Specific Process Knowledge/Thin film deposition/Lesker: Difference between revisions

m →rates |

|||

| (75 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto: | '''Feedback to this page''': '''[mailto:labadviser@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php/Specific_Process_Knowledge/Thin_film_deposition/Lesker click here]''' | ||

<i> Unless otherwise stated, this page is written by <b>DTU Nanolab internal</b></i> | |||

[[Category: Equipment|Thin film Sputter deposition Lesker]] | |||

[[Category: Thin Film Deposition|Sputter deposition Lesker]] | |||

[[image:Lesker 2014 with text2.jpg|right|400px]] | |||

== LESKER Sputter Tool== | == LESKER Sputter Tool== | ||

The purpose of the | The purpose of the Sputter-System (Lesker) is to deposit magnetic metals and dielectrica on a single 4" or 6" wafer at a time. | ||

It can be a problem to take wafers from the sputter and into the other machines in the cleanroom | It can be a problem to take wafers from the sputter system and into the other machines in the cleanroom since the sputter system is not very clean. In principle sputtering should therefore be the last step before you take your wafers out of the cleanroom. If you need to process your wafers further please contact the Thin Film group so they can help you. | ||

Lift off should never be done in the normal lift off bath in | Lift-off of magnetic materials should never be done in the normal lift-off bath in Cleanroom D-4. It should always be done in the dedicated lift-off bath in the fumehood next to the sputter system. | ||

| Line 22: | Line 28: | ||

*[[Specific Process Knowledge/Thin film deposition/Deposition of Silver|Silver (Ag)]] | *[[Specific Process Knowledge/Thin film deposition/Deposition of Silver|Silver (Ag)]] | ||

*[[Specific Process Knowledge/Thin film deposition/Deposition of Silicon|Silicon (Si)]] | *[[Specific Process Knowledge/Thin film deposition/Deposition of Silicon|Silicon (Si)]] | ||

*[[Specific Process Knowledge/Thin film deposition/Deposition of NiV/Sputtering of NiV in Lesker|NiV alloy]] | |||

*Iron (Fe) | *Iron (Fe) | ||

*+ many more ([[#List of available targets for the Sputter-System(Lesker) (03 June 2013)|see list below]] or ask) | *+ many more ([[#List of available targets for the Sputter-System(Lesker) (03 June 2013)|see list below]] or ask) | ||

Contact the | Contact the Thin Film group if you have special needs (thinfilm@danchip.dtu.dk). | ||

====Sputter rate==== | ====Sputter rate==== | ||

The sputter rate depends on | The sputter rate depends on | ||

| Line 33: | Line 41: | ||

* gas in chamber (Ar, N2, O2 or mixture). | * gas in chamber (Ar, N2, O2 or mixture). | ||

In the | In the table below ([[#Relative Sputter rates |Relative Sputter rates]]) there is a list of relative sputter rates for different materials (Al is set to 1). | ||

This means that | This means that you can estimate the sputter rate for a new material if you have the rate for another material under the same conditions (may only work for non-reactive sputtering, i.e., with Ar as the gas). | ||

== | ====Thickness uniformity==== | ||

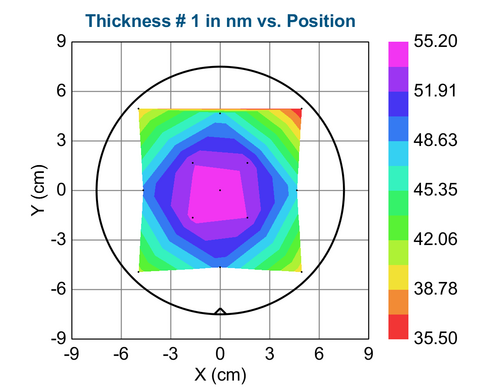

We have measured the thickness of a TiO<sub>x</sub> film deposited on a 6" Si wafer. The thickness measurement was done in the [[Specific Process Knowledge/Characterization/Optical_characterization#Ellipsometer_VASE_and_Ellipsometer_M-2000V|VASE ellipsometer]]. | |||

