Specific Process Knowledge/Lithography/5214E: Difference between revisions

Created page with "'''Feedback to this section''': '''[mailto:labadviser@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://http://labadviser.danchip.dtu.dk/index.php/Specific_Process_Kno..." |

|||

| (18 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

{{:Specific Process Knowledge/Lithography/authors_generic}} | |||

AZ 5214E is a positive UV photoresist with image reversal capability. | '''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Lithography/5214E click here]''' | ||

[[Category: Lithography|Resist]] | |||

[[Category: Resist|AZ 5214E]] | |||

__TOC__ | |||

==Resist description== | |||

AZ 5214E is a positive UV photoresist with image reversal capability. It is considered to have good adhesion when wet etching. | |||

==Spin coating== | ==Spin coating== | ||

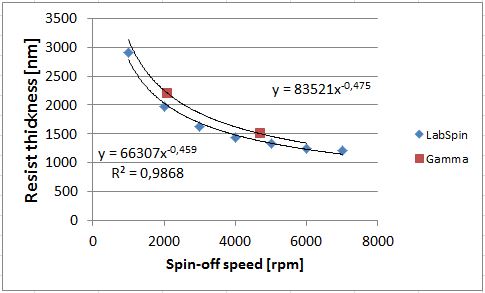

[[Image:5214Espincurves.JPG|500x500px|thumb|Spin curves for AZ 5214E (old German version) using a 30 s spin-off, and a 60s @ 90°C softbake]] | |||

'''Typical spin parameters:''' | |||

*Spin off: 30-60 s | |||

*Soft bake: 60 s @ 90°C | |||

<br clear="all" /> | <br clear="all" /> | ||

==Image reversal== | ==Image reversal== | ||

'''Typical image reversal parameters:''' | |||

*Reversal bake temperature: 110°C | |||

*Reversal bake time: 60 s | |||

*Flood exposure: 500 mJ/cm<sup>2</sup> | |||

If 5214E is baked after exposure, the exposed resist will cross-link, making it insoluble in the developer. | If 5214E is baked after exposure, the exposed resist will cross-link, making it insoluble in the developer. This is called the "Reversal bake". The reversal bake activates cross-linking of the exposed areas, which "reverses" the polarity of the design. When the substrate is flood-exposed after the reversal bake, the previously unexposed areas become soluble, and will be removed in the subsequent development. The image reversal procedure effectively makes AZ 5214E a negative resist. | ||

The image reversal process greatly increases the sensitivity of AZ 5214E, and the dose of the image exposure is a critical parameter, especially if negative resist sidewalls are desired. Half dose of the normal, positive process is a good starting point for optimization. Similarly, the reversal bake is also a critical step, and must be tightly controlled in order to achieve consistent results. If negative sidewalls are desired, | The image reversal process greatly increases the sensitivity of AZ 5214E, and the dose of the image exposure is a critical parameter, especially if negative angled resist sidewalls are desired.<br> | ||

Half dose of the normal, positive process is a good starting point for optimization. Similarly, the reversal bake is also a critical step, and must be tightly controlled in order to achieve consistent results. If negative sidewalls are desired, 60 - 120 s at 110°C is recommended (as well as a resist thickness above 2 µm), but if straight sidewalls are desired, 60 - 120 s at 120°C can be used. | |||

The flood exposure, on the other hand, is uncritical, and ~5 times the normal positive process dose is generally used. | |||

==Development== | ==Development== | ||

'''Development speed:''' | |||

*Puddle development in 2.38% TMAH (AZ 726 MIF): ~2 µm/min | |||

Latest revision as of 08:20, 13 April 2023

This section, including all images and pictures, is created by DTU Nanolab staff unless otherwise stated.

Feedback to this page: click here

Resist description

AZ 5214E is a positive UV photoresist with image reversal capability. It is considered to have good adhesion when wet etching.

Spin coating

Typical spin parameters:

- Spin off: 30-60 s

- Soft bake: 60 s @ 90°C

Image reversal

Typical image reversal parameters:

- Reversal bake temperature: 110°C

- Reversal bake time: 60 s

- Flood exposure: 500 mJ/cm2

If 5214E is baked after exposure, the exposed resist will cross-link, making it insoluble in the developer. This is called the "Reversal bake". The reversal bake activates cross-linking of the exposed areas, which "reverses" the polarity of the design. When the substrate is flood-exposed after the reversal bake, the previously unexposed areas become soluble, and will be removed in the subsequent development. The image reversal procedure effectively makes AZ 5214E a negative resist.

The image reversal process greatly increases the sensitivity of AZ 5214E, and the dose of the image exposure is a critical parameter, especially if negative angled resist sidewalls are desired.

Half dose of the normal, positive process is a good starting point for optimization. Similarly, the reversal bake is also a critical step, and must be tightly controlled in order to achieve consistent results. If negative sidewalls are desired, 60 - 120 s at 110°C is recommended (as well as a resist thickness above 2 µm), but if straight sidewalls are desired, 60 - 120 s at 120°C can be used.

The flood exposure, on the other hand, is uncritical, and ~5 times the normal positive process dose is generally used.

Development

Development speed:

- Puddle development in 2.38% TMAH (AZ 726 MIF): ~2 µm/min