|

|

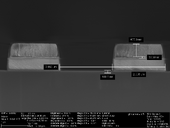

| Line 295: |

Line 295: |

| =Etch test of Silicon Nitride= | | =Etch test of Silicon Nitride= |

|

| |

|

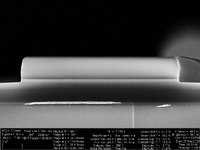

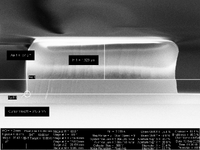

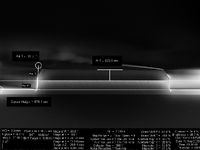

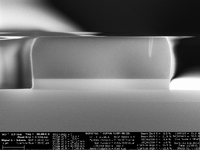

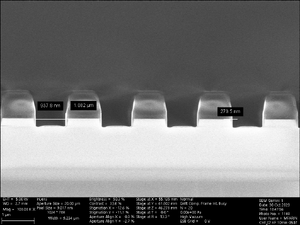

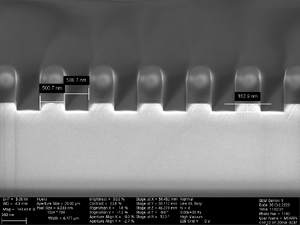

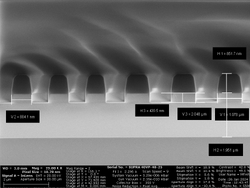

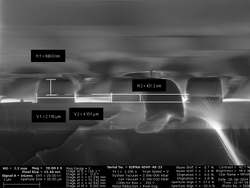

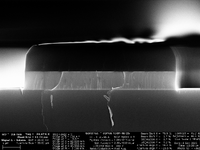

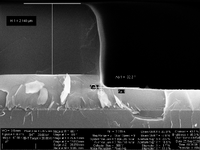

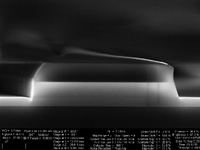

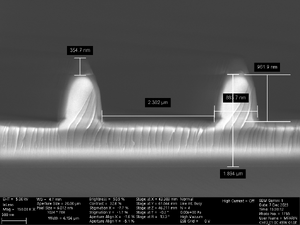

| Tested on chips (2*2cm). The following results were processed on chips bonded to a 100mm dummy wafer. They were patterned with 750 DUV resist and 65nm of BARC (exposure:355 J/m2, focus:-3.1). The nitride layer was 560nm, deposited on the PECVD4 (Standard HF SiN with wafer clean).

| | The nitride layer deposited was 560nm, on the PECVD4 (recipe: Standard HF SiN with wafer clean, for 1h). |

| | | They were patterned with 750 DUV resist and 65nm of BARC (exposure:355 J/m2, focus:-3.1). |

| | The following results were processed on chips (2*2cm) bonded to a 100mm dummy wafer. |

|

| |

|

|

| |

|

Revision as of 14:57, 22 April 2024

Tests performed with UV resist:

The tests were performed on a 100mm wafer patterned on MLA3, with 2.2um AZ5214E resist.

| Recipe

|

Recipe parameters

|

Duration (min)