[[File:TiO2_150mm_13_points_from_lesker_20151103.png|500px|right]] | |||

Deposition parameters were: | |||

{| border="2" cellspacing="0" cellpadding="10" | {| border="2" cellspacing="0" cellpadding="10" | ||

|- | |- | ||

!style="background:silver; color:black;" align="left"| | !style="background:silver; color:black;" align="left"|Recipe | ||

|style="background: | |style="background:WhiteSmoke; color:black"|source 3 with oxygen | ||

|- | |||

!style="background:silver; color:black;" align="left"|time | |||

|style="background:WhiteSmoke; color:black"|600 s | |||

|- | |||

!style="background:silver; color:black;" align="left"|Gas | |||

|style="background:WhiteSmoke; color:black"|O<sub>2</sub>/Ar Ratio 10/100 | |||

|- | |- | ||

!style="background:silver; color:black" align="left | !style="background:silver; color:black;" align="left"|Pressure | ||

|style="background:WhiteSmoke; color:black"|3 mtorr | |||

|- | |- | ||

!style="background:silver; color:black;" align="left"| Gun | |||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| 3 | ||

|- | |- | ||

!style="background:silver; color:black" align="left | !style="background:silver; color:black;" align="left"|Target | ||

|style="background:WhiteSmoke; color:black"|Ti | |||

|style="background:WhiteSmoke; color:black"| | |||

|- | |- | ||

!style="background:silver; color:black;" align="left"|Power | |||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"|200 W | ||

|- | |- | ||

!style="background:silver; color:black;" align="left"|Voltage | |||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"|370V | ||

|- | |- | ||

!style="background:silver; color:black" align="left | !style="background:silver; color:black;" align="left"|Date | ||

|style="background:WhiteSmoke; color:black"|November 3<sup>rd</sup> 2015 | |||

|style="background:WhiteSmoke; color:black"| | |||

|- | |- | ||

|} | |} | ||

| Line 87: | Line 83: | ||

''By Bjarke Thomas Dalslet @Nanotech.dtu.dk'' | ''By Bjarke Thomas Dalslet @Nanotech.dtu.dk'' | ||

The Lesker CMS 18 sputter system can produce films in a wide range of qualities. The quality of a film depends strongly on the substrate (lattice matching), but also on the energy the sputtered material can utilize for annealing. | The Lesker CMS 18 sputter system can produce films in a wide range of crystalline qualities. The crystalline quality of a film depends strongly on the substrate (lattice matching), but also on the energy the sputtered material can utilize for annealing. | ||

*[[Specific_Process_Knowledge/Thin_film_deposition/Deposition_of_NiFe|Film quality optimization for NiFe films]]. | |||

==Surface roughness optimization== | ==Surface roughness optimization== | ||

''By Bjarke Thomas Dalslet @Nanotech.dtu.dk'' | ''By Bjarke Thomas Dalslet @Nanotech.dtu.dk'' | ||

The Lesker CMS 18 sputter system provides thin films of varying surface roughness. This roughness was verified to be dependent on the sputtered material, sputter mode (DC or RF) and the substrate bias strength. Other probable factors include sputter power and pressure | The Lesker CMS 18 sputter system provides thin films of varying surface roughness. This roughness was verified to be dependent on the sputtered material, sputter mode (DC or RF) and the substrate bias strength. Other probable factors include sputter power and pressure. | ||

The | The surface roughness dependence on the substrate bias strength can be found in the following pages for: | ||

*[[Specific_Process_Knowledge/Thin_film_deposition/Deposition_of_Silicon_Oxide/Deposition_of_Silicon_Oxide_using_Lesker_sputter_tool|SiO<sub>2</sub>]] | |||

*[[Specific_Process_Knowledge/Thin_film_deposition/Deposition_of_Silicon/Si_sputter_in_Sputter-System_Lesker|Si]] | |||

*[[Specific_Process_Knowledge/Thin_film_deposition/Deposition_of_Tantalum/Sputtering_of_Ta|Ta]] | |||

Other studies on metals (NiFe/MnIr) show only limited effect of the substrate bias on the roughness. | |||

