LabAdviser/314/Preparation 314-307/Solid-matter: Difference between revisions

No edit summary |

No edit summary |

||

| (27 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/LabAdviser/314/Preparation_314-307/Solid-matter click here]''' | |||

''This section is written by DTU Nanolab internal if nothing else is stated.'' | |||

[[Category:314]] | |||

[[Category:314-Preparation]] | |||

Mechanical preparation equipment is available for experience users, who know how to use the equipment. Access to the preparation lab is needed. We do not provide training on the equipment. | |||

= Cutting = | = Cutting = | ||

| Line 12: | Line 21: | ||

== Well Precision Diamond Wire Saw == | == Well Precision Diamond Wire Saw == | ||

[ | [https://www.well-dws.com/wp-content/uploads/2020/02/Flyer_A4_3500_E-2.pdf Brochure] | ||

[[File:IMG_3665.JPG|200px|left|thumb|Location Building 307, Prep Lab 109]]<br /> | [[File:IMG_3665.JPG|200px|left|thumb|Location Building 307, Prep Lab 109]]<br /> | ||

| Line 18: | Line 27: | ||

<br clear="all" /> | <br clear="all" /> | ||

== Ultrasonic cutter == | |||

[https://labmanager.dtu.dk/view_binary.php?class=MiscDocument&id=15&name=Manual+-+ULTRASONIC+DISK+CUTTER+MODEL+170.pdf Manual] ''- requires login'' | |||

[[File:Ultrasonic_Cutter.jpg|200px|left|thumb|Location Building 307, Prep Lab 109]].<br /> | |||

<br clear="all" /> | |||

= Grinding/Polishing = | = Grinding/Polishing = | ||

<!-- | |||

== Struers Labopol -25 == | == Struers Labopol -25 == | ||

[ | [https://www.struers.com/-/media/Library/Instruction-Manuals/English/Grinding-and-polishing/LaboPol-1-2-4-5-6-15207001-EN-Revision-0.pdf?dmc=1&ts=20180928T1014301571 User manual] | ||

[[File:labopol25.png|200px|left|thumb|Location Building 307, Prep Lab 109]]<br /> | [[File:labopol25.png|200px|left|thumb|Location Building 307, Prep Lab 109]]<br /> | ||

<br clear="all" /> | <br clear="all" /> | ||

--> | |||

== TechPrep Allied == | == TechPrep Allied == | ||

| Line 40: | Line 56: | ||

<br clear="all" /> | <br clear="all" /> | ||

<!-- | |||

== | == Struers Labopol -5 == | ||

[https://www.struers.com/-/media/Library/Instruction-Manuals/English/Grinding-and-polishing/LaboPol-1-2-4-5-6-15207001-EN-Revision-0.pdf?dmc=1&ts=20180928T1014301571 User manual] | |||

[[File:Labopol5.png|200px]|left|thumb|Location Building 307, Prep Lab 109]]<br /> | [[File:Labopol5.png|200px]|left|thumb|Location Building 307, Prep Lab 109]]<br /> | ||

| Line 47: | Line 65: | ||

<br clear="all" /> | <br clear="all" /> | ||

== | == Struers Labopol -4 == | ||

[https://www.struers.com/-/media/Library/Instruction-Manuals/English/Grinding-and-polishing/LaboPol-1-2-4-5-6-15207001-EN-Revision-0.pdf?dmc=1&ts=20180928T1014301571 User manual] | |||

[[File:Labopol4.png|200px|left|thumb|Location Building 307, Prep Lab 109]]<br /> | [[File:Labopol4.png|200px|left|thumb|Location Building 307, Prep Lab 109]]<br /> | ||

<br clear="all" /> | <br clear="all" /> | ||

--> | |||

== Dimple Grinder == | |||

[https://labmanager.dtu.dk/view_binary.php?class=MiscDocument&id=15&name=Manual+-+DIMPLING+GRINDER+MODEL+200.pdf Manual] ''- requires login'' | |||

[[File:Dimple_Grinder.jpg|200px|left|thumb|Location Building 307, Prep Lab 109]].<br /> | |||

<br clear="all" /> | |||

= Ion Milling = | = Ion Milling = | ||

<!-- | |||

== Fischione Low Angle Ion Milling and Polishing System Model 1010 == | == Fischione Low Angle Ion Milling and Polishing System Model 1010 == | ||

