|

|

| Line 215: |

Line 215: |

| <br> | | <br> |

|

| |

|

| ===Recipes and results - <span style="background:#FFD850">CF<sub>4</sub> / H<sub>2</sub> tests</span> === | | ===Recent results - <span style="background:#FFD850">CF<sub>4</sub> / H<sub>2</sub> tests</span> === |

|

| |

|

| The following results were processed on chips bonded to a 100mm wafer. They were patterned with 915 UVN resist (DUV negative) and 65nm of BARC. The SiO2 layer was 2um (deposited on the C1 furnace). | | The following results were processed on chips bonded to a 100mm wafer. They were patterned with 915 UVN resist (DUV negative) and 65nm of BARC. The SiO2 layer was 2um (deposited on the C1 furnace). |

Revision as of 14:03, 22 April 2024

More test with CF4/H2 - SiO2 etch

Tests performed by Maria Farinha @DTU Nanolab

The gas flows were combined and the following results were achieved. It´s visible that with higher CF4 the selectivity is not good, so by adding H2, until 1:1, the selectivity improves. Additionally, the uniformity gets slightly worse while going for 1:1 of gas chemistry.

The recipe CF4lowCP 22.5/22.5 seems to be the only one good enough to use. It is a slow etch recipe, with good selectivity with AZ5214E resist.

| CF4ICP

|

SiO2 ER (nm/min)

|

Uniformity (SiO2 etch)

|

Selectivity (SiO2:resist)

|

Si3N4 ER (nm/min)

|

SixN ER (nm/min)

|

| 45 CF4 + 0 H2

|

71.4

|

11.7%

|

0.74

|

-

|

-

|

| 35 CF4 + 10 H2

|

69

|

12.6%

|

0.89

|

-

|

-

|

| 22.5 CF4 + 22.5 H2

|

58.6

|

13.3%

|

1.43

|

84.4

|

42.9

|

- The uniformity considers a 100mm wafer, calculated with 5 points.

| CF4lowCP

|

SiO2 ER (nm/min)

|

Uniformity (SiO2 etch)

|

Selectivity (SiO2:resist)

|

Si3N4 ER (nm/min)

|

SixN ER (nm/min)

