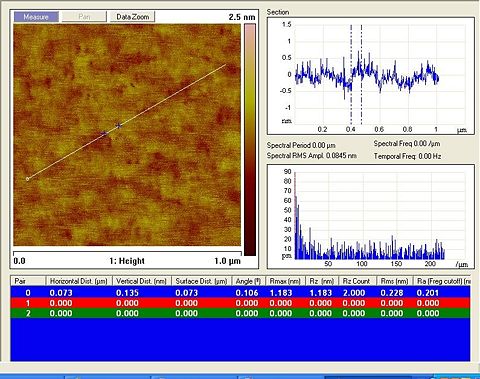

Sputting process

In the Wordentec the Ar pressure can be set to between Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle 1*10^{-3}} and Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle 5*10^{-2}} mbar during the process, and the effect may be varied between 150 and 400 W. ( Here are AFM pictures of sputtered layers, deposited with different settings, shown.

Effect 150 W, pressure Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle 1*10^{-3}}

mbar

With these settings the deposited layers are uniform and has a low roughness.

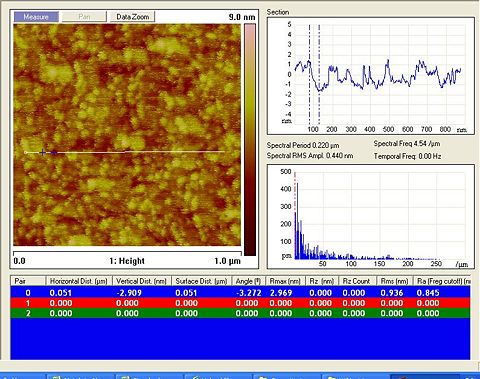

Effect 405 W, pressure Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle 1*10^{-3}}

mbar

405 W and Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle 1*10^{-3}} mbar Ar pressure results in a surface with large roughness. The surface grais are comparably small (most about 30 nm in diameter, and almost all below 50 nm).

Effect 405 W, pressure Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle 4*10^{-3}}

mbar

These settings give a rough surface, with larger grains (up to 100nm in diameter).

Conclusions

The roughness of Cr layers is very different for the sputter depositions with different setting. The layer with lowest roughness is achived by using 150 W and Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle 1*10^{-3}} mbar argon pressure. A layer with similar rouhgness is also the result of an e-beam process (Wordentec). However, the use of sputtering deposition will give a better step coverage then the e-beam process.