The Fischione Ion Mill is used for producing TEM specimens with large electron transparent areas. Samples are pre-thinned by e.g. mechanical grinding and polishing or chemical polishing. The milling or polishing is performed by argon ions. The instrument has two independently adjustable Hollow Anode Discharge (HAD) argon ion sources, which can be operated from 0.5 to 6.0 kV with currents from 3 mA to 8 mA. The milling angle can be adjusted in the range of 0° to 45°. Tuning the milling parameters allows for coarse or gentle milling and the goal is to get clean samples free of physical or chemical artifacts | The Fischione Ion Mill is used for producing TEM specimens with large electron transparent areas. Samples are pre-thinned by e.g. mechanical grinding and polishing or chemical polishing. The milling or polishing is performed by argon ions. The instrument has two independently adjustable Hollow Anode Discharge (HAD) argon ion sources, which can be operated from 0.5 to 6.0 kV with currents from 3 mA to 8 mA. The milling angle can be adjusted in the range of 0° to 45°. Tuning the milling parameters allows for coarse or gentle milling and the goal is to get clean samples free of physical or chemical artifacts | ||

[ | [https://labmanager.dtu.dk/view_binary.php?class=MiscDocument&id=15&name=Operation_Manual_Fischione_1010.pdf Manual] ''- requires login'' | ||

[[File:IMG_3674.JPG|300px|left|thumb|Location Building 307, Prep Lab 109]].<br /> | [[File:IMG_3674.JPG|300px|left|thumb|Location Building 307, Prep Lab 109]].<br /> | ||

<br clear="all" /> | <br clear="all" /> | ||

--> | |||

== Fischione NanoMill model 1040 == | == Fischione NanoMill model 1040 == | ||

This TEM specimen preparation system is an excellent tool for creating the high-quality thin specimens needed for advanced transmission electron microscopy imaging and analysis. It is ideal for both post-FIB (focused ion beam) processing and the enhancement of conventionally prepared specimens. | This TEM specimen preparation system is an excellent tool for creating the high-quality thin specimens needed for advanced transmission electron microscopy imaging and analysis. It is ideal for both post-FIB (focused ion beam) processing and the enhancement of conventionally prepared specimens. | ||

[http://www.fischione.com/products/ion-beam-preparation/model-1040-nanomill%C2%AE-tem-specimen-preparation-system | [http://www.fischione.com/products/ion-beam-preparation/model-1040-nanomill%C2%AE-tem-specimen-preparation-system Brochure] | ||

[[File:IMG_3679.JPG|250px|left|thumb|Location Building 314, Common Area]] | [[File:IMG_3679.JPG|250px|left|thumb|Location Building 314, Common Area]] | ||

| Line 75: | Line 103: | ||

<br clear="all" /> | <br clear="all" /> | ||

= Missing equipment = | |||

== Mini grinder/polisher == | == Mini grinder/polisher == | ||

= Sample preparation processes = | |||

Here we collected a few sample preparation processes done at DTU Nanolab building 314/307: | |||

*[[/FIB-lamella|FIB lamella preparation]] | |||

Latest revision as of 10:21, 19 November 2024

Feedback to this page: click here

This section is written by DTU Nanolab internal if nothing else is stated.

Mechanical preparation equipment is available for experience users, who know how to use the equipment. Access to the preparation lab is needed. We do not provide training on the equipment.

Cutting

Struers Minitom

Well Precision Diamond Wire Saw

Ultrasonic cutter

Manual - requires login

.

Grinding/Polishing

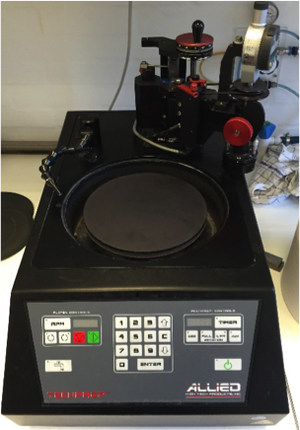

TechPrep Allied

The MultiPrep™ System enables precise semiautomatic sample preparation of a wide range of materials for microscopic (optical, SEM, FIB, TEM, AFM, etc.) evaluation.

Capabilities include parallel polishing, angle polishing, site-specific polishing or any combination thereof. It provides reproducible results by eliminating inconsistencies between users, regardless of their skill.

Dimple Grinder

Manual - requires login

.

Ion Milling

Fischione NanoMill model 1040

This TEM specimen preparation system is an excellent tool for creating the high-quality thin specimens needed for advanced transmission electron microscopy imaging and analysis. It is ideal for both post-FIB (focused ion beam) processing and the enhancement of conventionally prepared specimens.

Missing equipment

Mini grinder/polisher

Sample preparation processes

Here we collected a few sample preparation processes done at DTU Nanolab building 314/307: