Feedback to this page: click here

Here are presented some images of etches using the recipe SiO2_res

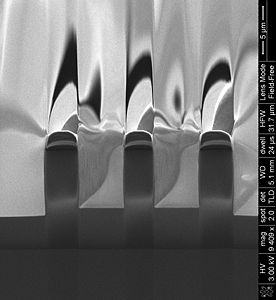

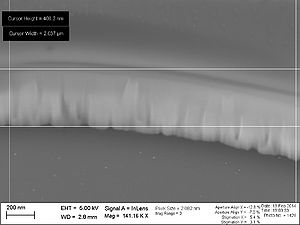

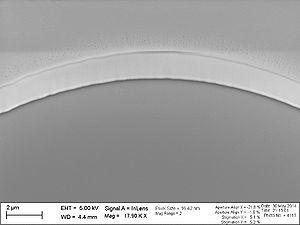

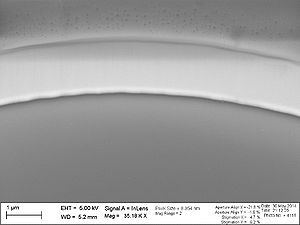

Profile of 1-10µm deep etch + resist profile

by Berit Herstrøm (BGHE) from nanolab

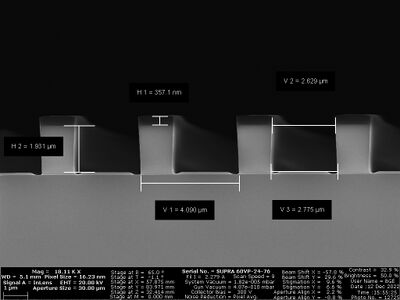

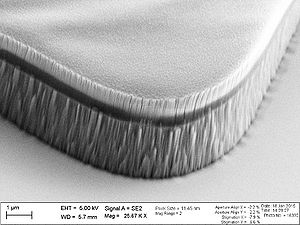

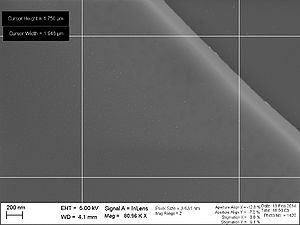

- Old AZ5214E resist (negative - I think), etched for 10 min with SiO2_res at 0 dg. with spacers 30 mm