|

Date

|

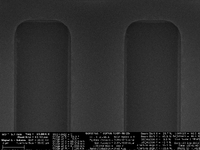

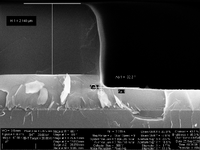

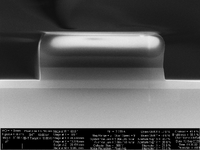

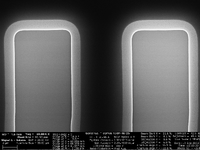

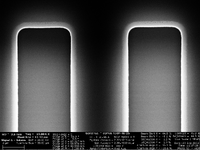

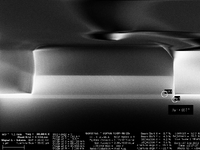

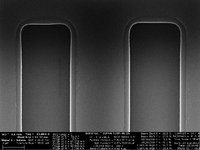

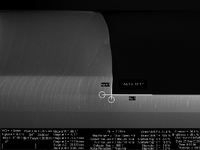

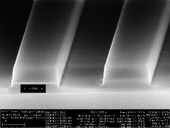

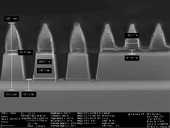

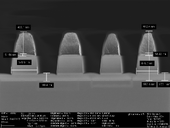

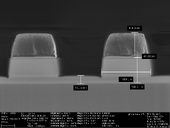

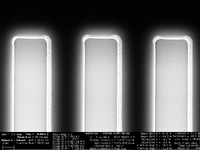

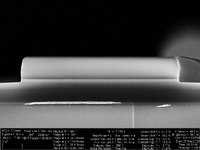

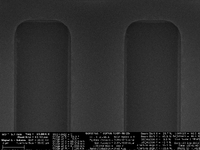

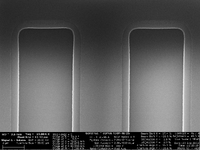

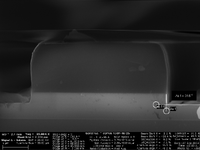

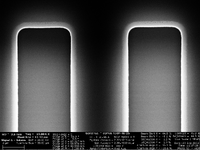

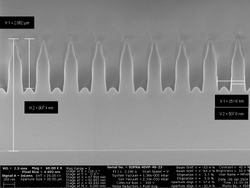

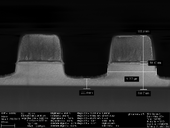

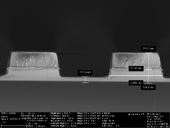

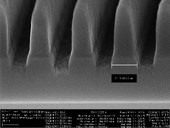

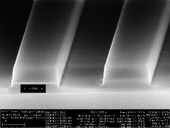

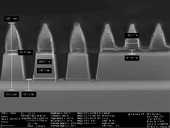

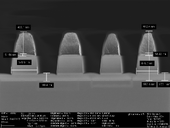

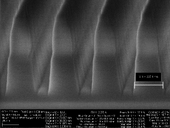

SEM picture

|

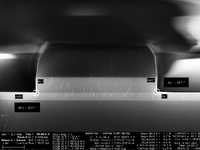

Redeposition - top view

|

Profile angles

|

Etch rate in SiO2

|

Etch rate in resist

(AZ5214E inverse)

|

Selectivity

(SiO2:resist)