==Stress in deposited films== | |||

Sputter deposition causes stress in the deposited material. Depending on the sputter parameters, the stress can be either tensile or compressive. In 2017 Radu Malureanu investigated the stress in NiFe, Si, Cr and Cu films deposited with the Lesker sputter system under a range of circumstances. | |||

Results of the study and links to further reading may be found here: | |||

*[[Specific Process Knowledge/Thin film deposition/Lesker/Stress dependence on sputter parameters in the Lesker sputter system|Stress dependence on sputter parameters]]. | |||

<br> | |||

==List of available targets for the Sputter-System(Lesker) (03 June 2013)== | ==List of available targets for the Sputter-System(Lesker) (03 June 2013)== | ||

| Line 267: | Line 115: | ||

|style="background:WhiteSmoke; color:black"|'''target thickness''' | |style="background:WhiteSmoke; color:black"|'''target thickness''' | ||

|style="background:WhiteSmoke; color:black"|'''Purity''' | |style="background:WhiteSmoke; color:black"|'''Purity''' | ||

|style="background:WhiteSmoke; color:black"|'''Max. Power (W)''' | |||

|style="background:WhiteSmoke; color:black"|'''Max Ramp up and down (W/s)''' | |||

|- | |- | ||

|Ag|| 0,250"|| 99,9% | |Ag|| 0,250"|| 99,9% || 314 || 20 | ||

|- | |- | ||

||Al|| 0,250"|| 99,99% | ||Al|| 0,250"|| 99,99% || 314 || 20 | ||

|- | |- | ||

|Au|| 0,125"|| 99,999% | |Au|| 0,125"|| 99,999% || 314 || 20 | ||

|- | |- | ||

| | |Cr|| 0,125"|| 99,95% || 251 || 20 | ||

|- | |- | ||

| | |Cu|| 0,250"|| 99,99% || 314 || 20 | ||

|- | |- | ||

| | |Fe|| 0,0625"|| 99,9% || 126 || 10 | ||

|- | |- | ||

| | |Ge|| 0,250"|| 99,999% || 126 || 0.5 | ||

|- | |- | ||

| | |Mg|| 0.250"|| 99,95% || 215 || 20 | ||

|- | |- | ||

| | |Mo|| 0,250"|| 99,95% || 314 || 20 | ||

|- | |- | ||

| | |Nb|| 0,250"|| 99,95% || 314 || 20 | ||

|- | |- | ||

| | |Ni|| 0,125"|| 99,9% || 188 || 10 | ||

|- | |- | ||

| | |Pd|| 0,125"|| 99,95% || 251 || 20 | ||

|- | |- | ||

| | |Pt|| 0,125"|| 99,95% || 251 || 20 | ||

|- | |- | ||

| | |Ru|| 0,125"|| 99,95% || 314 || 20 | ||

|- | |- | ||

| | |Si, Undoped|| 0,250"|| 99,999% || 126 || 0.5 | ||

|- | |- | ||

| | |Ta|| 0,250"|| 99,95% || 314 || 20 | ||

|- | |- | ||

| | |Te|| 0,250"|| 99,999% || 16 || 0.5 | ||

|- | |- | ||

| | |Ti|| 0,250"|| 99,7% || 251 || 20 | ||

|- | |- | ||

| | |Al2O3|| 0,125" + Cu backing plate|| 99,99% || 63 || 0.5 | ||

|- | |- | ||

|Al2O3|| 0, | |Al2O3|| 0,250"|| 99,99% || 63 || 0.5 | ||

|- | |- | ||

| | |Al/Cu99,5/0,5%|| 0,250"|| 99,99% || 314 || 20 | ||

|- | |- | ||

| | |Cr2O3|| 0,125" + Cu backing plate|| 99,8% || 63 || 0.5 | ||

|- | |- | ||

| | |Cu/Ti/25%|| 0,125"|| 99,99% || 251 || 20 | ||

|- | |- | ||

| | |Fe/Mn 50/50%|| 0,250"|| 99,95% || 126 || 10 | ||

|- | |- | ||

| | |ITO (In2O3/SnO2) 90/10%|| 0,125"|| 99,99% || 63 || 0.5 | ||

|- | |- | ||

| | |Mn/Ir80/20%|| 0,125"|| 99,9% || 251 || 20 | ||

|- | |- | ||