- January 2018 by BGHE, SiO2_res@0degrees, etch time: 4 min, 0mm spacers

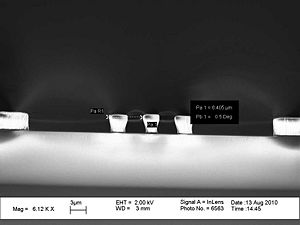

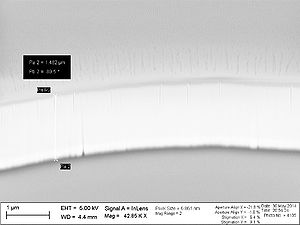

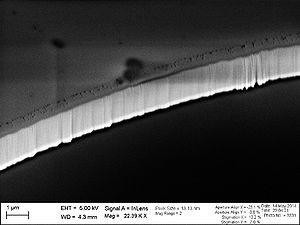

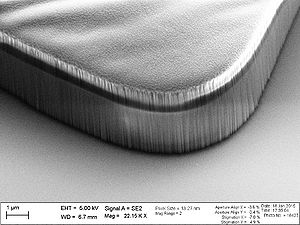

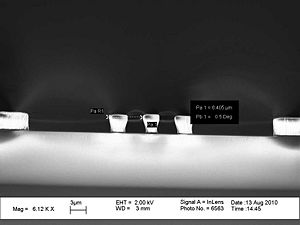

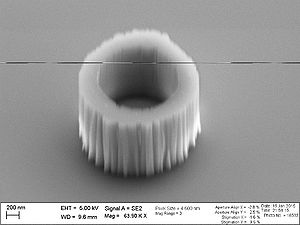

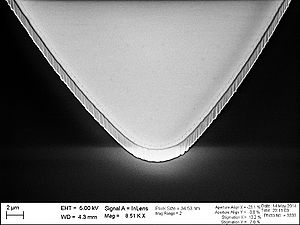

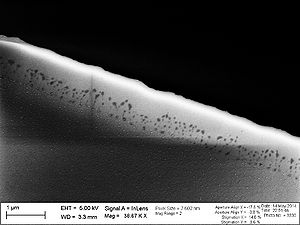

Process date: September 2010 Recipe: m_res_ny@0degrees Etch time: 30 min Mask: AZ resist 4 µm thick negative process Viewed in profile - charging is seen in the top, by BGHE |

Process date: September 2010 This is showing the resist profile before AOE etch Mask: AZ resist 4 µm thick negative process, by BGHE |

Resist mask effected by m_res_ny

by bghe@nanolab

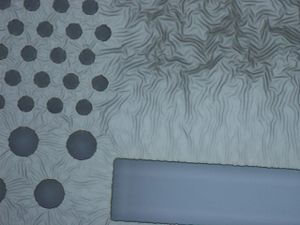

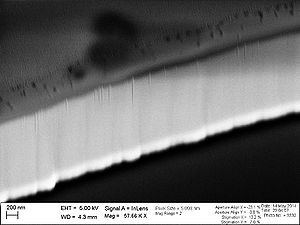

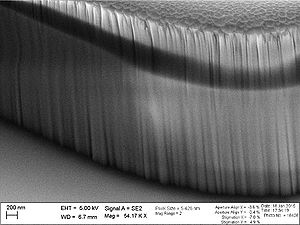

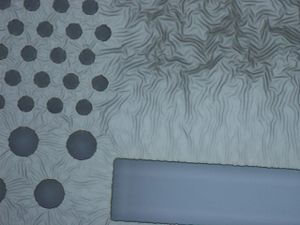

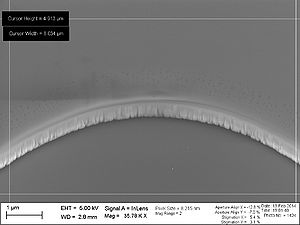

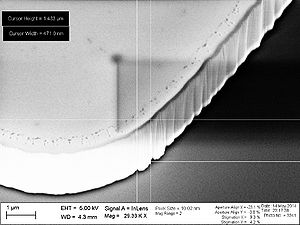

Process date: May 2011 Recipe: m_res_ny@0degrees Process time: 30 min Mask: AZ resist 4 µm. Explanation: the surface of the resist gets UV hardened by the plasma. Later the resist gets hot and starts floating - some liquid evaporates. When the wafer cools again the resist shrinks but the hardend surface cannot shrink so it contracts instread giving rise to these creases/folds. |

