Specific Process Knowledge/Etch/Etching of Silicon Oxide/SiO2 etch using AOE/Standard recipe with resist mask/Variations over SiO2 mres

< Specific Process Knowledge | Etch | Etching of Silicon Oxide | SiO2 etch using AOE | Standard recipe with resist mask

Jump to navigation

Jump to search

Feedback to this page: click here

Experiments done with the TDESC electrode that we installed in 2010 (by Roy Cork and Berit Herstrøm @Nanolab)

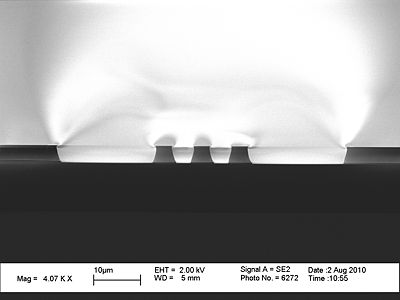

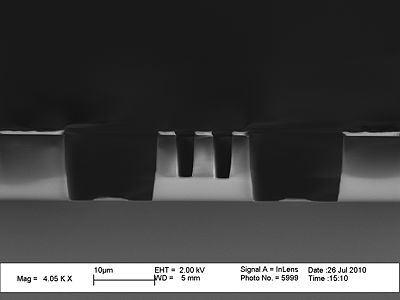

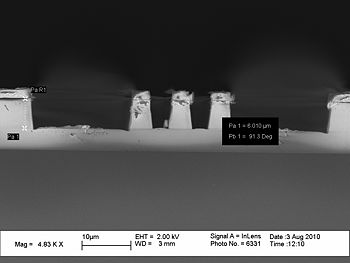

After changing the electrode to the TDESC type we got a lot of issues with trenching during the acceptance test. After doing a lot of experiments and optimization it turned out that this was probably do to a bad resist profile. We used a negative resist and the problems were gone. Here I show some of the results we got during this optimization.

Conclusions

- Very important to have a good resist profile before etch.

- Trenching and rounded corners can be controlled with coil and platen power.

- H2 does not have much influence (expected to have influence on the SiO2:Si selectivity)

- C4F8 flow has a influence on the profile and on the aspect ratio dependent etch - keep it low.