| | |MgO|| 0,125"|| 99,95% || 63 || 0.5 | ||

|- | |- | ||

| | |Ni/Co50/50%|| 0,0625"|| 99,95% || 126 || 20 | ||

|- | |- | ||

| | |Ni/Fe 80/20%|| 0.125"|| 99,95% || 126 || 20 | ||

|- | |- | ||

| | |NiV 93/7%|| 0,250"|| 99,95% || 157 || 20 | ||

|- | |- | ||

| | |SiC || 0,125" + Cu backing plate|| 99,5% || 63 || 0.5 | ||

|- | |- | ||

| | |Si3N4/MgO 2%|| 0,125"|| 99,9% || 63 || 0.5 | ||

|- | |- | ||

| | |SiO2|| 0,125"|| 99,995% || 126 || 0.5 | ||

|- | |- | ||

| | |SiO2|| 0,250"|| 99,995% || 126 || 0.5 | ||

|- | |- | ||

| | |Ta2O5|| 0,125"|| 99,900% || 63 || 0.5 | ||

|- | |- | ||

| | |AZO (ZnO/Al2O3) 98%/2% ||0,125"|| 99,99% || 126 || 0.5 | ||

|- | |- | ||

| | |ZnO|| 0.250"|| 99,999% || 63 || 0.5 | ||

|- | |- | ||

| | |ZrO(2)/Y(2)O(3)|| || 99,900% || 63 || 0.5 | ||

|- | |- | ||

| | |V|| 0.125"|| 99,500% || 188 || 20 | ||

|- | |- | ||

| | |W|| 0.250"|| 99,500% || 314 || 20 | ||

|- | |- | ||

| | |Hf|| 0.125"|| - || 188 || 20 | ||

|- | |- | ||

| | |Sn|| 0.250"|| - || 31 || 0.5 | ||

|} | |} | ||

== | |||

==Relative Sputter rates== | |||

To use these charts, locate the material for which known conditions are available. Then | |||

multiply the rate by the relative factors to arrive at the estimated rate for the new material. | |||

For example, with previous data showing 3.5Å/s Aluminum at 100W, then Titanium at | |||

similar conditions will generate approximately | |||

: (0.53/1.00)·3.5 Å/s ≅ 2 Å/s | |||

The rates in this table are calculated based on a 500V cathode potential. As the power is | |||

increased greater than two times the original rate, then the relative rate will drop slightly | |||

(up to 10%). For example, Aluminum at 250W | |||

: Al250W = 0.9·Al100W·(P1/P0) | |||

: 0.9·3.5 Å/s·(250/100) ≅ 7.4 Å/s | |||

The rates in the ceramics table assume the use of an RF power supply and account for the | |||

partial duty cycle of the RF generator as compared to a DC supply. | |||

===Metals and semiconductors=== | ===Metals and semiconductors=== | ||

{| border=2 cellspacing=0 cellpadding=10 | {| border=2 cellspacing=0 cellpadding=10 | ||

| Line 435: | Line 303: | ||

|style=background:WhiteSmoke; color:black|'''magn.''' | |style=background:WhiteSmoke; color:black|'''magn.''' | ||

|style=background:WhiteSmoke; color:black|'''Relative depostion rate''' | |style=background:WhiteSmoke; color:black|'''Relative depostion rate''' | ||

|- | |- | ||

|Cr||Chromium||Med||0.87 | |Cr||Chromium||Med||0.87 | ||

| Line 447: | Line 313: | ||

|- | |- | ||

|Ni80Fe20||Permalloy||High||0.80 | |Ni80Fe20||Permalloy||High||0.80 | ||

|} | |||

==Overview of the performance of Sputter-System(Lesker) and some process related parameters== | |||

{| border="2" cellspacing="0" cellpadding="10" | |||

|- | |||

!style="background:silver; color:black;" align="left"|Purpose | |||

|style="background:LightGrey; color:black"|Deposition of various materials ||style="background:WhiteSmoke; color:black"| | |||