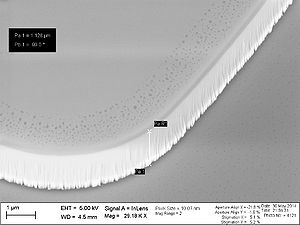

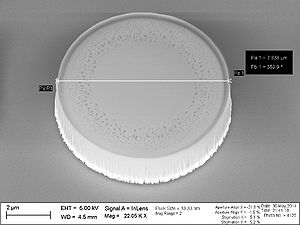

Resist mask baked at 150dg effected by m_res_ny

by bghe@nanolab

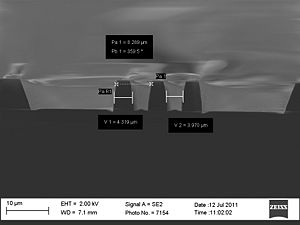

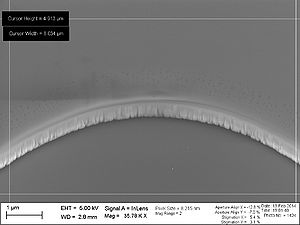

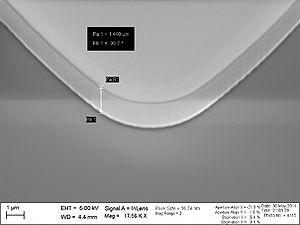

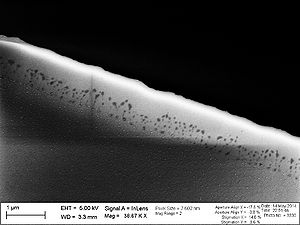

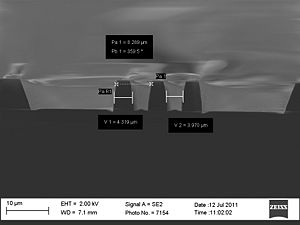

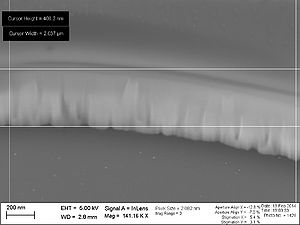

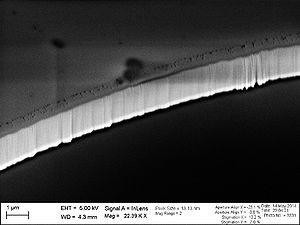

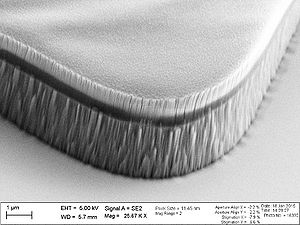

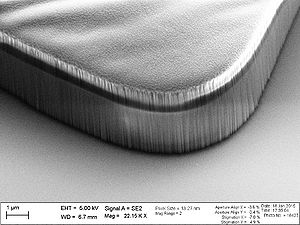

Process date: July 2011 Recipe: m_res_ny@0degrees Process time: 30 min Mask: AZ resist 4 µm thick The wafer was preheated to 150dg for 5min. Explanation:The pretreatning makes the resist float and liquid evaporates. Then during the plasma processing there is no more liquid that evaporates and the surface do not contract during cool off. This gives more smooth edges between the wafer and the resist but the profile is more round giving more angled profiles of the oxide etch. |

Process date: July 2011 Recipe: m_res_ny@0degrees Process time: 30 min Mask: AZ resist 4 µm thick The wafer wafer preheated to 150dg for 5min. Explanation:The pretreatning makes the resist float and liquid evaporates. Then during the plasma processing there is no more liquid that evaporates and the surface do not contract during cool off. This gives more smooth edges between the wafer and the resist but the profile is more round giving more angled profiles of the oxide etch. |

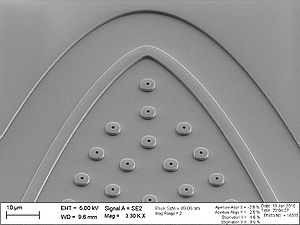

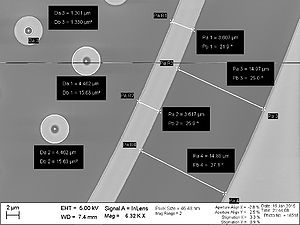

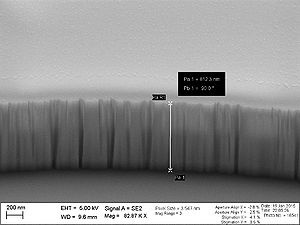

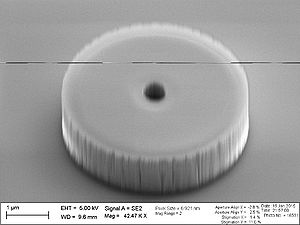

Etching of 1.0 µm SiO2 by 15 min m_res_ny: Artefacts from Lithography

by Frederik Stöhr @danchip

General Description

- Process date: Jan 2015

- Recipe: m_res_ny@0degrees

- Process time: 15 min

- Substrate: 525 µm Si + 1 µm thermal silicon oxide + ~50 nm BARC (anti reflection coating, which promotes adhesion)

- Mask: [XOP12] AZ5214E positive resist 1.5 µm thick (6-inch aligner 3 sec exposure, 60 sec developer)