|

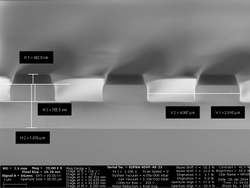

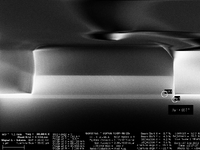

| CHF3_t1

|

CHF3= 22.5 sccm

Coil= 800W

Platen= 15W

Press= 2.5mTorr

Temp= 20°C

|

12:00

|

04/09/2023

|

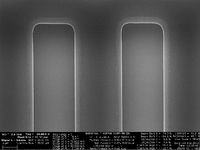

|

|

|

69.7 nm/min

+/- 10.5%

|

57.3 nm/min

+/- 12.9%

|

1.22

|

| CHF3_t2

|

CHF3= 22.5 sccm

Coil= 150W

Platen= 25W

Press= 2.5mTorr

Temp= 20°C

|

25:00

|

04/09/2023

|

|

|

|

26.7 nm/min

+/- 11.9%

|

24.2 nm/min

+/- 21.1%

|

1.1

|

| CHF3 t2

|

CHF3= 22.5 sccm

H2= 22.5 sccm

Coil= 150W

Platen= 25W

Press= 2.5mTorr

Temp= 20°C

|

10:00

|

22/09/2023

|

|

|

|

9,7 nm/min

+/- 34.4%

|

1,8 nm/min

+/- 46.5%

|

5.4

|

| CHF3_t1

|

CHF3= 22.5 sccm

H2= 10 sccm

Coil= 800W

Platen= 15W

Press= 2.5mTorr

Temp= 20°C

|

10:00

|

12/09/2023

|

|

|

|

59,6 nm/min

+/- 12.9%

|

47,5 nm/min

+/- 21.5%

|

1.25

|

| CHF3_t1

|

CHF3= 22.5 sccm

O2= 10 sccm

Coil= 800W

Platen= 15W

Press= 2.5mTorr

Temp= 20°C

|

10:00

|

11/09/2023

|

|

|

|

60,6 nm/min

+/- 10.1%

|

130,8 nm/min

+/- 8.8%

|

0.46

|

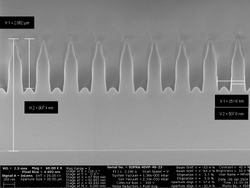

| CHF3 t1

|

CHF3= 22.5 sccm

H2= 22.5 sccm

Coil= 800W

Platen= 15W

Press= 2.5mTorr

Temp= 20°C

|

10:00

|

20/09/2023

|

|

|

|

47,3 nm/min

+/- 12%

|

26,4 nm/min

+/- 17,4%

|

1.8

|

| CHF3 t1

|

CHF3= 22.5 sccm

H2= 35 sccm

Coil= 800W

Platen= 15W

Press= 2.5mTorr

Temp= 20°C

|

10:00

|

22/09/2023

|

|

|

|

36,5 nm/min

+/- 10.6%

|

17,5 nm/min

+/- 13.9%

|

2.09

|

| CHF3 t1

|

CHF3= 35 sccm

H2= 35 sccm

Coil= 800W

Platen= 15W

Press= 2.5mTorr

Temp= 20°C

|

10:00

|

22/09/2023

|

|

|

|

42 nm/min

+/- 15.4%

|

23,8 nm/min

+/- 22.2%

|

1.76

|

| CHF3 t1

|

CHF3= 22.5 sccm

CF4= 22.5 sccm

Coil= 800W

Platen= 15W

Press= 2.5mTorr

Temp= 20°C

|

10:00

|

22/09/2023

|

|

|

|

75,8 nm/min

+/- 13.1%

|

74,9 nm/min

+/- 10.8%

|

1.01

|

| CHF3 t1

|

CHF3= 22.5 sccm

H2= 22.5 sccm

Coil= 800W

Platen= 15W

Press= 25mTorr

Temp= 20°C

|

10:00

|

22/09/2023

|

|

|

|

-

|

-

|

no etch done,

polymer deposited

|

| CHF3 t1

|

CHF3= 22.5 sccm

H2= 22.5 sccm

Coil= 800W

Platen= 15W

Press= 2.5mTorr

Temp= 0°C

|

10:00

|

22/09/2023

|

|

|

|

48 nm/min

+/- 11.2%

|

23,3 nm/min

+/- 13.7%

|

2.06

|

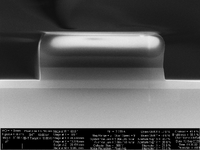

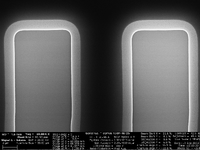

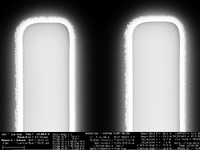

Tests performed with DUV resist:

The resist used was a negative DUV resist (UVN) with 915nm + 88nm BARC layer.

