Specific Process Knowledge/Thin film deposition/ALD2 (PEALD)/AlN deposition using ALD2/Acceptance test AlN

Feedback to this page: click here

This page is written by DTU Nanolab internal

AlN with N2 plasma

The test was done with 300 cycles at 350 °C where the growth rate was measured to be 0.0625 nm/cycle.

| TMA | N2 plasma | |

|---|---|---|

| Nitrogen flow | 150 sccm | 100 sccm |

| Pulse time | 0.1 s | 21.0 s |

| Purge time | 4.0 s | 4.0 s |

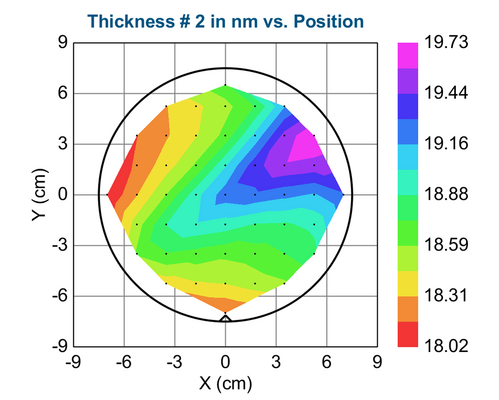

Uniformity profile across 150 mm Si wafer based on 49 measurement points measured with ellipsometer. The values for the grown oxide thickness can be seen in the table below.

| Parameter | Average | Min. | Max. | Std.Dev | %Range |

|---|---|---|---|---|---|

| Thickness (nm) | 18.77 | 18.02 | 19.73 | 0.41 | 9.0619 |

Pernille Voss Larsen, Mikkel Dysseholm Mar and Tanja Amport, DTU Nanolab, 2016-2017.

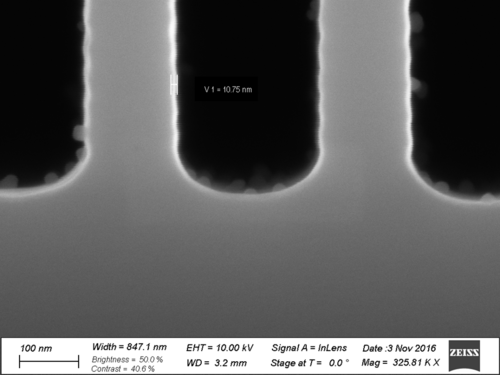

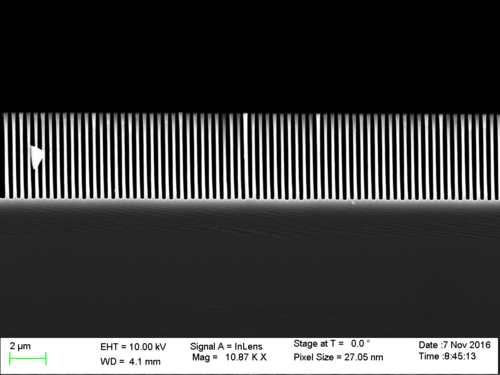

AlN with N2 plasma on trenches

The test was done with 1000 cycles at 350 °C.

| TMA | N2 plasma | |

|---|---|---|

| Nitrogen flow | 150 sccm | 100 sccm |

| Pulse time | 0.1 s | 26.0 s |

| Purge time | 4.0 s | 15.0 s |

Additionally the picoflow was used for the TMA precursor.

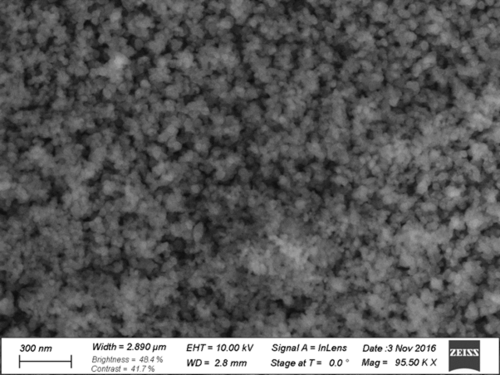

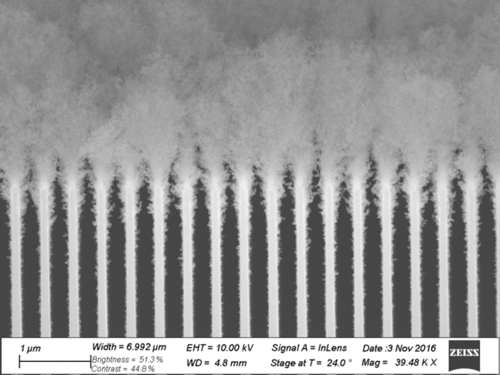

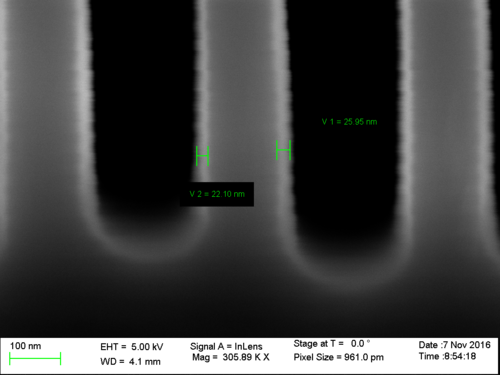

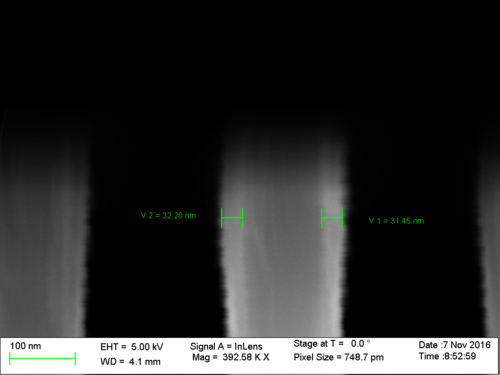

As the SEM images above show only a thin layer of AlN could be deposited at the bottom of the trenches. On the top the growth was significantly higher which lead to a tree like growth. Whereas in the images below no picoflow was used with 500 cycles and the same other parameters as in the run shown above. Without the picoflow a more homogeneous coverage could be obtained and an average growth rate of 0,05585 nm/cycle was measured.

Pernille Voss Larsen, Mikkel Dysseholm Mar and Tanja Amport, DTU Nanolab, 2016-2017.