Specific Process Knowledge/Etch/DRIE-Pegasus/Pegasus-4/SiO2 Etch/SiO2 etch with resist mask: Difference between revisions

| Line 30: | Line 30: | ||

Model of all responses together. Se explaination on the responses below. <br> | Model of all responses together. Se explaination on the responses below. <br> | ||

Here they are fittet together (This gives a good overview but goes not give the best model each of the responses): | Here they are fittet together (This gives a good overview but goes not give the best model each of the responses): | ||

*Interactive HTM file (copy the link into your browser, this will only work if you have acess to the Nanolab cleanroom drive): '''<big>file:///O:/CleanroomDrive/_Equipment/Pegasus%204/DOE3/Fit%20Model%20all%20responses%202.htm</big>''' | *Interactive HTM file (copy the link into your browser, this will only work if you have acess to the Nanolab cleanroom drive): '''<big>file:///O:/CleanroomDrive/_Equipment/Pegasus%204/DOE3/Fit%20Model%20all%20responses%202.htm</big> - go to the bottom of the HTM page''' | ||

*Inactive PDF file: [[:File:Fit Model all responses 2.pdf]] | *Inactive PDF file: [[:File:Fit Model all responses 2.pdf]] | ||

Revision as of 12:51, 28 April 2021

Feedback to this page: click here

THIS PAGE IS UNDER CONSTRUCTION

Design of experiment "DOE03" - with DUV resist pattern

The design factors were:

- Coil power: 2500-4000 W

- Platen power: 200-300 W

- Total flow: 100-500 sccm

- He/C4F8 ratio: 5-30

- C4H8/H2 ratio: 1-3

Fixed settings were:

- Spacers used: 30 mm

- APC valve: 100% open (to keep pressure as low as possible) - Pressure will be very correlated to the total flow rate.

Samples:

- One piece 2x2cm DUV patterened bond to a Si carrier wafer

- ~2µm SiO2 - ~900nm Neg DUV resist - mask: Pegreticle

The responses I have evaluated are (See decribtions below):

- Etch rate of SiO2

- Etch rate selectivity to resist

- Etch profile angle in low aspect ratio areas

- Etch profile angle in higher aspect ratio areas

- Change in critical dimensions

- Aspect ratio dependent etch rate

Results from the run of DOE3 - with DUV resist pattern

Model of all responses together. Se explaination on the responses below.

Here they are fittet together (This gives a good overview but goes not give the best model each of the responses):

- Interactive HTM file (copy the link into your browser, this will only work if you have acess to the Nanolab cleanroom drive): file:///O:/CleanroomDrive/_Equipment/Pegasus%204/DOE3/Fit%20Model%20all%20responses%202.htm - go to the bottom of the HTM page

- Inactive PDF file: File:Fit Model all responses 2.pdf

Here the responses are fittet one at a time (This gives better models for the individual responses but the overview is less good:

- Interactive HTM file (copy the link into your browser, this will only work if you have acess to the Nanolab cleanroom drive): file:///O:/CleanroomDrive/_Equipment/Pegasus%204/DOE3/Fit%20Model%20all%20responses%20individually%20fit.htm

- Inactive PDF file: File:Fit Model all responses individually fit.pdf

About the .htm interactive files: Copy the htm link into your browser and the document will open if you have access to the Cleanroom drive. The prediction profiler is interactive! Be aware that the resulting response from the prediction profiler might have large statistical uncertainty. Unfortunately the document does not include the coinfidence interval so you should only use it as guide lines. If you look at the below .pdf file for one selected set of parameters in the prediection profiler to can see the coenfidence interval for that set of factors.

Explanation of the responses that are included in the models

Etch rate in low aspect ratio areas

Here I have modelled the etch rate in the low aspect ration etched areas (4 µm pitch and 1 µm lines).

Etch rate selectivity to the resist

This is defined as the SiO2 etch rate in the low aspect ratio etched areas (4 µm pitch and 1 µm lines) devided by the resist etch rate also on the 1 µm lines in these areas.

