Specific Process Knowledge/Lithography/Espacer: Difference between revisions

No edit summary |

No edit summary |

||

| Line 83: | Line 83: | ||

|-style="background:WhiteSmoke; text-align:center; color:black" | |-style="background:WhiteSmoke; text-align:center; color:black" | ||

|Zeiss SEM supra 60VP, D-2 | |Characterization | ||

|colspan="2"|Zeiss SEM supra 60VP, D-2 | |||

|- | |||

|-style="background:WhiteSmoke; text-align:center; color:black" | |||

|230 muC/cm2 | |||

| | | | ||

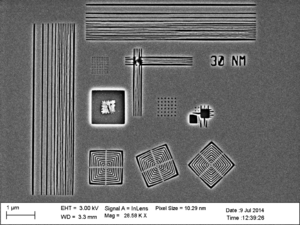

| | | [[File:EspacerBorofloat30nmBasedose.png|300px]] | ||

|- | |- | ||

Revision as of 11:37, 10 July 2014

We have Espacer in stock and approved for use in the cleanroom. You can find a guideline for a process flow here: Process_Flow_ZEP_ESPACER.docx. Technical information of Espacer can be found here: Espacer_300_Technical_Info.pdf, Espacer_catalog.pdf.

Please contact Lithography if you wish to test this material.

| Process | No ESPACER | ESPACER |

|---|---|---|

| Resist | AR-P 6200/2 AllResist E-beam resist | |

| Spin Coat | 1 min @ 4000 rpm, softbake 2 min @ 150 degC, thickness ~140nm | |

| ESPACER | 1 min @ 2000 rpm (no softbake), Manual Spinner 1 (Laurell) | |

| E-beam exposure | 2 nA, aperture 5, dose 150-310 muC/cm2, SHOT A,10 | |

| Rinse | Rinsed with hand shower in fumehood, dried with N2 gun | |

| Developing | SX-AR 600-54/6 60 sec, 60 sec IPA rinse | |

| Characterization | Nikon ECLIPSE optical microscope, E-5 | |

| All doses |

|

|

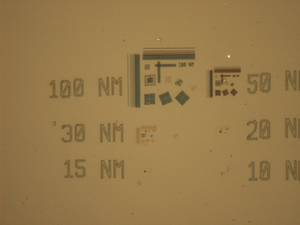

| 230 muC/cm2 |

|

|

| 219 muC/cm2 |

|

|

| Sputter Coated | <10nm Pt at DTU CEN | |

| Characterization | Zeiss SEM supra 60VP, D-2 | |

| 230 muC/cm2 |

| |