- Etch Load (Total Exposed SiO2): ~ 10 %

- Post process: O2 Plasma Ashing 10 min

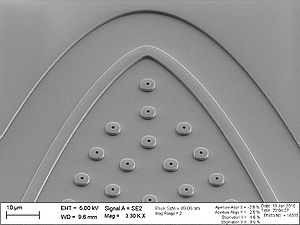

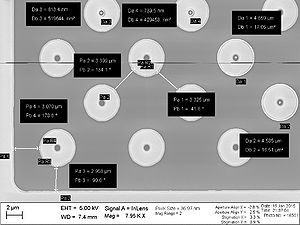

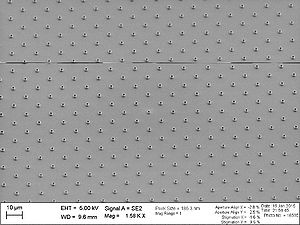

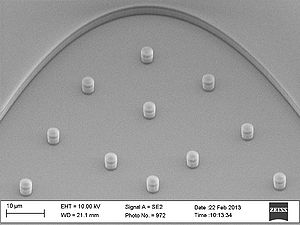

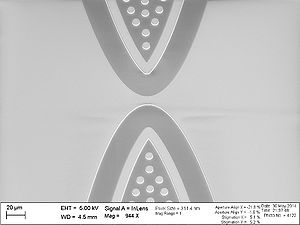

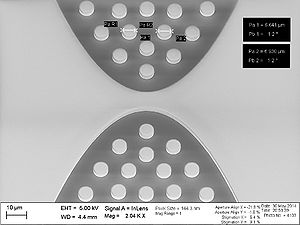

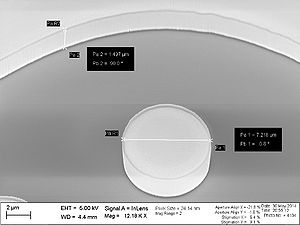

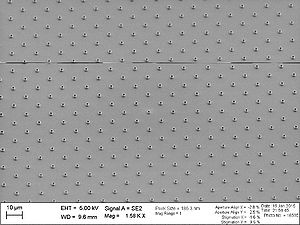

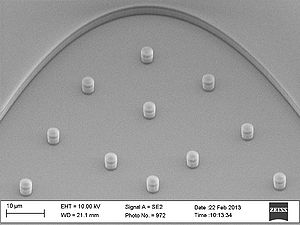

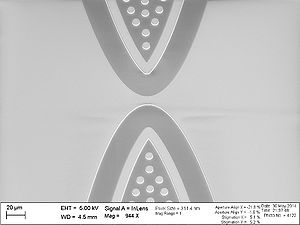

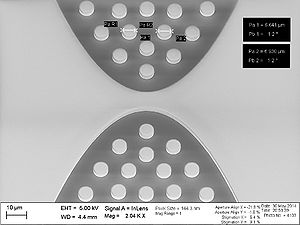

The view tilt angle is 40 degrees. According to the original mask design the dots should not be hollow. Nevertheless, during lithography interference effects must have caused the center of the dots to be exposed. Obviously, this artefact is so pronounced that it is also transferred in the subsequent structuring of the silicon oxide. |