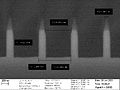

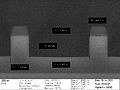

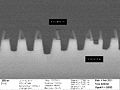

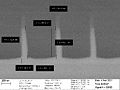

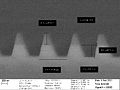

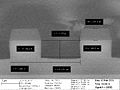

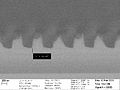

Etch profile angle in low aspect ratio etching

Modelling the etch profile angle is difficult because it depends on the aspect ratio of the etched structures. If the mask opening around the structure is small compared to the depth of the etch the aspect ratio is high. If the opening is large compared to the etch depth the aspect ratio is low. Here I have looked at low aspect ratio - more precisly I have looked at the profile of lines with 4 µm pitch and 1µm line width. The etch depth was been target to 1 µm. A different etch depth or a different starting thickness of the resist pattern will most likely give another profile angle.

Etch profile angle in 1:1 aspect ratio etching

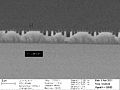

Modelling the etch profile angle is difficult because it depends on the aspect ratio of the etched structures. If the mask opening around the structure is small compared to the depth of the etch the aspect ratio is high. If the opening is large compared to the etch depth the aspect ratio is low. Here I have looked at 1:1 aspect ratio - more precisly I have looked at the profile of lines with 2 µm pitch and 1 µm line width. The etch depth was been target to 1 µm. A different starting thickness of the resist pattern will most likely give another profile angle. I have not modelled higher aspect ratio structures since for the higher spect ratio structures in this study some of the samples has not been etched at all in the small opening and then the profile angle response cannot be modelled.

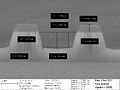

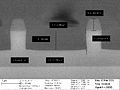

Change of critical dimensions (CD change)

Modelling the change in critical dimensions - that is the difference between the mask opening before etch and after etch. This has been measured as an average of the different size seen on the SEM images. It has been measured both in the top and the bottom. This modelling also includes the difference in CD change between top and bottom - this is actually another measure for the profile angle.

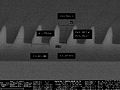

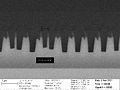

Aspect ratio dependent etch rate Different mask opening sizes etches with different rates - especially when the aspect ratio goes above 1 meaning the etch is deeper that the size of the opening. Here I have modelled the spect ratio dependant etch rate by modelling the ratio of the etch rate in the lines 4 µm pitch and 1 µm line over the etch rate in 1 µm pitch and 0.5µm lines. The etch depth in the large opening is about 1 µm.

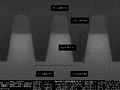

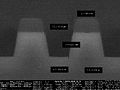

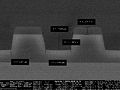

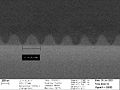

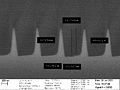

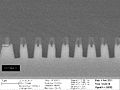

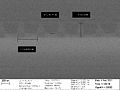

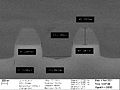

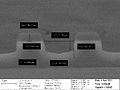

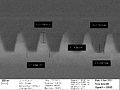

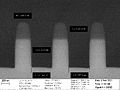

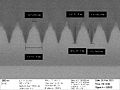

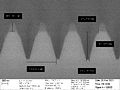

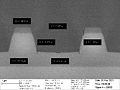

SEM images

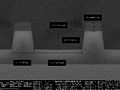

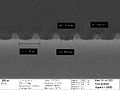

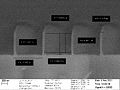

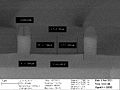

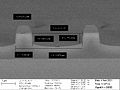

- Recipe no. 1: C06434_02 coil_3250W, platen:250W, He/C4F8= 17.5, C4F8/H2=2, Pressure:4.4mTorr C4F8:15.8sccm, He:276.3sccm, H2:7.9sccm, 4:51 min