* Metals including alloys and magnetic materials | |||

* Dielectrica including silica and alumina. | |||

* Semiconductors including silicon | |||

* See tables above and ask staff if there is a material you would like to deposit which you do not see listed. | |||

|- | |||

!style="background:silver; color:black" align="left" valign="top" rowspan="2"|Performance | |||

|style="background:LightGrey; color:black"|Film thickness||style="background:WhiteSmoke; color:black"| | |||

*Material dependent but generally up to hundreds of nm | |||

|- | |||

|style="background:LightGrey; color:black"|Deposition rates | |||

|style="background:WhiteSmoke; color:black"| | |||

*See [[#Relative Sputter rates |table]] above | |||

|- | |||

!style="background:silver; color:black" align="left" valign="top" rowspan="3"|Process parameter range | |||

|style="background:LightGrey; color:black"|Process Temperature | |||

|style="background:WhiteSmoke; color:black"| | |||

* usually room temp | |||

* We used to have sample heating to to more than 400°. However, this is not possible at the moment. | |||

* For sputtering with sample heating, please see [[Specific Process Knowledge/Thin film deposition/Cluster-based multi-chamber high vacuum sputtering deposition system|Sputter-system Metal-Oxide (PC1) and Sputter-system Metal-Nitride (PC3) ]] | |||

|- | |||

|style="background:LightGrey; color:black"|Process pressure | |||

|style="background:WhiteSmoke; color:black"| | |||

*3-10 mTorr | |||

|- | |||

|style="background:LightGrey; color:black"|Process Gases | |||

|style="background:WhiteSmoke; color:black"| | |||

*Ar | |||

*N<sub>2</sub> | |||

*O<sub>2</sub> | |||

*2 % O<sub>2</sub> in Ar | |||

* mixtures of the above | |||

|- | |||

!style="background:silver; color:black" align="left" valign="top" rowspan="3"|Substrates | |||

|style="background:LightGrey; color:black"|Batch size | |||

|style="background:WhiteSmoke; color:black"| | |||

*chips | |||

*4" | |||

*6" | |||

|- | |||

| style="background:LightGrey; color:black"|Substrate material allowed | |||

|style="background:WhiteSmoke; color:black"| | |||

*Silicon wafers | |||

*and almost any other as long as it does not degas. | |||

*See cross-contamination sheet [https://labmanager.dtu.dk/function.php?module=XcMachineaction&view=edit&MachID=244] | |||

|- | |||

| style="background:LightGrey; color:black"|Material allowed on the substrate | |||

|style="background:WhiteSmoke; color:black"| | |||

*almost any as long as it does not degas. | |||

|- | |||

|} | |} | ||

Latest revision as of 13:51, 22 January 2024

Feedback to this page: click here

Unless otherwise stated, this page is written by DTU Nanolab internal

LESKER Sputter Tool

The purpose of the Sputter-System (Lesker) is to deposit magnetic metals and dielectrica on a single 4" or 6" wafer at a time.

It can be a problem to take wafers from the sputter system and into the other machines in the cleanroom since the sputter system is not very clean. In principle sputtering should therefore be the last step before you take your wafers out of the cleanroom. If you need to process your wafers further please contact the Thin Film group so they can help you.

Lift-off of magnetic materials should never be done in the normal lift-off bath in Cleanroom D-4. It should always be done in the dedicated lift-off bath in the fumehood next to the sputter system.

The user manual, user APV and contact information can be found in LabManager:

Sputter-System(Lesker) in LabManager

Materials for sputtering

- Gold (Au)

- Nickel (Ni)

- Silver (Ag)

- Silicon (Si)

- NiV alloy

- Iron (Fe)

- + many more (see list below or ask)

Contact the Thin Film group if you have special needs (thinfilm@danchip.dtu.dk).

Sputter rate

The sputter rate depends on

- target material

- gun power (increasing power gives in general higher rate). Be aware of limitations on the power for different materials.

- chamber pressure (increasing pressure gives in general lower rate). Too low a pressure can make the plasma unstable.

- gas in chamber (Ar, N2, O2 or mixture).