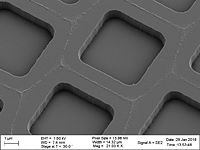

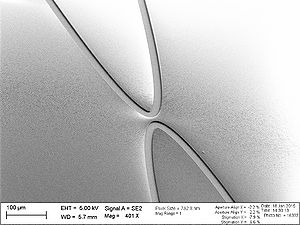

Bird view of nominal 5 µm dots and a 4 µm line. |

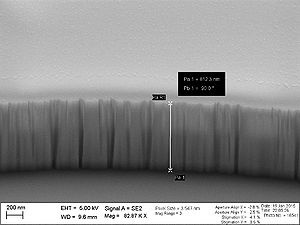

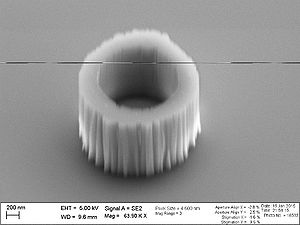

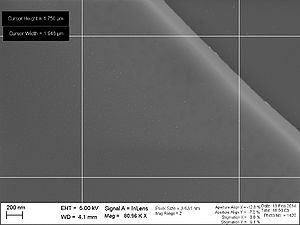

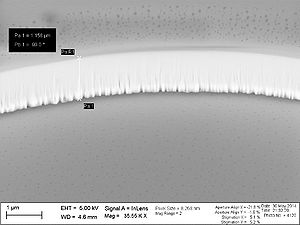

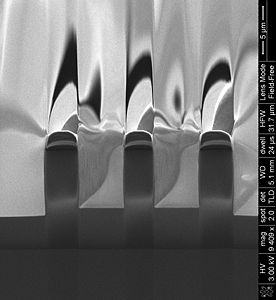

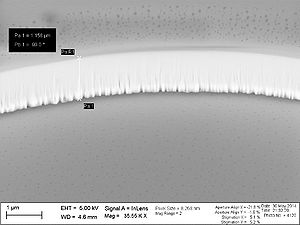

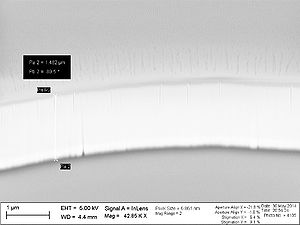

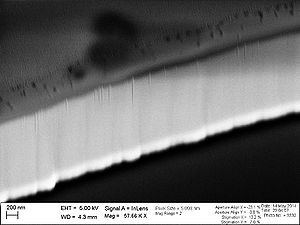

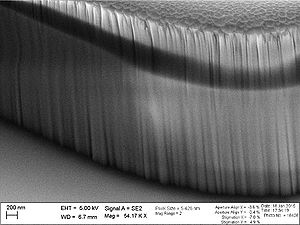

The view tilt angle is 40 degrees. A side wall of etched silicon oxide. It shows vertical striations. The silicon substrate was over-etched by ~200 nm. |

|

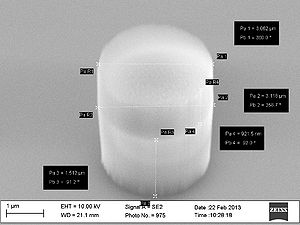

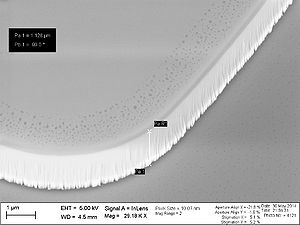

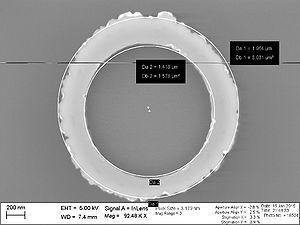

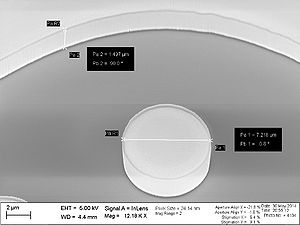

The view tilt angle is 40 degrees. A dot with nominal 5 µm diameter and an inner hole of 1.3 µm diameter. |

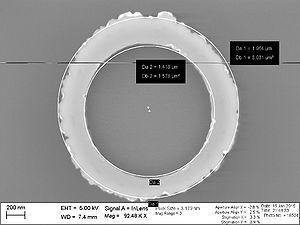

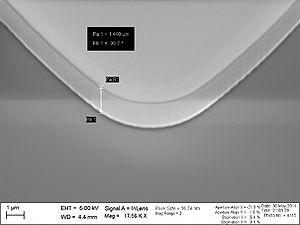

The view tilt angle is 40 degrees. A hollow dot with nominal 3 µm diameter. The width of the ring is ~500 nm. |