|

| 45 CF4 + 0 H2

|

24.9

|

11.5%

|

0.47

|

-

|

-

|

| 35 CF4 + 10 H2

|

22.6

|

11.6%

|

0.64

|

-

|

-

|

| 22.5 CF4 + 22.5 H2

|

17.8

|

13.7%

|

1.85

|

28

|

22.5

|

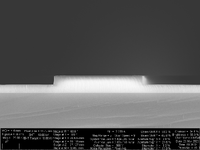

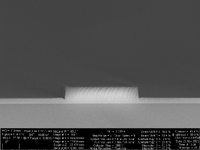

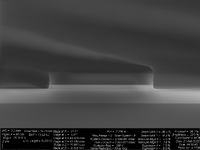

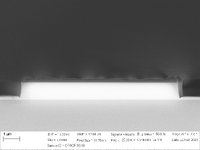

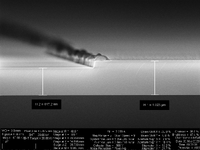

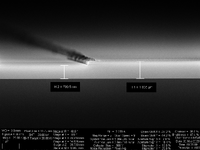

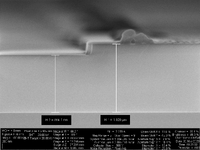

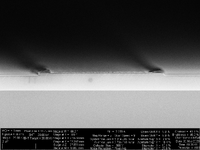

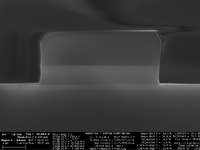

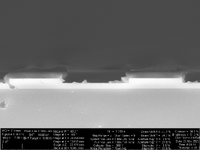

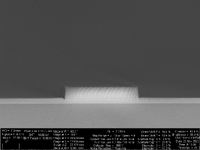

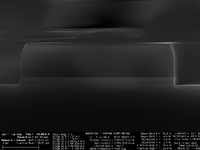

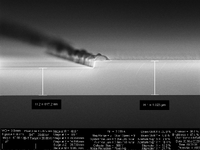

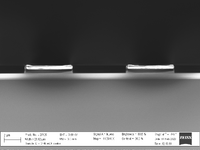

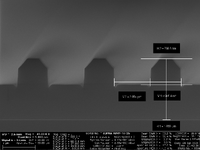

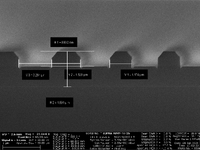

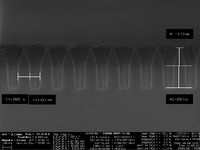

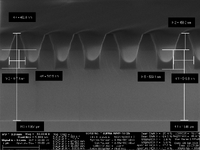

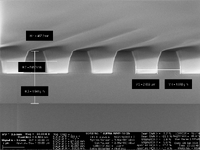

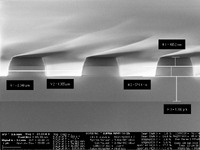

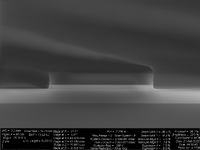

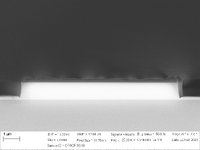

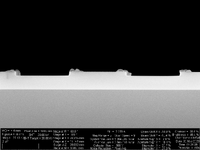

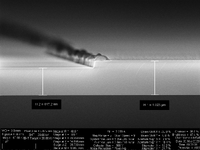

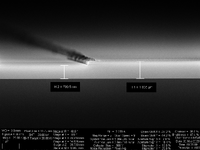

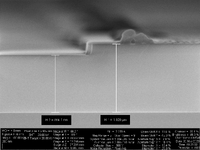

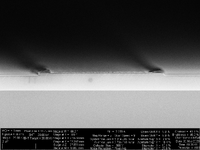

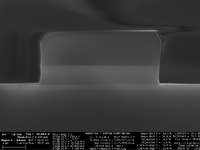

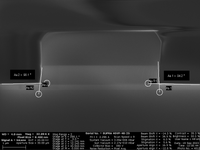

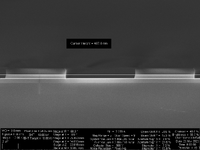

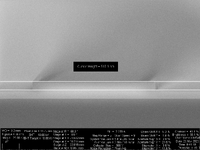

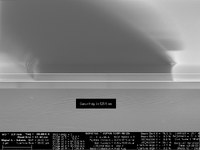

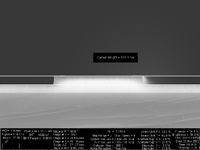

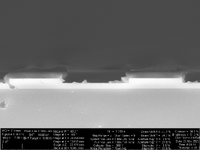

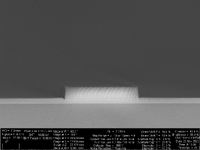

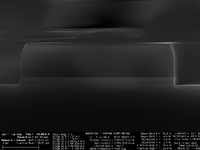

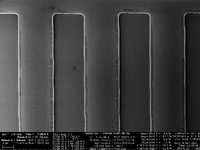

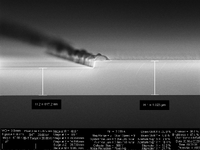

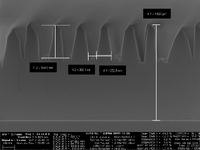

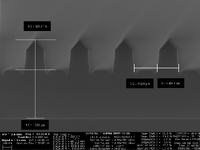

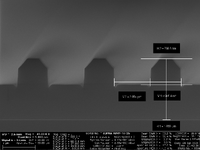

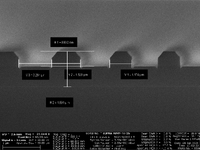

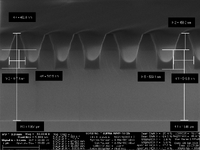

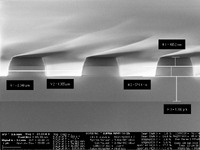

Profile pictures of some tests - April 2023

Even in the cases with the resist strip (plasma asher 2 processing for 10/15min), there are some traces of resist left on the edges of the features.

Also, it´s noticeable that the feature profile is trenching, being more evident with faster etch rates.

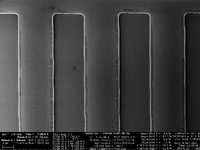

| CF4ICP 45 CF4 + resist strip

|

CF4ICP 45 CF4 / 10 H2 + resist strip

|

CF4ICP 35 CF4/ 10 H2

|

CF4lowCP 45 CF4/ 10 H2

|

CF4lowCP 45 CF4/ 0 H2 + resist strip

|

CF4lowCP 35 CF4/ 10 H2 + resist strip

|

CF4lowCP 22.5 CF4/ 22.5 H2 + resist strip

|

|

|

|

|

|

|

|

Recipes and results - CF4 / H2 tests

| Recipe

|

Recipe parameters

|

Process time

|

Date

|

SEM picture

|

Etch rate in SiO2

|

Etch rate in resist

(AZ5214E inverse)

|

Selectivity

(SiO2:resist)

