Feedback to this page: click here

Etching of micro structures in Aluminum oxide using the standard SiO2 recipe

by Fredrik Stöhr @DTU Danchip incl. all SEM images

Aluminum oxide (Al2O3, Alumina) can be etched with the standard recipe for silicon oxide etching. The parameters including the chuck temperature are identical to the recipe described above: SiO2_res.

The etch is probably very physical and gives redeposition, so please using a Cl2 etch on the ICP metal instead (BGHE 2015-04-17)

General Description

- Process date: Summer 2014

- Aluminum Oxide with a thickness of 50 nm has been deposited by atomic layer deposition using the respective standard recipe.

- Substrates: Blank 525 µm Silicon wafers or Silicon wafers with thermally grown Silicon Oxide prior to Alumina deposition.

- Mask: [XOP8] AZ5214E 1.5 µm thick (HMDS pretreatment, 6-inch aligner 3 sec exposure, 60 sec development).

- Etch Load (Total Exposed SiO2): ~ 5 %

- Post process: O2 Plasma Ashing 10 min

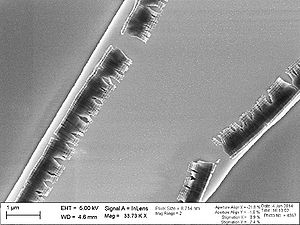

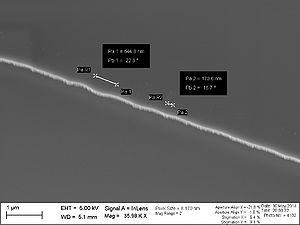

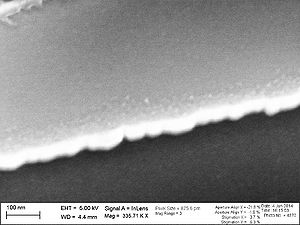

Etch time: 3 min. Substrate: Blank Si. Bird View. The dark area is Silicon. The bright area is Alumina. The black flakes stem from redeposited sputtered material and is most likely aluminum oxide, since it is almost non-volatile in the used plasma chemistry. It must have been laying on top of the photo resist mask and landed on the alumina after resist ashing. |

Etch time: 3 min. Substrate: Blank Si. Bird View. Close-up. The dark area is Silicon. The bright area is Alumina. The black flakes stem from redeposited sputtered material. |

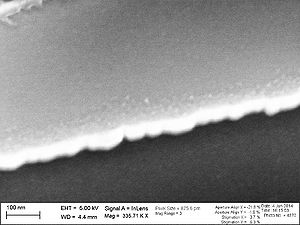

Etch time: 3 min. Substrate: Blank Si. Bird View. Close-up. The dark area is Silicon. The bright area is Alumina. |

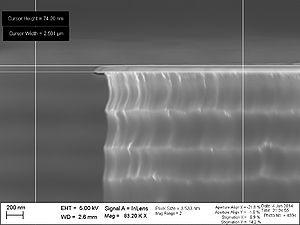

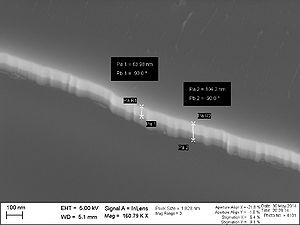

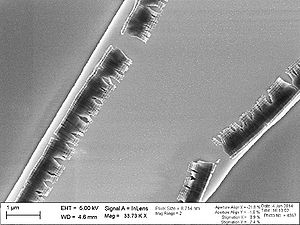

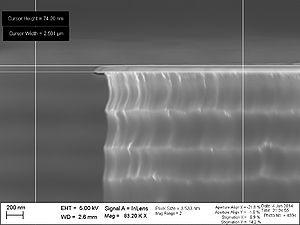

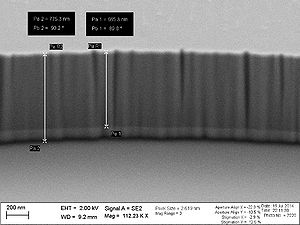

Etch time: 3 min Cross section of deep reactive ion etched silicon (DRIE Pegasus), where the structured alumina was used as a mask. Remarkably, the etch selectivity of Alumina to Silicon is >1:10000. |