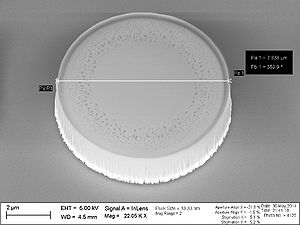

Bird view of a hollow dot with nominal 3 µm diameter. The width of the ring is ~500 nm. |

The view tilt angle is 40 degrees. Zoom-out showing a field full of hollow dots with nominal 3 µm diameter. |

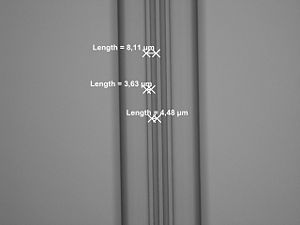

Etching of 1.1 µm SiO2 by 10 min m_res_ny: Corrugated sidewall

by Frederik Stöhr @danchip

General Description

- Process date: Feb 2014

- Recipe: m_res_ny@0degrees

- Process time: 5:30 min

- Substrate: 525 µm Si + 1.1 µm thermal silicon oxide + HMDS (adhesion promoter)

- Mask: [XOP3] AZ positive resist 1.5 µm thick (6-inch aligner 3 sec exposure, 60 sec developer)

- Etch Load (Total Exposed SiO2): ~ 10 %

- Post process: O2 Plasma Ashing 10 min

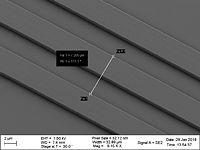

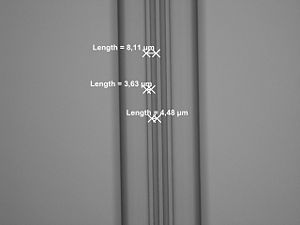

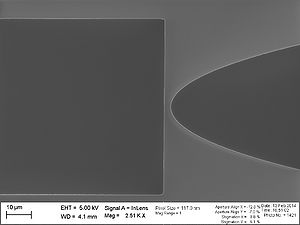

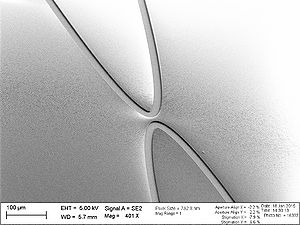

Bird View. Dark area is Silicon. Bright area is Silicon Dioxide. The edges are nicely defined, though corrugated on the 100 nm scale. |

Close up. Bird View. Dark area is Silicon. Bright area is Silicon Dioxide. Residues of the SiO2 etching are apperent on top of the SiO2, i.e. particles a few nanometers in diameter. Most probably it is sputtered and redopsited Silicon Dioxide, but not confirmed. Attempts to remove them in 7-Up or HCl failed. |

Tilt angle 20 degree. Close up. Bird View. Dark area is Silicon. Bright area is Silicon Dioxide. The Silicon Dioxide sidewall is corrugated. |

Tilt angle 20 degree. Close up. Bird View. Dark area is Silicon. Bright area is Silicon Dioxide. The Silicon Dioxide sidewall is corrugated. |

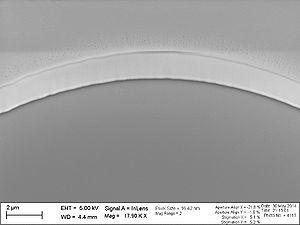

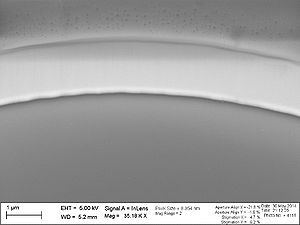

Etching of 2.1 µm SiO2 by 10 min m_res_ny: PR mask shape

by Frederik Stöhr @danchip

General Description

- Process date: Feb 2013

- Recipe: m_res_ny@0degrees

- Process time: 10 min

- Mask: [XOP2] AZ5214E positive resist 2.2 µm thick (6-inch aligner 4 sec exposure, 70 sec developer)