- Missing

0.8µ/0.2µ

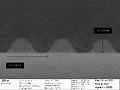

- Recipe no. 2: C06435_02 coil_3250W, platen:300W, He/C4F8= 30, C4F8/H2=3, Pressure:9.0mTorr, C4F8:16.0sccm, He:478.8sccm, H2:5.3sccm, 4:17 min

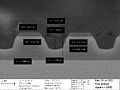

- Recipe no. 3: C06436_02 coil_4000W, platen:300W, He/C4F8= 5, C4F8/H2=3, Pressure:8.4mTorr, C4F8:78.9sccm, He:394.7sccm, H2:26.3sccm, 4:09 min

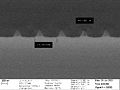

- Recipe no. 4: C06437_02 coil_2500W, platen:300W, He/C4F8= 5, C4F8/H2=1, Pressure:4.6mTorr, C4F8:42.9sccm, He:214.3sccm, H2:42.9sccm, 3:52 min

- Recipe no. 5: C06438_02 coil_4000W, platen:300W, He/C4F8= 30, C4F8/H2=1, Pressure:1.5mTorr, C4F8:3.1sccm, He:93.8sccm, H2:3.1sccm, 4:24 min

- Recipe no. 6: C06441_02 coil_3250W, platen:200W, He/C4F8= 5, C4F8/H2=1, Pressure:1.7mTorr, C4F8:14.3sccm, He:71.4sccm, H2:14.3sccm, 5:07 min

- Missing

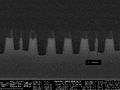

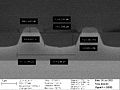

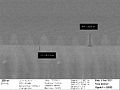

- Recipe no. 7: C06560_01 coil_4000W, platen:200W, He/C4F8= 5, C4F8/H2=1, Pressure:8.5mTorr, C4F8:71.4sccm, He:357.1sccm, H2:71.4sccm, 12:00 min

- Recipe no. 8: C06442_02 coil_4000W, platen:300W, He/C4F8= 5, C4F8/H2=2, Pressure:1.8mTorr, C4F8:15.4sccm, He:76.9sccm, H2:7.7sccm, 3:19 min

- Missing

- Recipe no. 9: C06444_02 coil_2500W, platen:200W, He/C4F8= 5, C4F8/H2=3, Pressure:8.9mTorr, C4F8:78.9sccm, He:394.7sccm, H2:26.3sccm, 3:19 min

- Missing

- Recipe no. 10: C06445_02 coil_2500W, platen:300W, He/C4F8= 17.5, C4F8/H2=1, Pressure:8.8mTorr, C4F8:25.6sccm, He:448.7sccm, H2:25.6sccm, 3:56 min

- Recipe no. 11: C06446_02 coil_2500W, platen:200W, He/C4F8= 30, C4F8/H2=1, Pressure:1.5mTorr, C4F8:3.1sccm, He:93.8sccm, H2:3.1sccm, 5:38 min

- Recipe no. 12: C06447_02 coil_4000W, platen:200W, He/C4F8= 30, C4F8/H2=2, Pressure:4.4mTorr, C4F8:9.6sccm, He:287.2sccm, H2:3.2sccm, 7:38 min

- None

0.4µ/0.2µ

Etch depth: nm

Resist left: nm

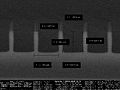

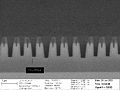

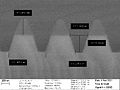

- Recipe no. 13: C06449_02 coil_2500W, platen:200W, He/C4F8= 30, C4F8/H2=2, Pressure:9.0mTorr, C4F8:15.9sccm, He:476.2sccm, H2: 7.9sccm, 7:10 min

