Specific Process Knowledge/Thermal Process/Pyrolysis/Pyrolysis with Multipurpose Anneal Furnace

Feedback to this page: click here

This page is written by DTU Nanolab internal

Pyrolysis Recipes

Because the properties of the final carbon are largely depending on the pyrolysis process as well as the polymer precusors, each parameter has a different influence. By modifying those parameters, the properties of pyrolytic carbon can be tailored. The number of steps, the maximum temperature of each step, the heating rate, the dwell time at the maximum temperature and the gas composition inside the furnace are the parameters that can be changed to control the properties of pyrolytic carbon. At DTU Nanolab, the polymer precusor mostly is SU-8 negative photoresist and high temperature 3D printing resin. Depend on the designed properties of pyrolytic carbon material, pyrolysis process will be optimized.

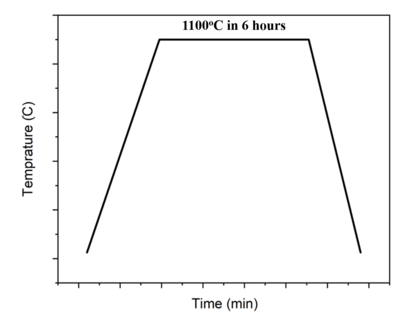

Optimized Recipe for the conductivity of pyrolytic carbon

For using pyrolytic carbon as a working electrode for electrochemical sensor, the conductivity of the pyrolytic carbon must be maximized. The main goal of this recipe is to obtain the carbon material with highest conductivity as possible. The conductivity is measured by probe station with 4 points probe method.

Recipe: ""

| Parameter | Value |

|---|---|

| Precusor | SU-8 |

| Number of step | 1 |

| Final Temperature | 1100oC |

| Ramping Rate | 2oC per minute |

| Annealing time at final temperature | 6 hours |

| Gas | 20 sccm N2 |

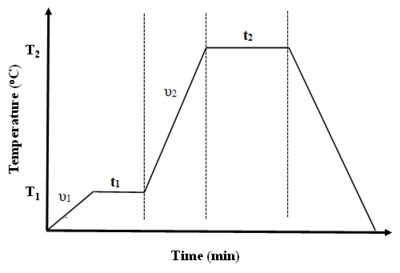

Optimized Recipe for the stress of pyrolytic carbon

Recipe for maximize the tensile stress of pyrolytic carbon material. The stress is measured by the DektakXTA by thin film stress method.

Recipe: "Long_optimized"

| Parameter | Value |

|---|---|

| Precusor | SU-8 |

| Number of step | 2 |

| First step Temperature | 200oC |

| First step Anneal time | 30 minutes |

| First step Ramping Rate | 2oC per minute |

| Final temperature | 700oC |

| Ramping rate to final temperature | 30oC per minute |

| Annealing time at final temperature | 10 minutes |

| Gas | 20 sccm N2 |

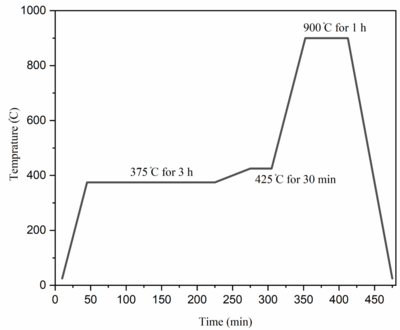

Optimized Recipe for the porous structure of pyrolytic carbon

This recipe is applied for High temperature 3D printing resin in order to obtain the high porous structure of pyrolytic carbon material. The structure is characterized by SEM image.

Recipe: ""

| Parameter | Value |

|---|---|

| Precusor | High temperature 3D printing resin |

| Number of step | 3 |

| First step Temperature | 375oC |

| First step Anneal time | 3 hours |

| First step Ramping Rate | 2oC per minute |

| Second step Temperature | 425oC |

| Second step Anneal time | 30 minutes |

| Second step Ramping Rate | 1oC per minute |

| Final temperature | 900oC |

| Ramping rate to final temperature | 2oC per minute |

| Annealing time at final temperature | 1 hour |

| Gas | 20 sccm N2 |