In the table below (Relative Sputter rates) there is a list of relative sputter rates for different materials (Al is set to 1). This means that you can estimate the sputter rate for a new material if you have the rate for another material under the same conditions (may only work for non-reactive sputtering, i.e., with Ar as the gas).

Thickness uniformity

We have measured the thickness of a TiOx film deposited on a 6" Si wafer. The thickness measurement was done in the VASE ellipsometer.

Deposition parameters were:

| Recipe | source 3 with oxygen |

|---|---|

| time | 600 s |

| Gas | O2/Ar Ratio 10/100 |

| Pressure | 3 mtorr |

| Gun | 3 |

| Target | Ti |

| Power | 200 W |

| Voltage | 370V |

| Date | November 3rd 2015 |

Film quality optimization

By Bjarke Thomas Dalslet @Nanotech.dtu.dk

The Lesker CMS 18 sputter system can produce films in a wide range of crystalline qualities. The crystalline quality of a film depends strongly on the substrate (lattice matching), but also on the energy the sputtered material can utilize for annealing.

Surface roughness optimization

By Bjarke Thomas Dalslet @Nanotech.dtu.dk

The Lesker CMS 18 sputter system provides thin films of varying surface roughness. This roughness was verified to be dependent on the sputtered material, sputter mode (DC or RF) and the substrate bias strength. Other probable factors include sputter power and pressure.

The surface roughness dependence on the substrate bias strength can be found in the following pages for:

Other studies on metals (NiFe/MnIr) show only limited effect of the substrate bias on the roughness.

Stress in deposited films

Sputter deposition causes stress in the deposited material. Depending on the sputter parameters, the stress can be either tensile or compressive. In 2017 Radu Malureanu investigated the stress in NiFe, Si, Cr and Cu films deposited with the Lesker sputter system under a range of circumstances.

Results of the study and links to further reading may be found here:

List of available targets for the Sputter-System(Lesker) (03 June 2013)

| Deposition material | target thickness | Purity | Max. Power (W) | Max Ramp up and down (W/s) |

