Specific Process Knowledge/Back-end processing/Polymer Injection Molder/AfterPressure

After (holding) pressure

After injection it is generally necessary to maintain the injection pressure for a certain time. The time required will depend on processing parameters (especially mold and melt temperatures) but generally it is desired to maintain a pressure for long enough time for the gate to have solidified. Too short duration or too low after pressure can cause the polymer to flow backwards (out of the cavity) or that the sample gets an uneven surface (sink marks) because the sample shrinks as the polymer cools down. On the other hand too high after pressure or time can cause high levels of stress in the sample (due to excessive packing of polymer) and at some point increasing after pressure and time will cause the sample to get stuck in the mold, masking it very hard to remove.

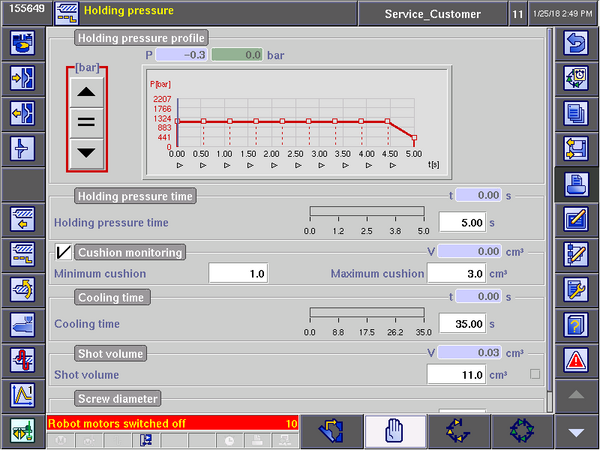

The after/holding pressure settings are found on the 'Holding pressyre' screen:

- Volume-dependent switchover: A certain volume of polymer is injected. Note that the volume entered (3,2 cm3 in this example) is not the volume injected, but the amount of polymer left after injection! Also note that changes in shot volume (the amount of polymer in the heating cylinder before injection) will also change injected volume unless the switch-over point is adjusted accordingly. Volume dependent switchover is particularly well suited for developing new injection molding processes (so you can gradually find the point where the cavity is almost filled and then work from there) or if you already know the exact volume of polymer required.

- Time-dependent switchover: After a certain amount of time, injection is considered complete. Not used very often because it offers very little control over both injection volume and pressure.

- Injection pressure-dependent switchover: Polymer is injected until a certain pressure is reached. Please note that the pressure in question is measured in the injection unit (heating cylinder). The pressure inside the cavity is not known. Special molds with an integrated pressure transducer is required to determine cavity pressures (very interesting, but unfortunately not available at DTU Danchip). This switchover type is very easy to use and is not influenced by e.g. changes in shot volume. The selected switchover pressure (in this example 800 bar) is critical for replication. Very low switchover pressures can result in bad replication or even incomplete filling while too high pressure can cause the sample to stick so well to the shim, that it gets very difficult to demold.

- External switchover: Injection continues until a signal is received from an external device (e.g. an external pressure transducer). Can not be used, since no external external device is available.

- Parallel switchover: Injection is defined by a combination of parameters. Has never been used until now.