Specific Process Knowledge/Etch/DRIE-Pegasus/nanoetch/nano142

Feedback to this page: click here

The nano1.42 recipe

Unless otherwise stated, all content on this page was created by Jonas Michael-Lindhard, DTU Nanolab

| Recipe | Gas | C4F8 75 sccm, SF6 38 sccm |

|---|---|---|

| Pressure | 4 mTorr, Strike 3 secs @ 15 mTorr | |

| Power | 800 W CP, 40 W PP | |

| Temperature | -20 degs | |

| Hardware | 100 mm Spacers | |

| Time | 120 secs | |

| Conditions | Run ID | 2017 |

| Conditioning | Sequence: Oxygen clean, MU tests, processes, no oxygen between runs | |

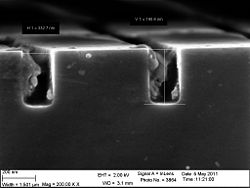

| Mask | 211 nm zep etched down to 82 nm |

- The results of the nano1.42 recipe

-

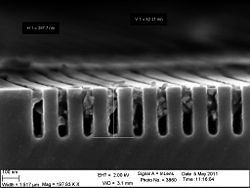

The 30 nm trenches

-

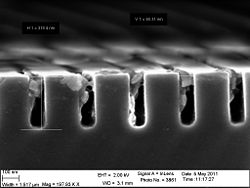

The 60 nm trenches

-

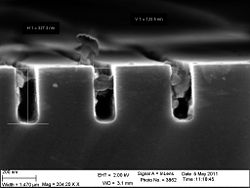

The 90 nm trenches

-

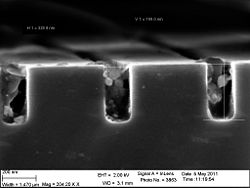

The 120 nm trenches

-

The 150 nm trenches

| Nominal trench line width | ' | 30 | 60 | 90 | 120 | 150 | Average | Std. dev. |

| Etch rates | nm/min | 148 | 158 | 164 | 167 | 166 | 160 | 8 |

| Sidewall angle | degs | 90 | 90 | 90 | 90 | 90 | 90 | 0 |

| CD loss | nm/edge | 7 | -7 | -7 | -28 | -28 | -13 | 15 |

| CD loss foot | nm/edge | 12 | 5 | 6 | -15 | -1 | 1 | 10 |

| Bowing | -1 | 1 | -2 | -5 | -7 | -3 | 3 | |

| Bottom curvature | -46 | -30 | -29 | -31 | -27 | -32 | 8 | |

| zep | nm/min | 65 | ||||||

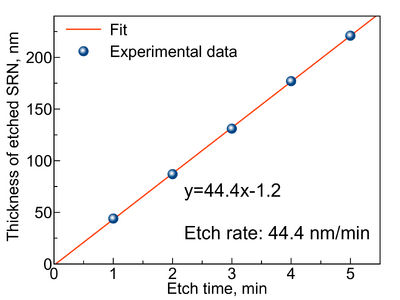

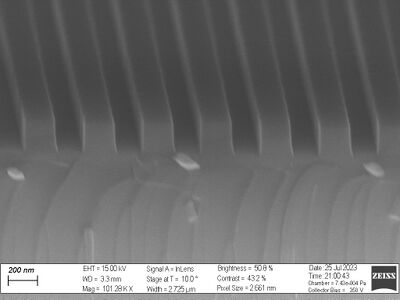

Etching SRN (Silicon Rich Nitride) with nano1.42

This test has been done by Leonid Beliaev

- 274nm SRN by LPCVD ("6 inch LS" recipe)

- Substrate: Si/SiO2(1100nm)

- DUV-lithography: KRF M230Y resist 360 nm, Barc 65 nm, exposure dose 220J/m2

- Pattern: Grating with period 400 nm and grating bar width of

- Barc etch in Pegasus 1 at -19 deg, 40s

- Nano 1.42 at -19 deg, 5 min