- Etch Load (Total Exposed SiO2): ~ 10 %

- Post process: None

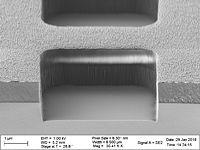

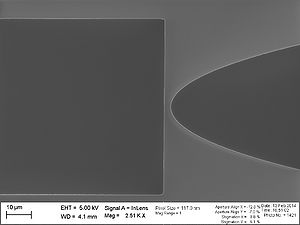

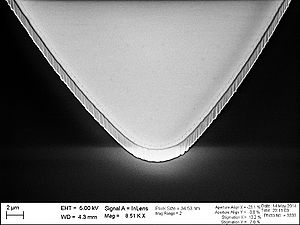

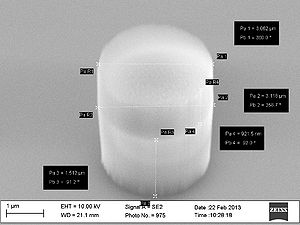

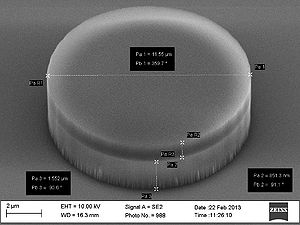

The view tilt angle is 45°. The dark area is Silicon. The bright area is Silicon Oxide. The pattern is composed of dots with nominal 4 µm diameter. The resist mask is still intact. |

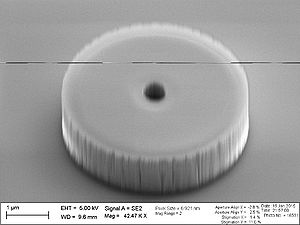

The view tilt angle is 45°. A nominal 4 µm diameter dot. The resist mask is still intact. The dot is nicely defined, the sidewalls are straight and smooth with minor striations at the lower 500 nm. |

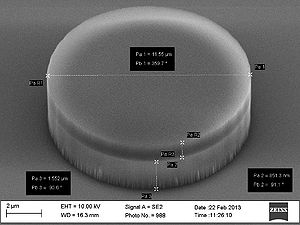

The view tilt angle is 45°. A nominal 12 µm diameter dot. The resist mask is still intact. The dot is nicely defined, the sidewalls are straight and smooth with minor striations at the lower 500 nm. |

Etching of 2.1 µm SiO2 by 12 min m_res_ny: Etch residues

by Frederik Stöhr @danchip

General Description

- Process date: April 2014

- Recipe: m_res_ny@0degrees

- Process time: 12 min

- Substrate: [XOP5] 525 µm Si + 2 µm thermal silicon oxide + HMDS (adhesion promoter)

- Mask: AZ5214E positive resist 2.2 µm thick (6-inch aligner 4 sec exposure, 70 sec developer)

- Etch Load (Total Exposed SiO2): ~ 10 %

- Post process: O2 Plasma Ashing 10 min

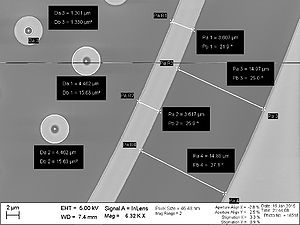

The view tilt angle is 30°. The dark area is Silicon. The bright area is Silicon Oxide. The pattern is composed of ~10 µm wide lines and dots with ~8 µm diamter. |

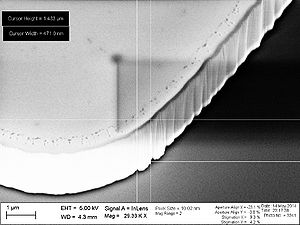

Close-up of the SiO2 sidewall. It is highly corrugated. On the Silicon Oxide as well as on the Silicon surface small particles are apparent, which are most likely redeposited residues from the etching. The view tilt angle is 30°. |

Close-up of the SiO2 sidewall. On the SiO2 and Si surface etch residues are apparent. The view tilt angle is 30°. |

Close-up of a SiO2 dot. The view tilt angle is 30°. |

Etching of 2.8 µm SiO2 by m_res_ny with AZ5214E mask

by Frederik Stöhr @danchip

General Description

- Process date: May 2014

- Recipe: m_res_ny@0degrees

- Process time: 16 VS 20 min

- Substrate: 525 µm Si + 2.8 µm thermal silicon oxide + HMDS (adhesion promoter)