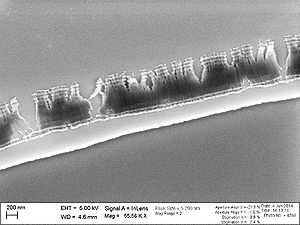

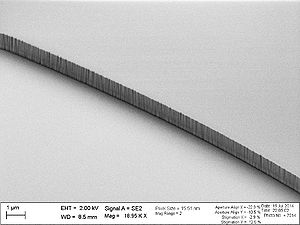

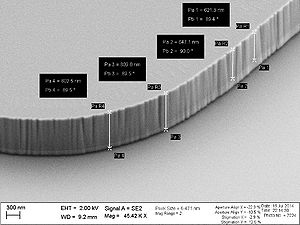

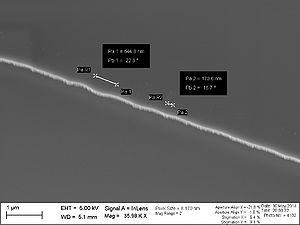

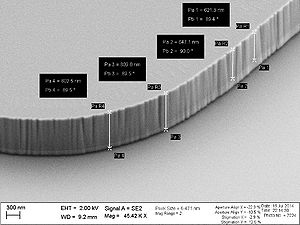

Etch time: 10 min. Substrate: Blank Si. The view tilt angle is 30°. The edge is corrugated, which is most likely to the corrugated resist mask. |

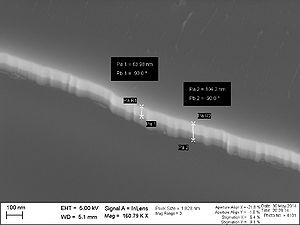

Etch time: 10 min. Substrate: Blank Si. The view tilt angle is 30°. Vertical striations and considerable over-etching of the Silicon substrate are apparent. It seems as if less material has been redeposited, which may be due to the prolonged etch time in comparison to the above. |

Etch time: 10 min. Substrate: Blank Si. The view tilt angle is 30°. Vertical striations and considerable over-etching of the Silicon substrate are apparent. It seems as if less material has been redeposited, which may be due to the prolonged etch time in comparison to the above. |

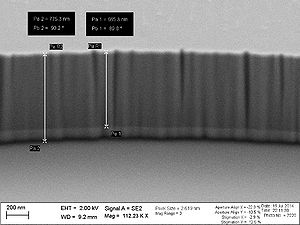

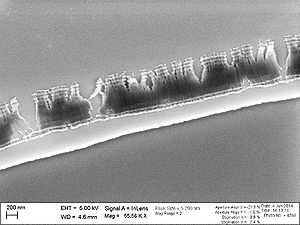

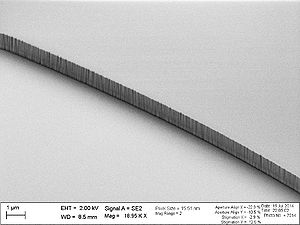

Etch time: 15 min. Substrate: Silicon with 1 µm thermally grown SiO2 The view tilt angle is 45°. Alumina and Silicon Oxide may be etched in one go. |

Etch time: 15 min. Substrate: Silicon with 1 µm thermally grown SiO2 The view tilt angle is 45°. Alumina and Silicon Oxide may be etched in one go. Considerable over-etchign of the Silicon substrate is apparent. |

Etch time: 15 min. Substrate: Silicon with 1 µm thermally grown SiO2 The view tilt angle is 45°. Alumina and Silicon Oxide may be etched in one go. Considerable over-etchign of the Silicon substrate is apparent. |