Specific Process Knowledge/Lithography/PMMA: Difference between revisions

| (12 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

{|border="1" cellspacing=" | |||

'''Feedback to this page''': '''[mailto:lithography@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php?title=Specific_Process_Knowledge/Lithography/PMMA click here]''' | |||

{|border="1" cellspacing="1" cellpadding="3" style="text-align:left;" width="95%" | |||

|- | |- | ||

|- | |- | ||

|-style="background: | |-style="background:black; color:white" | ||

|'''Resist''' | |'''Resist''' | ||

|'''Polarity''' | |'''Polarity''' | ||

| Line 10: | Line 13: | ||

|'''Technical reports''' | |'''Technical reports''' | ||

|'''Spinner''' | |'''Spinner''' | ||

|'''Thinner''' | |||

|'''Developer''' | |'''Developer''' | ||

|'''Rinse''' | |'''Rinse''' | ||

| Line 16: | Line 20: | ||

|- | |- | ||

|- | |- | ||

|-style="background: | |-style="background:WhiteSmoke; color:black" | ||

|'''[[Specific_Process_Knowledge/Lithography/ | |'''[[Specific_Process_Knowledge/Lithography/PMMA|PMMA]]''' | ||

|Positive | |Positive | ||

|[http://www.allresist.com AllResist] | | [http://www.allresist.com AllResist] | ||

| | |We have various types of PMMA in the cleanroom. Please contact [mailto:Lithography@danchip.dtu.dk Lithography] for information. | ||

|[[media: | | [[media:MSDS PMMA.pdf|MSDS PMMA]], [[media:AR-P631_679.pdf|Processing guidelines]] | ||

|[[Specific_Process_Knowledge/Lithography/Coaters# | |See table <u>[[Specific_Process_Knowledge/Lithography/Coaters#Coaters:_Comparison_Table|here]] </u> | ||

| | |Anisole | ||

|IPA:H2O (7:3), MIBK:IPA (1:3) | |||

|IPA | |IPA | ||

| | |acetone/1165 | ||

| | | | ||

|} | |} | ||

<br><br> | |||

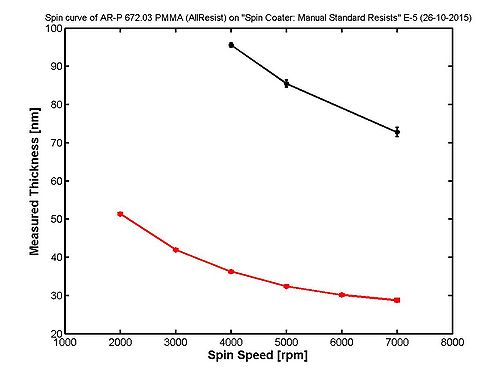

== Spin Curves == | == Spin Curves == | ||

The thickness is measured on VASE Ellipsometer using a simple Cauchy model for a transparent polymer on Si. The measurements are performed at one incidence angle (70 degrees) only. 9 points on each 4" wafer has been measured; the standard deviation thus representing the homogeinity of the film on the 4" wafers. | The thickness is measured on VASE Ellipsometer using a simple Cauchy model for a transparent polymer on Si. The measurements are performed at one incidence angle (70 degrees) only. 9 points on each 4" wafer has been measured; the standard deviation thus representing the homogeinity of the film on the 4" wafers. Please notice, that the spinning curves were made in 2015. | ||

[[File:SpinCurvePMMA.jpg|right|500px]] | |||

{|border="1" cellspacing="0" cellpadding="3" style="text-align:left;" style="width: 40%" | {|border="1" cellspacing="0" cellpadding="3" style="text-align:left;" style="width: 40%" | ||

| Line 52: | Line 61: | ||

|-style="background:silver; color:black" | |-style="background:silver; color:black" | ||

!Spin Speed [rpm] | !Spin Speed [rpm] | ||

!Acceleration [ | !Acceleration [rpm/s] | ||

!Thickness [nm] | !Thickness [nm] | ||

!St Dev | !St Dev | ||

| Line 95: | Line 104: | ||

|-style="background:silver; color:black" style="text-align:left;" | |-style="background:silver; color:black" style="text-align:left;" | ||

!Spin Speed [rpm] | !Spin Speed [rpm] | ||

!Acceleration [ | !Acceleration [rpm/s] | ||

!Thickness [nm] | !Thickness [nm] | ||

!St Dev | !St Dev | ||

Latest revision as of 14:11, 20 January 2020

Feedback to this page: click here

| Resist | Polarity | Manufacturer | Comments | Technical reports | Spinner | Thinner | Developer | Rinse | Remover | Process flows (in docx-format) |

| PMMA | Positive | AllResist | We have various types of PMMA in the cleanroom. Please contact Lithography for information. | MSDS PMMA, Processing guidelines | See table here | Anisole | IPA:H2O (7:3), MIBK:IPA (1:3) | IPA | acetone/1165 |

Spin Curves

The thickness is measured on VASE Ellipsometer using a simple Cauchy model for a transparent polymer on Si. The measurements are performed at one incidence angle (70 degrees) only. 9 points on each 4" wafer has been measured; the standard deviation thus representing the homogeinity of the film on the 4" wafers. Please notice, that the spinning curves were made in 2015.

| AllResist AR-P 672.03 (PMMA) (~ 2ml per 4" wafer) spin coated on 'Spin Coater: Manual Standard Resists, E-5, WILTID & TIGRE, 26-10-2015. Softbake 3 min @ 150 degC. | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [rpm/s] | Thickness [nm] | St Dev | |||

| 4000 | 2000 | 95.55 | 0.55 | |||

| 5000 | 2000 | 85.50 | 0.92 | |||

| 7000 | 2000 | 72.79 | 1.18 | |||

| AllResist AR-P 672.03 (PMMA) diluted 1:1 in Anisole (~ 2ml per 4" wafer) spin coated on 'Spin Coater: Manual Standard Resists, E-5, WILTID & TIGRE, 26-10-2015. Softbake 3 min @ 150 degC. | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [rpm/s] | Thickness [nm] | St Dev | |||

| 2000 | 2000 | 51.37 | 0.25 | |||

| 3000 | 2000 | 41.97 | 0.24 | |||

| 4000 | 2000 | 36.25 | 0.25 | |||

| 5000 | 2000 | 32.42 | 0.30 | |||

| 6000 | 2000 | 30.17 | 0.29 | |||

| 7000 | 2000 | 28.76 | 0.43 | |||