Specific Process Knowledge/Back-end processing/Polymer Injection Molder/Process: Difference between revisions

No edit summary |

|||

| Line 1: | Line 1: | ||

== Process overview == | == Process overview == | ||

Once a process is running satisfactory, the machine also has tool that can be used for monitoring a running process. | Once a process is running satisfactory, the machine also has tool that can be used for monitoring a running process. These tools can be help to ensure desired sample quality and reproducibility. | ||

[[File:13- | [[File:13-cycletime.png|600px|thumb|left|The 'Cycle time' screen provides an overview of the entire injection molding cycle.]] | ||

<br><br> | <br><br> | ||

*'''Advance profile''': This parameter controls the speed profile as the tower moves forward to press the nozzle against the mold inlet port. The default settings work fine for most applications. | *'''Advance profile''': This parameter controls the speed profile as the tower moves forward to press the nozzle against the mold inlet port. The default settings work fine for most applications. | ||

| Line 13: | Line 13: | ||

Scrolling down will reveal a few more important settings regarding nozzle control: | Scrolling down will reveal a few more important settings regarding nozzle control: | ||

<br> | <br> | ||

[[File: | [[File:14-micrograph.png|600px|thumb|left|Scrolling down on the 'Tower' screen reveals additional nozzle settings.]] | ||

<br><br><br><br><br> | <br><br><br><br><br> | ||

*'''Force build-up time''': This setting defines how long time the machine has to build up the nozzle contact force. A value of 0,2-0,5 sec works fine for most applications | *'''Force build-up time''': This setting defines how long time the machine has to build up the nozzle contact force. A value of 0,2-0,5 sec works fine for most applications | ||

| Line 20: | Line 20: | ||

<br> | <br> | ||

*'''Delay time retraction''': In some cases it may be desirable to maintain the inlet port at high temperature after injection and holdin/after pressure. In this case a delay can be entered here (usually 5 - 10 seconds is fine). Keep in mind that if the sum of 'Plasticizing delay time' described earlier and the 'Delay time retraction' on this page exceeds the cooling time, this will cause a delay in the injection molding cycle (thus increasing the effective cooling time). | *'''Delay time retraction''': In some cases it may be desirable to maintain the inlet port at high temperature after injection and holdin/after pressure. In this case a delay can be entered here (usually 5 - 10 seconds is fine). Keep in mind that if the sum of 'Plasticizing delay time' described earlier and the 'Delay time retraction' on this page exceeds the cooling time, this will cause a delay in the injection molding cycle (thus increasing the effective cooling time). | ||

<br><br><br><br><br><br><br><br><br><br><br><br><br> | |||

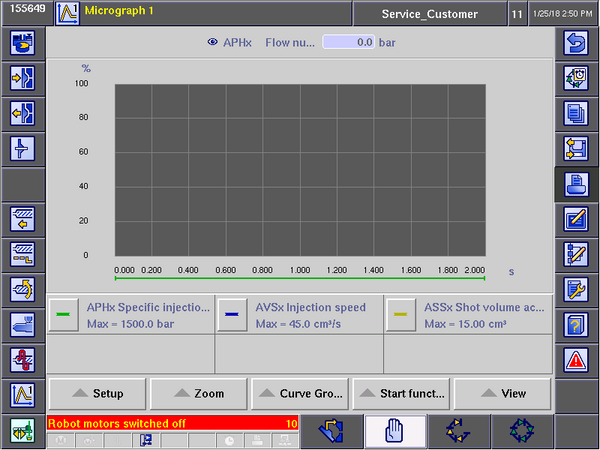

There are also other possibilities for documenting and monitoring injection molding processes. | |||

Revision as of 11:35, 12 February 2018

Process overview

Once a process is running satisfactory, the machine also has tool that can be used for monitoring a running process. These tools can be help to ensure desired sample quality and reproducibility.

- Advance profile: This parameter controls the speed profile as the tower moves forward to press the nozzle against the mold inlet port. The default settings work fine for most applications.

- Retract profile: This parameter controls the speed profile as the tower moves backwards and retracts the nozzle from the mold inlet port. Again, the default settings will work fine for most applications.

- Nozzle stroke: This setting controls how far the nozzle moves back between shots. Usually a value between 40 - 100 mm will work fine. Usually it is only for for highly optimized industrial processes that it makes sense to optimize this parameter (temperature of the inlet port versus time spent on moving the nozzle back and forth).

Scrolling down will reveal a few more important settings regarding nozzle control:

- Force build-up time: This setting defines how long time the machine has to build up the nozzle contact force. A value of 0,2-0,5 sec works fine for most applications

- Contact force: This parameter defines how hard the nozzle presses against the inlet port during injection and after/holding pressure. Please do not increase this value above 15 kN without contacting DTU Danchip as this may damage the nozzle tip or the mold inlet port! For polymers that undergo significant shear thinning (such as PP and PE) contact forces around 14 kN can be required (depends on injection speed) while lower contact forces (10 - 12 kN) will be sufficient for most other polymers.

- Delay time retraction: In some cases it may be desirable to maintain the inlet port at high temperature after injection and holdin/after pressure. In this case a delay can be entered here (usually 5 - 10 seconds is fine). Keep in mind that if the sum of 'Plasticizing delay time' described earlier and the 'Delay time retraction' on this page exceeds the cooling time, this will cause a delay in the injection molding cycle (thus increasing the effective cooling time).

There are also other possibilities for documenting and monitoring injection molding processes.