| Recipe

|

Recipe parameters

|

Duration (min)

|

Date

|

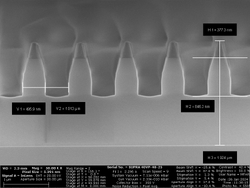

SEM picture

|

Etch rate in SiO2

|

Etch rate in resist

(UVN)

|

Selectivity

(SiO2:resist)

|

| CHF3_t1

|

CHF3= 22.5 sccm

H2= 22.5 sccm

Coil= 800W

Platen= 30W

Press= 2.5mTorr

Temp= 20°C

|

10:00

|

13/11/23

|

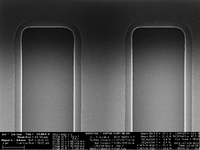

|

47

|

24.6

|

1.9

|

| CHF3_t1

|

CHF3= 22.5 sccm

H2= 22.5 sccm

Coil= 800W

Platen= 45W

Press= 2.5mTorr

Temp= 20°C

|

10:00

|

13/11/23

|

|

59

|

30

|

1.9

|

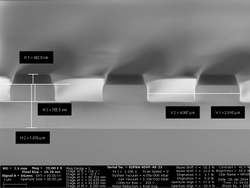

| CHF3_t1

|

CHF3= 22.5 sccm

H2= 22.5 sccm

Coil= 800W

Platen= 45W

Press= 2.5mTorr

Temp= 0°C

|

10:00

|

07/12/23

|

|

96

|

56

|

1.7

|

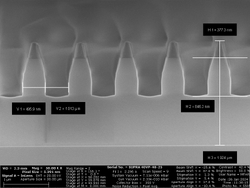

| CHF3_t2

|

CHF3= 22.5 sccm

H2= 22.5 sccm

Coil= 150W

Platen= 25W

Press= 2.5mTorr

Temp= 20°C

|

10:00

|

23/10/23

|

|

27

|

12,5

|

2.1

|

| CHF3_t2

|

CHF3= 22.5 sccm

H2= 22.5 sccm

Coil= 150W

Platen= 25W

Press= 2.5mTorr

Temp= 20°C

|

20:00

|

23/10/23

|

|

8.15

|

7.5

|

1.1

|

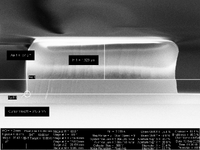

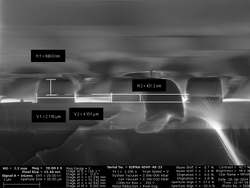

2SiO2 test - 5 jan 2024

Tested on chips (2*2cm). The following results were processed on chips bonded to a 100mm wafer. They were patterned with 915 UVN resist (DUV negative) and 65nm of BARC. The SiO2 layer was 2um (deposited on the C1 furnace).

| Recipe

|

Time (min)

|

Date

|

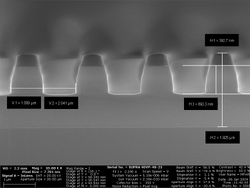

SEM picture

|

Etch rate SiN (nm/min)

|

Etch rate resist (nm/min)

|

Selectivity

(SiN:resist)

|

CHF3_t1

CHF3= 22.5 sccm

H2= 22.5 sccm

Coil= 800W

Platen= 30W

Press= 2.5mTorr

Temp= 20°C

|

10:00

|

25/01

-2024

|

|

250nm- 61,99

500nm- 68,12

1000nm- 74,7

2000nm- 76,55

|

250nm- 61,31

500nm- 49,85

1000nm- 46,83

2000nm- 47,3

|

250nm- 1,01

500nm- 1,37

1000nm- 1,6

2000nm- 1,62

|

CHF3_t1

CHF3= 22.5 sccm

H2= 22.5 sccm

Coil= 150W

Platen= 45W

Press= 2.5mTorr

Temp= 20°C

|

10:00

|

25/01

-2024

|

|

250nm- 90,74

500nm- 84,63

1000nm- 89,33

2000nm- 94,34

|

250nm- 81,1

500nm- 53,77

1000nm- 52,23

2000nm- 54,81

|

250nm- 1,12

500nm- 1,57

1000nm- 1,71

2000nm- 1,72

|

CHF3_t2

CF4= 22.5 sccm

H2= 22.5 sccm

Coil= 150W

Platen= 45W

Press= 2.5mTorr

Temp= 20°C

|

15:00

|

25/01

-2024

|

*it's visible that redeposits, so the ER and selectivity may not be correct.