| Ag | 0,250" | 99,9% | 314 | 20 |

| Al | 0,250" | 99,99% | 314 | 20 |

| Au | 0,125" | 99,999% | 314 | 20 |

| Cr | 0,125" | 99,95% | 251 | 20 |

| Cu | 0,250" | 99,99% | 314 | 20 |

| Fe | 0,0625" | 99,9% | 126 | 10 |

| Ge | 0,250" | 99,999% | 126 | 0.5 |

| Mg | 0.250" | 99,95% | 215 | 20 |

| Mo | 0,250" | 99,95% | 314 | 20 |

| Nb | 0,250" | 99,95% | 314 | 20 |

| Ni | 0,125" | 99,9% | 188 | 10 |

| Pd | 0,125" | 99,95% | 251 | 20 |

| Pt | 0,125" | 99,95% | 251 | 20 |

| Ru | 0,125" | 99,95% | 314 | 20 |

| Si, Undoped | 0,250" | 99,999% | 126 | 0.5 |

| Ta | 0,250" | 99,95% | 314 | 20 |

| Te | 0,250" | 99,999% | 16 | 0.5 |

| Ti | 0,250" | 99,7% | 251 | 20 |

| Al2O3 | 0,125" + Cu backing plate | 99,99% | 63 | 0.5 |

| Al2O3 | 0,250" | 99,99% | 63 | 0.5 |

| Al/Cu99,5/0,5% | 0,250" | 99,99% | 314 | 20 |

| Cr2O3 | 0,125" + Cu backing plate | 99,8% | 63 | 0.5 |

| Cu/Ti/25% | 0,125" | 99,99% | 251 | 20 |

| Fe/Mn 50/50% | 0,250" | 99,95% | 126 | 10 |

| ITO (In2O3/SnO2) 90/10% | 0,125" | 99,99% | 63 | 0.5 |

| Mn/Ir80/20% | 0,125" | 99,9% | 251 | 20 |

| MgO | 0,125" | 99,95% | 63 | 0.5 |

| Ni/Co50/50% | 0,0625" | 99,95% | 126 | 20 |

| Ni/Fe 80/20% | 0.125" | 99,95% | 126 | 20 |

| NiV 93/7% | 0,250" | 99,95% | 157 | 20 |

| SiC | 0,125" + Cu backing plate | 99,5% | 63 | 0.5 |

| Si3N4/MgO 2% | 0,125" | 99,9% | 63 | 0.5 |

| SiO2 | 0,125" | 99,995% | 126 | 0.5 |

| SiO2 | 0,250" | 99,995% | 126 | 0.5 |

| Ta2O5 | 0,125" | 99,900% | 63 | 0.5 |

| AZO (ZnO/Al2O3) 98%/2% | 0,125" | 99,99% | 126 | 0.5 |

| ZnO | 0.250" | 99,999% | 63 | 0.5 |

| ZrO(2)/Y(2)O(3) | 99,900% | 63 | 0.5 | |

| V | 0.125" | 99,500% | 188 | 20 |

| W | 0.250" | 99,500% | 314 | 20 |

| Hf | 0.125" | - | 188 | 20 |

| Sn | 0.250" | - | 31 | 0.5 |

Relative Sputter rates

To use these charts, locate the material for which known conditions are available. Then multiply the rate by the relative factors to arrive at the estimated rate for the new material. For example, with previous data showing 3.5Å/s Aluminum at 100W, then Titanium at similar conditions will generate approximately

- (0.53/1.00)·3.5 Å/s ≅ 2 Å/s

The rates in this table are calculated based on a 500V cathode potential. As the power is increased greater than two times the original rate, then the relative rate will drop slightly (up to 10%). For example, Aluminum at 250W

- Al250W = 0.9·Al100W·(P1/P0)

- 0.9·3.5 Å/s·(250/100) ≅ 7.4 Å/s

The rates in the ceramics table assume the use of an RF power supply and account for the partial duty cycle of the RF generator as compared to a DC supply.

Metals and semiconductors

| Deposition material | name | Relative depostion rate |

| Ag | Silver | 2.88 |

| Al | Aluminum** | 1.00 |

| Au | Gold | 1.74 |

| Be | Beryllium | 0.21 |

| C | Carbon | 0.23 |

| Cu | Copper | 1.42 |

| GaAs | Gallium Arsenide {100} | 1.03 |

| GaAs | Gallium Arsenide {110} | 1.03 |

| Ge | Germanium | 1.50 |

| Mo | Molybdenum | 0.66 |

| Nb | Niobium | 0.76 |

| Pd | Palladium | 1.77 |

| Pt | Platinum | 1.00 |

| Re | Rhenium | 0.84 |

| Rh | Rhodium | 1.16 |

| Ru | Ruthenium | 0.98 |

| Si | Silicon | 0.60 |

| Sm | Samarium | 1.74 |

| Ta | Tantalum | 0.67 |

| Th | Thorium | 1.31 |

| Ti | Titanium | 0.53 |

| V | Vanadium | 0.50 |

| W | Tungsten | 0.57 |

| Y | Yttrium | 1.53 |

| Zr | Zirconium | 0.88 |

Oxides and Ceramics

| Deposition material | name | Relative depostion rate |

| Al2O3 | Alumina | 0.05 |

| SiC | Silicon Carbide | 0.22 |

| SiO2 | Silicon Dioxide | 0.21 |

| TaC | Tantalum Carbide | 0.09 |

| Ta2O5 | Tantalum Pentoxide | 0.39 |

Magnetic Materials

| Deposition material | name | magn. | Relative depostion rate |

| Cr | Chromium | Med | 0.87 |

| Fe | Iron | High | 0.57 |

| Mn | Manganese | Med | 0.14 |

| Ni | Nickel | Low | 0.86 |

| Ni80Fe20 | Permalloy | High | 0.80 |

| Purpose | Deposition of various materials |

|

|---|---|---|

| Performance | Film thickness |

|

| Deposition rates |

| |

| Process parameter range | Process Temperature |

|

| Process pressure |

| |

| Process Gases |

| |

| Substrates | Batch size |

|

| Substrate material allowed |

| |

| Material allowed on the substrate |

|