- None

0.4µ/0.2µ

Etch depth: nm

Resist left: nm

- Recipe no. 14: C06450_02 coil_2500W, platen:250W, He/C4F8= 5, C4F8/H2=3, Pressure:1.6mTorr, C4F8:15.8sccm, He:78.9sccm, H2:5.3sccm, 3:51 min

- Recipe no. 15: C06451_02 coil_4000W, platen:250W, He/C4F8= 30, C4F8/H2=1, Pressure:9.0mTorr, C4F8:15.6sccm, He:468.7sccm, H2:15.6sccm, 6:17 min

- Recipe no. 16: C06452_02 coil_4000W, platen:200W, He/C4F8= 17.5, C4F8/H2=3, Pressure:1.6mTorr, C4F8:5.3sccm, He:92.9sccm, H2:1.8sccm, 5:05 min

- Recipe no. 17: C06453_02 coil_2500W, platen:300W, He/C4F8= 30, C4F8/H2=3, Pressure:2.1mTorr, C4F8:4.7sccm, He:142.2sccm, H2:1.6sccm, 4:19 min

- Recipe no. 18: C06454_02 coil_3250W, platen:250W, He/C4F8= 5, C4F8/H2=2, Pressure:4.6mTorr, C4F8:46.2sccm, He:230.8sccm, H2:23.1sccm, 5:16 min

- None

0.4µ/0.2µ

Etch depth: 0 nm

Resist left: nm

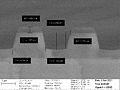

- Recipe no. 19: C06455_02 coil_3250W, platen:300W, He/C4F8= 5, C4F8/H2=1, Pressure:8.5mTorr, C4F8:71.4sccm, He:357.1sccm, H2:71.4sccm, 5:00 min

- None

0.4µ/0.2µ

Etch depth: 0 nm

Resist left: nm

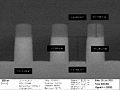

- Recipe no. 20: C06456_02 coil_2500W, platen:250W, He/C4F8= 17.5, C4F8/H2=3, Pressure:8.8mTorr, C4F8:26.5sccm, He:464.6sccm, H2:8.8sccm, 4:32 min

- Recipe no. 21: C06475_01 coil_3250W, platen:200W, He/C4F8= 30, C4F8/H2=1, Pressure:4.4mTorr, C4F8:9.4sccm, He:281.3sccm, H2:9.4sccm, 6:51 min

- None

0.4µ/0.2µ

Etch depth: nm

Resist left: nm

- Recipe no. 22: C06479_01 coil_3250W, platen:300W, He/C4F8= 17.5, C4F8/H2=2, Pressure:1.5mTorr, C4F8:5.3sccm, He:92.1sccm, H2:2.6sccm, 4:12 min

- Recipe no. 23: C06480_01 coil_4000W, platen:300W, He/C4F8= 17.5, C4F8/H2=2, Pressure:4.4mTorr, C4F8:15.8sccm, He:276.9sccm, H2:7.9sccm, 4:08 min

- Recipe no. 24: C06559_01 coil_4000W, platen:300W, He/C4F8= 30, C4F8/H2=3, Pressure:2.1mTorr, C4F8:4.7sccm, He:142.2sccm, H2:1.6sccm, 4:20 min

- Recipe no. 24: C06483_01 coil_4000W, platen:300W, He/C4F8= 30, C4F8/H2=3, Pressure:2.1mTorr, C4F8:4.7sccm, He:142.2sccm, H2:1.6sccm, 7:43 min

- None

0.4µ/0.2µ

Etch depth: nm

Resist left: nm - None

0.8µ/0.2µ

Etch depth: nm

Resist left: nm

- Recipe no. 25: C06484_01 coil_2500W, platen:300W, He/C4F8= 5, C4F8/H2=2, Pressure:9.2mTorr, C4F8:76.9sccm, He:384.6sccm, H2:38.5sccm, 3:35 min

- None

0.4µ/0.2µ

Etch depth: nm

Resist left: nm