- Mask: AZ5214E positive resist 2.2 µm thick (6-inch aligner 4 sec exposure, 70 sec developer)

- Etch Load (Total Exposed SiO2): ~ 10 %

- Post process: O2 Plasma Ashing 10 min

Etch time = 16 min. The view tilt angle is 30°. The dark area is Silicon. The bright area is Silicon Oxide. The edges relatively smooth. |

Etch time = 16 min. The view tilt angle is 30°. The dark area is Silicon. The bright area is Silicon Oxide. The edges relatively smooth. |

Etch time = 16 min. The view tilt angle is 30°. The dark area is Silicon. The bright area is Silicon Oxide. The edges relatively smooth. |

Etch time = 20 min. The view tilt angle is 30°. The dark area is Silicon. The bright area is Silicon Oxide. The edges relatively smooth. |

Etch time = 20 min. The view tilt angle is 30°. The dark area is Silicon. The bright area is Silicon Oxide. The edges relatively smooth. |

Etch time = 20 min. The view tilt angle is 30°. The dark area is Silicon. The bright area is Silicon Oxide. The edges relatively smooth. |

Etch time = 20 min. The view tilt angle is 30°. The dark area is Silicon. The bright area is Silicon Oxide. The edges relatively smooth.. |

Etching of 2.8 µm SiO2 by m_res_ny with AZ MiR 701 mask

by Frederik Stöhr @danchip

General Description

- Process date: May 2014

- Recipe: m_res_ny@0degrees

- Process time: 15:30 min

- Substrate: 525 µm Si + 2.8 µm thermal silicon oxide + HMDS (adhesion promoter)

- Mask: [XOP6] MiR 701 positive resist 2.0 µm thick (KS aligner 29 sec exposure, TMAH Manual MiR701 60s)

- Etch Load (Total Exposed SiO2): ~ 10 %

- Post process: O2 Plasma Ashing 10 min

The view tilt angle is 30°. The dark area is Silicon. The bright area is Silicon Oxide. The edges are nicely defined, although they are corrugated on a 100 nm scale. |

The view tilt angle is 30°. The dark area is Silicon. The bright area is Silicon Oxide. The edges are nicely defined, although they are corrugated on a 100 nm scale. |

Close-up. The view tilt angle is 30°. Considerable overetching of the Silicon substrate is apparent. |

The view tilt angle is 30°. Within 1 µm form the edge the silicon oxide is covered with residues from the etching. These residues may be sputtered and redeposited silicon dioxide. It originally covered the photo resist mask, but finally remained on the silicon dioxide after mask ashing. |

The view tilt angle is 30°. Considerable overetching of the Silicon substrate is apparent. |

Top view, highlighting the residues. |

Etching of 2.2 µm SiO2 by SIO2_RES 10 min VS 15 min

by Frederik Stöhr @danchip

General Description

- Process date: Jan 2015

- Recipe: SIO2_RES@0degrees

- Process time: 10 min VS 15 min

- Substrate: 525 µm Si + 2.2 µm thermal silicon oxide + HMDS (adhesion promoter)

- Mask: [XOP8] AZ5214E positive resist 2.2 µm thick (6-inch aligner 4sec exposure, 60s developer)

- Etch Load (Total Exposed SiO2): ~ 10 %

- Post process: None

Etch time = 10 min. The view tilt angle is 45°. The photo resist mask is still intact. It is corrugated, which may be due to insufficient cooling during processing, but does not harm the integrity of the etching. |

Etch time = 10 min. The view tilt angle is 45°. Close-up of the etched sidewall. It is highly corrugated. |

Etch time = 15 min. The view tilt angle is 45°. The photo resist mask is still intact. Compared to an etch time of 10 min the sidewall is smooth, with minor vertical corrugations remaining. |

Etch time = 15 min. The view tilt angle is 45°. Close-up. Compared to an etch time of 10 min the sidewall is smooth, with minor vertical corrugations remaining. |