|

250nm- 9,18

500nm- 22,46

1000nm- 28,03

2000nm- 28,75

|

250nm- 11,09

500nm- 3,96

1000nm- 4,22

2000nm- 4,40

|

250nm- 0,83

500nm- 5,67

1000nm- 6,64

2000nm- 6,5

|

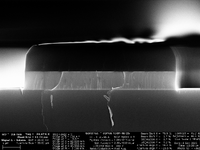

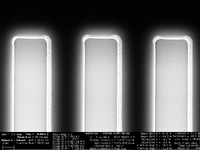

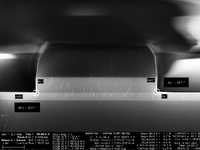

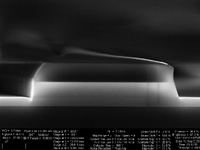

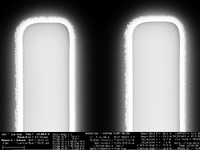

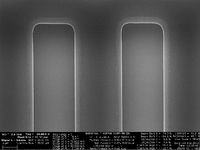

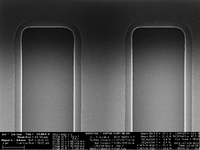

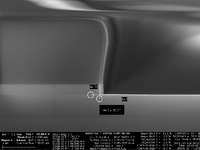

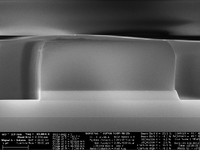

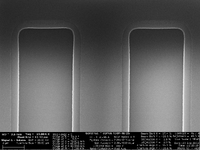

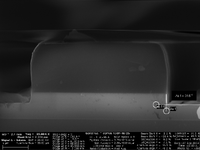

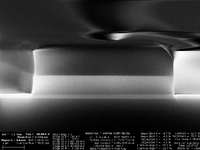

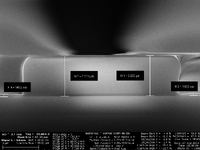

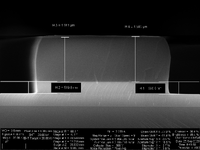

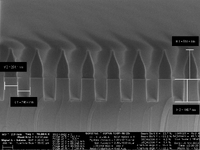

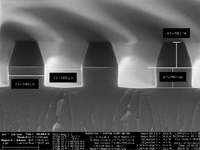

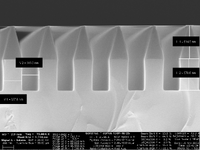

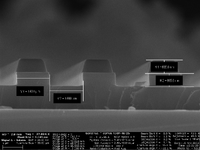

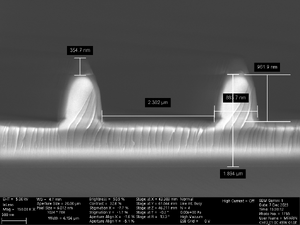

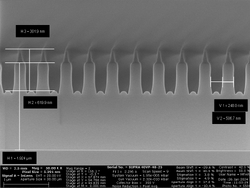

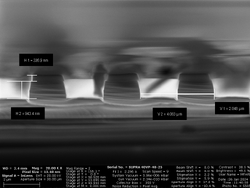

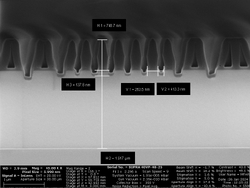

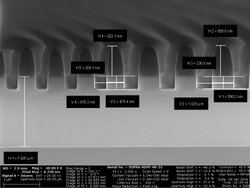

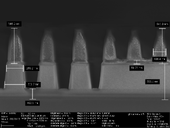

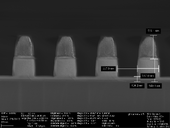

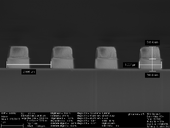

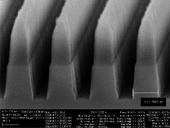

