Specific Process Knowledge/Thin film deposition/Deposition of Aluminium/Thermal deposition of Al

Feedback to this page: click here

All text on this page by DTU Nanolab staff

Thermal evaporation of Aluminum

We recommend depositing a thin layer of thermally evaporated aluminum on top of e-beam resist before e-beam lithography. It is also possible to use Cr, see more info here. The advantage of Al is that it can be removed simultaneously with the e-beam resist. However Cr may allow even better resolution of the lithography.

For deposition onto the unexposed e-beam resist, you need to use thermal evaporation, since e-beam resist naturally can be exposed by e-beam evaporation and can be damaged by sputtering.

At DTU Nanolab the only deposition system for this as of 2025 is the Thermal Evaporator. Quality control data is found in the bottom section of this page.

Uniformity of Al films in the thermal evaporator

You can find some info about the uniformity of Al films deposited under different conditions in the evaporator in this document, as well as particle count for one particular evaporation: File:thermal evap uniformity data.pptx

Most of the information is from before we implemented rotation in the thermal evaporator and compares performance to our former evaporation option in the Wordentec deposition system. The last slide shows results with rotation and various holders.

Time requirements for Al deposition (approx.)

- Vent the chamber (3 min)

- Loading samples and adding Al pellets to the crucible as necessary (5 min)

- Pump down (15-25 min)

- Run the process (soaking/ramping 7 minutes plus time for the deposition rate to stabilize after opening the source shutter, time for the deposition itself and about 1 minute for running down the power afterwards). The deposition rate is 0.5-2 Å/s.

In total set aside at least 45 min PLUS time for the deposition itself.

Roughness of thermally evaporated aluminium

A study by AFM was performed to examine Al films deposited with thermal evaporation in the now decommissioned deposition system called the Wordentec. See details here.

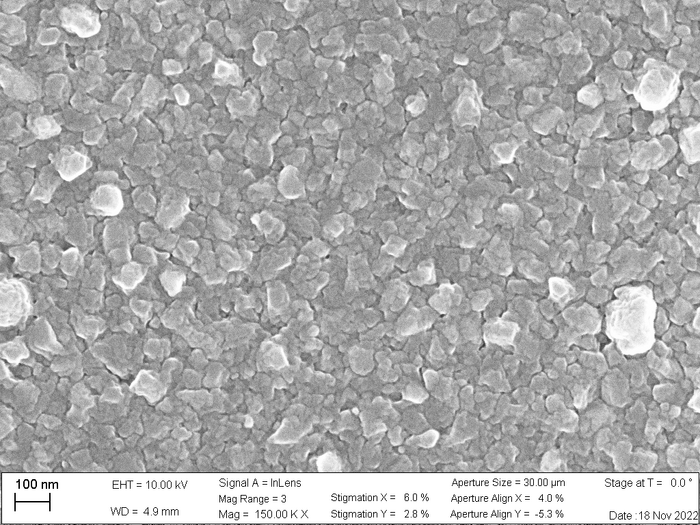

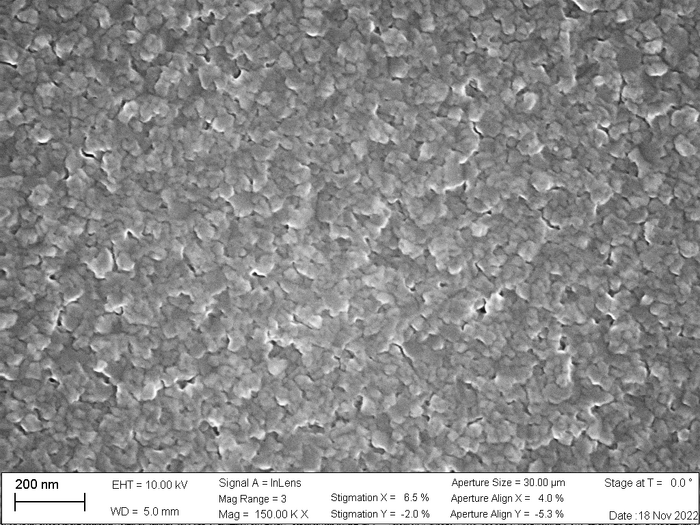

Morphology of Al films from two different thermal evaporation systems

The images below compare two films from the Lesker Thermal Evaporator and the Wordentec. The difference in grain size may be due to the shorter distance between source and substrate in the Thermal Evaporator compared to the Wordentec, which would lead to a hotter substrate in the Thermal evaporator, promoting grain growth.

Quality control (QC) of Al evaporation on the thermal evaporator

| Quality control (QC) for the Thermal evaporator | ||||||||||||||||||

Thicknesses are measured in 5 points with one of the stylus profilers (normally the DektakXT). |