Specific Process Knowledge/Etch/DRIE-Pegasus/nanoetch/nano14: Difference between revisions

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:labadviser@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php/Specific_Process_Knowledge/Etch/DRIE-Pegasus/nanoetch/nano14 click here]''' | '''Feedback to this page''': '''[mailto:labadviser@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php/Specific_Process_Knowledge/Etch/DRIE-Pegasus/nanoetch/nano14 click here]''' | ||

<!--Checked for updates on 3/2-2016 - ok/jmli --> | |||

Revision as of 15:25, 3 February 2016

Feedback to this page: click here

The nano1.4 recipe

| Recipe | Gas | C4F8 75 sccm, SF6 38 sccm |

|---|---|---|

| Pressure | 4 mTorr, Strike 3 secs @ 15 mTorr | |

| Power | 800 W CP, 50 W PP | |

| Temperature | -20 degs | |

| Hardware | 100 mm Spacers | |

| Time | 120 secs | |

| Conditions | Run ID | 2000 |

| Conditioning | Sequence: Oxygen clean, MU tests, processes, no oxygen between runs | |

| Mask | 211 nm zep etched down to 77 nm |

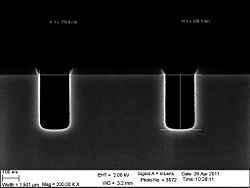

- The results of the nano1.4 recipe

-

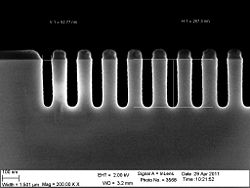

The 30 nm trenches

-

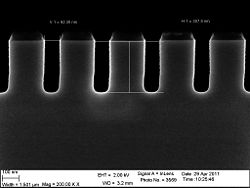

The 60 nm trenches

-

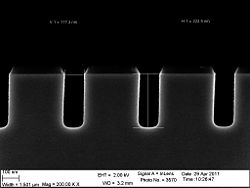

The 90 nm trenches

-

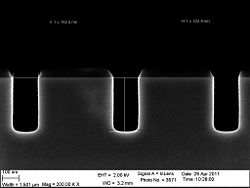

The 120 nm trenches

-

The 150 nm trenches

| Nominal trench line width | ' | 30 | 60 | 90 | 120 | 150 | Average | Std. dev. |

| Etch rates | nm/min | 168 | 182 | 185 | 189 | 191 | 183 | 9 |

| Sidewall angle | degs | 91 | 91 | 91 | 91 | 90 | 91 | 0 |

| CD loss | nm/edge | 7 | -3 | -3 | -25 | -26 | -10 | 15 |

| CD loss foot | nm/edge | 12 | 9 | 10 | -11 | 1 | 4 | 9 |

| Bowing | 9 | 6 | 4 | 5 | 7 | 6 | 2 | |

| Bottom curvature | -47 | -34 | -34 | -26 | -19 | -32 | 10 | |

| zep | nm/min | 67 | ||||||