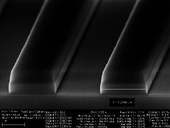

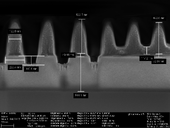

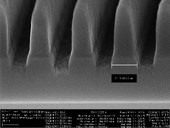

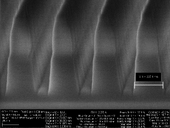

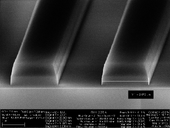

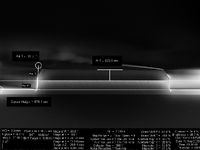

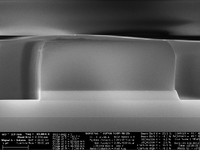

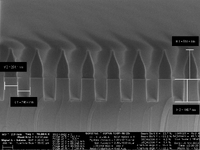

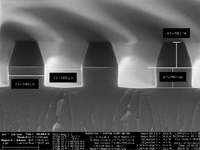

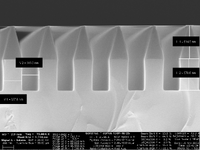

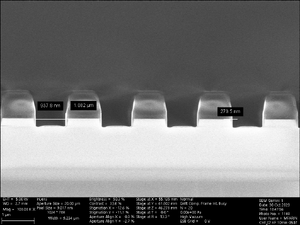

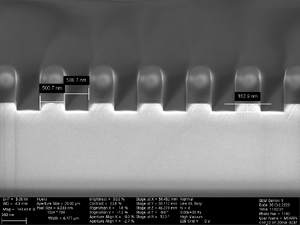

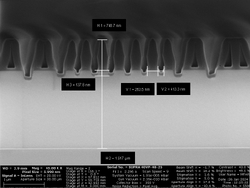

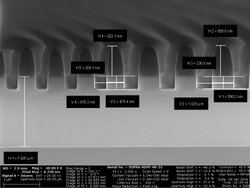

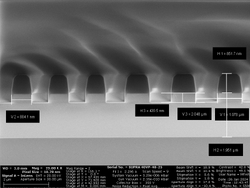

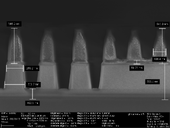

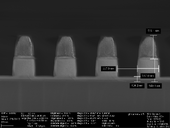

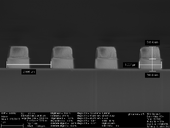

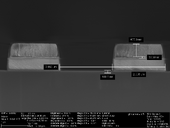

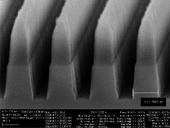

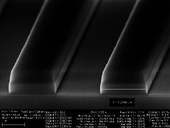

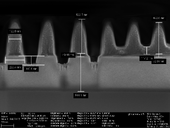

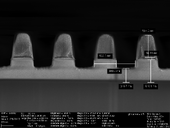

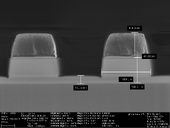

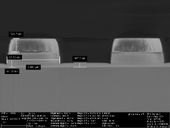

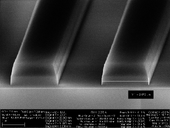

Etch test of Silicon Nitride

The nitride layer deposited was 560nm, on the PECVD4 (recipe: Standard HF SiN with wafer clean, for 1h).

They were patterned with 750 DUV resist and 65nm of BARC (exposure:355 J/m2, focus:-3.1).