- Pressure does not show much influence

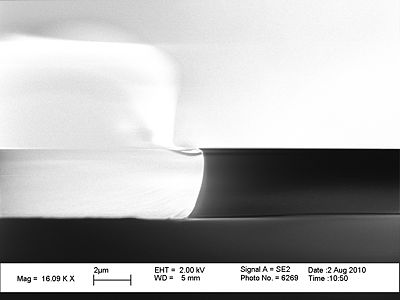

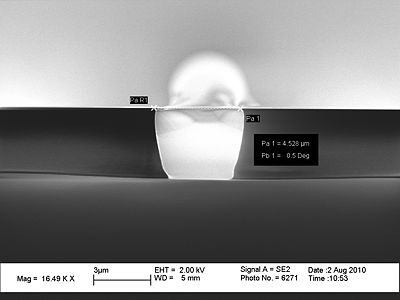

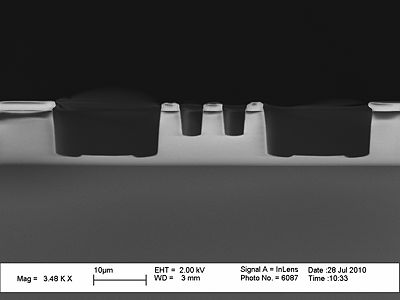

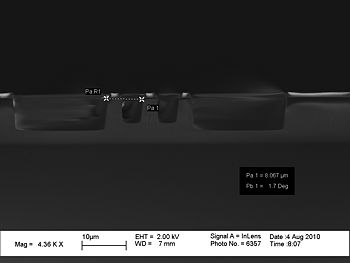

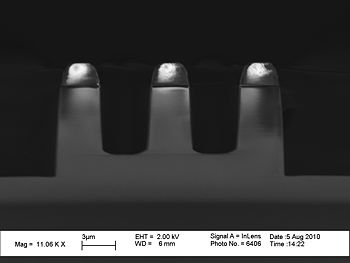

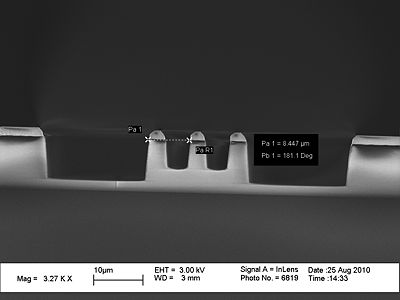

- This is the resist mask profile before etching

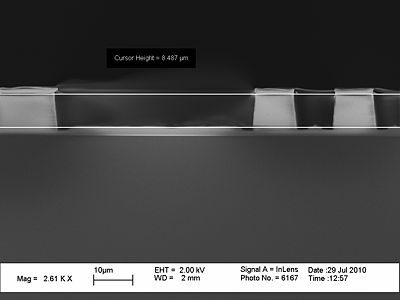

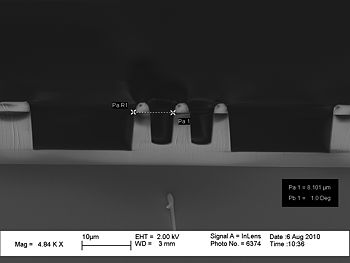

- Variation of Platen power at coil power 1300W, no H2 and C4F8 at 10sccm

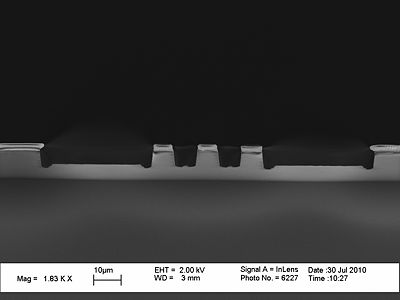

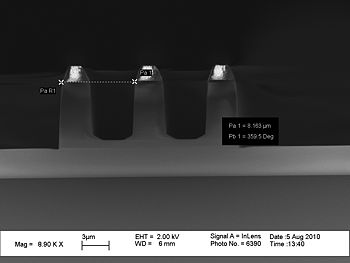

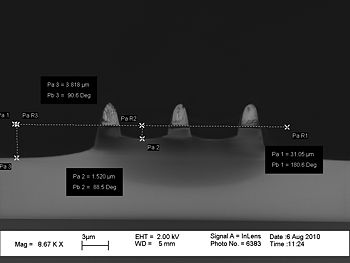

- Variation of Platen power and He flow at coil power 1600W, no H2 and C4F8 at 10sccm

- Variation of Platen power and He flow at coil power 1000W, no H2 and C4F8 at 10sccm

- Variation of He flow and pressure at coil power 1000W and platen power 180W (He: 174sccm - pressure: 4mTorr), no H2 and C4F8 at 10sccm

- Variation of C4F8 flow at coil power 1000W and platen power 180W, He: 300sccm, pressure: 4mTorr), no H2

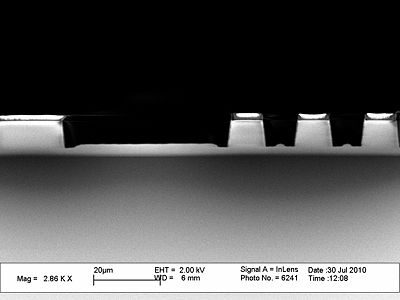

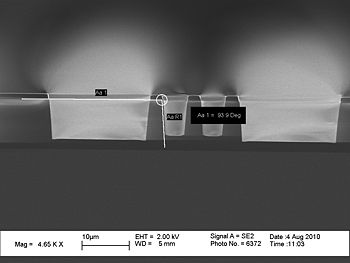

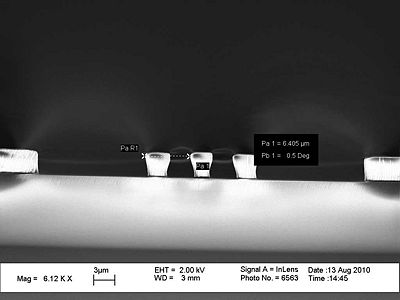

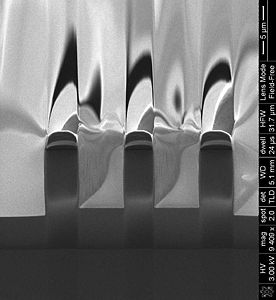

- Negative mask