Specific Process Knowledge/Thin film deposition/ALD Picosun R200/ZnO deposition using ALD/Obsolete

This page is written by DTU Nanolab internal

This page presents outdated information! Such a hardware configuration is no longer in use.

The ALD window for deposition of zinc oxide (ZnO) ranges from 100 oC to 250 oC. Several investigation techniques have been employed for characterizing ZnO. Additionally, more information on ZnO can be found on a page about Al-doped ZnO (AZO)

All results shown on this page have been obtained using the "ZnOT" recipe on new Si(100) wafers with native oxide:

ZnO ALD deposition

Evgeniy Shkondin, DTU Nanolab (former Danchip), 2014-2016.

ZnO standard recipe

Recipe: ZnOT

Maximum deposition thickness: 100 nm

Temperature: 100 oC - 250 oC

| DEZ* | DEZ | H2O | H2O | |

|---|---|---|---|---|

| Nitrogen flow | 150 sccm | 150 sccm | 200 sccm | 200 sccm |

| Pulse time | 0.1 s | 0.1 s | 0.1 s | 0.1 s |

| Purge time | 0.5 s | 20.0 s | 0.5 s | 20.0 s |

DEZ is diethylzinc Zn(CH2CH3)2 or ZnEt2

ZnO deposition rates and uniformity

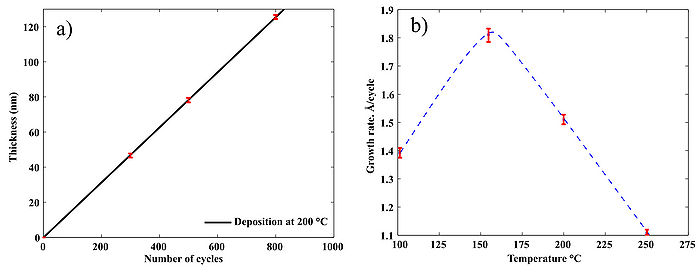

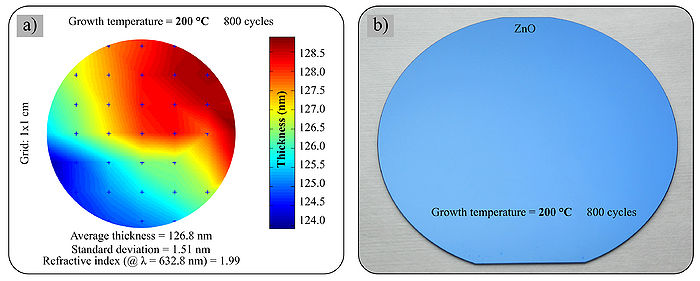

The deposition rate for ZnO depends on the temperature, see the ALD-window graph below. The uniformity, thickness, refractive index has been obtained using Ellipsometer VASE.

-

Figure 1. a) Linear growth (~0.15 nm/cycles) @ 200 oC. b) ALD-window for ZnO deposition.

-

Figure 2. a) Typical uniformity profile across 100mm Si wafer based on 49 mesurement points. b) Photography of the prepared wafer.

ZnO XPS investigation for elemental trace analysis and deposition on high aspect ratio structures

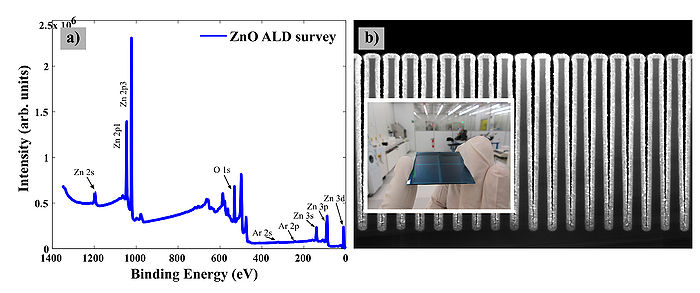

XPS profile for ZnO has been obtained using XPS K-Alpha. ZnO samples reveals (see Figure 3a) chemically high quality films with no observable contaminations in temperature range 100 - 250 oC.

The recipe is good for deposition on very high aspect ratio structures (with aspect ratio more than 1:20) such as deep trenches, pillars, pores etc. ZnOT recipe can also be used for deposition on polymers at low temperatures (80-120 oC).

-

Figure 3. a) XPS survey scan b) SEM images of ZnO deposited on a Si trenches at 200 oC temperature and 700 cycles. Trenches prepered using DRIE-Pegasus. Inset image shows the photography of the sample.

Evgeniy Shkondin, DTU Nanolab (former Danchip), 2014-2016.