The following results were processed on chips (2*2cm) bonded to a 100mm dummy wafer.

| Recipe

|

Time (min)

|

Date

|

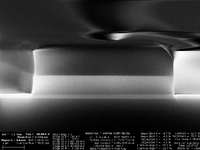

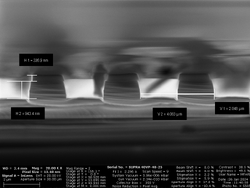

SEM picture

|

Redeposition - top view

|

Etch rate SiN (nm/min)

|

Etch rate resist (nm/min)

|

Selectivity

(SiN:resist)

|

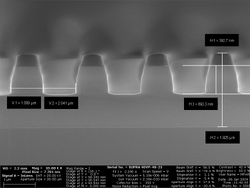

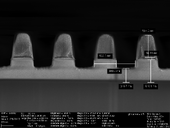

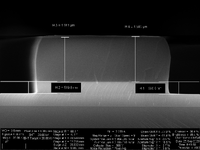

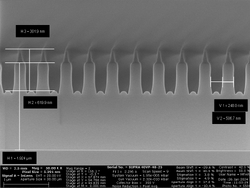

CHF3_t1

CHF3= 22.5 sccm

H2= 22.5 sccm

Coil= 800W

Platen= 15W

Press= 2.5mTorr

Temp= 20°C

|

2:30

|

29/02

-2024

|

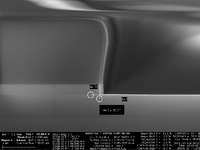

|

|

250nm- 155,08

500nm- 170,32

1000nm- 174,45

2000nm- 179,76

|

250nm- 65,52

500nm- 56,36

1000nm- 64,56

2000nm- 68,84

|

250nm- 2,37

500nm- 3,02

1000nm- 2,70

2000nm- 2,61

|

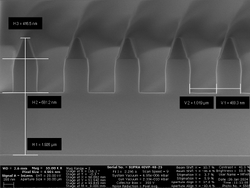

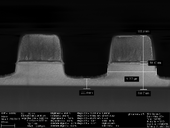

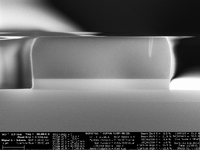

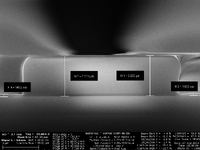

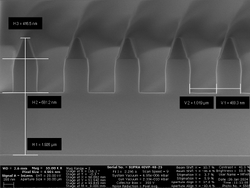

CHF3_t2

CHF3= 22.5 sccm

H2= 22.5 sccm

Coil= 150W

Platen= 45W

Press= 2.5mTorr

Temp= 20°C

|

5:00

|

29/02

-2024

|

|

|

250nm- 28,12

500nm- 41,86

1000nm- 66

2000nm- 63,62

|

250nm- 23,26

500nm- 22,60

1000nm- 16,74

2000nm- 15,34

|

250nm- 1.21

500nm- 1.85

1000nm- 3.94

2000nm- 4.15

|

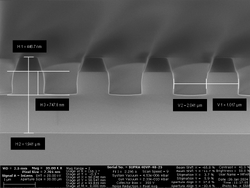

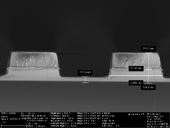

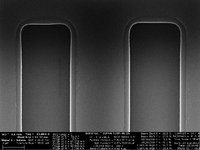

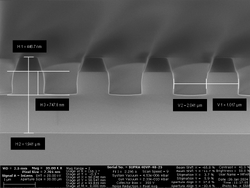

CF4lowCP

CF4= 22.5 sccm

H2= 22.5 sccm

Coil= 150W

Platen= 45W

Press= 2.5mTorr

Temp= 20°C

|

5:00

|

29/02

-2024

|

|

|

250nm- 76,50

500nm- 73,92

1000nm- 73,94

2000nm- 76,50

|

250nm- 44,98

500nm- 33,52

1000nm- 31,16

2000nm- 25,66

|

250nm- 1,70

500nm- 2,21

1000nm- 2,37

2000nm- 2,98

|