|

| CF4ICP 22.5/22.5

|

CF4= 22.5 sccm

H2= 22.5 sccm

Coil= 800W

Platen= 15W

Press= 2.5mTorr

Temp= 20°C

|

11:00 min

|

11/09/2023

|

|

68 nm/min

+/- 8.5%

|

60,2 nm/min

+/- 9%

|

1.13

|

| CF4ICP 35/10

|

CF4= 35 sccm

H2= 10 sccm

Coil= 800W

Platen= 15W

Press= 2.5mTorr

Temp= 20°C

|

08:00 min

|

March 2023

|

|

69 nm/min

+/- 11.1%

|

77,1 nm/min

+/- 9.4%

|

0.9

|

| CF4ICP 45/0

|

CF4= 45 sccm

H2= 0 sccm

Coil= 800W

Platen= 15W

Press= 2.5mTorr

Temp= 20°C

|

08:00 min

|

March 2023

|

|

71.4 nm/min

+/- 10.3%

|

96,5 nm/min

+/- 6.0%

|

0.74

|

| CF4ICP 45/10

|

CF4= 45 sccm

H2= 10 sccm

Coil= 800W

Platen= 15W

Press= 2.5mTorr

Temp= 20°C

|

08:00 min

|

March 2023

|

|

67.8 nm/min

+/- 14.9%

|

88,86 nm/min

+/- 4.8%

|

0.76

|

| CF4lowCP 22.5/22.5

|

CF4= 22.5 sccm

H2= 22.5 sccm

Coil= 150W

Platen= 25W

Press= 2.5mTorr

Temp= 20°C

|

20:00 min

|

Sept 2023

|

|

23.8 nm/min

+/- 11%

|

20,6 nm/min

+/- 19.4%

|

1.16

|

| CF4lowCP 35/10

|

CF4= 35 sccm

H2= 10 sccm

Coil= 150W

Platen= 25W

Press= 2.5mTorr

Temp= 20°C

|

10:00 min

|

Feb 2023

|

|

22.65 nm/min

+/- 10.2%

|

35.9 nm/min

+/- 10.1%

|

0.63

|

| CF4lowCP 45/0

|

CF4= 45 sccm

H2= 0 sccm

Coil= 150W

Platen= 25W

Press= 2.5mTorr

Temp= 20°C

|

10:00 min

|

Feb 2023

|

|

24.9 nm/min

+/- 10.1%

|

52,3 nm/min

+/- 7.1%

|

0.47

|

| CF4lowCP 45/10

|

CF4= 45 sccm

H2= 10 sccm

Coil= 150W

Platen= 25W

Press= 2.5mTorr

Temp= 20°C

|

10:00 min

|

Feb 2023

|

|

29,4 nm/min

+/- 13.7%

|

100,6 nm/min

+/- 16.5%

|

0.29

|

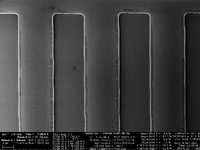

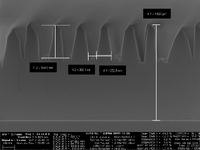

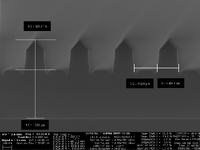

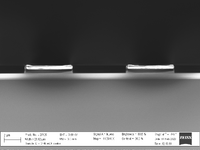

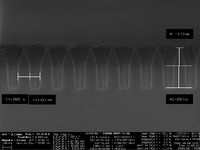

Recent results - CF4 / H2 tests

The following results were processed on chips bonded to a 100mm wafer. They were patterned with 915 UVN resist (DUV negative) and 65nm of BARC. The SiO2 layer was 2um (deposited on the C1 furnace).

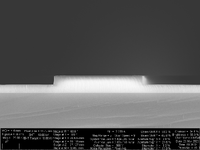

| CF4ICP @ 30W platen, 8min

|

| Values

|

SEM pictures

|

Comments

|

| Structure size (nm)

|

structure pitch (nm)

|

SiO2 ER (nm/min)

|

Resist ER (nm/min)

|

Selectivity SiO2/resist

|

|

|

| 250

|

500

|

69.36

|

114.38

|

0.61

|

|

Across the sample, the resist was fully etched away

|

| 500

|

1000

|

87.04

|

114.38

|

0.76

|

|

|

| 1000

|

2000

|

98.83

|

114.38

|

0.86

|

|

|

| 2000

|

4000

|

100.03

|

114.38

|

0.87

|

|

|

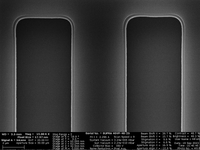

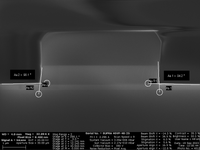

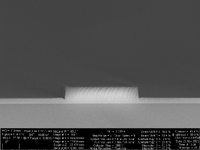

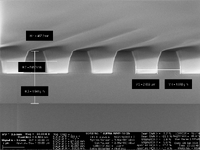

| CF4lowCP @ 45W platen, 15min

|

| Values

|

SEM pictures

|

Comments

|

| Structure size (nm)

|

structure pitch (nm)

|

SiO2 ER (nm/min)

|

Resist ER (nm/min)

|

Selectivity SiO2/resist

|

|

|

| 250

|

500

|

33.54

|

33.45

|

1.0

|

|

there was visible redeposition across smaller structures

|

| 500

|

1000

|

35.94

|

30.45

|

1.18

|

|

|

| 1000

|

2000

|

36.54

|

29.85

|

1.22

|

|

|

| 2000

|

4000

|

38.09

|

28.65

|

1.33

|

|

|