Specific Process Knowledge/Etch/Etching of Silicon Oxide/SiO2 etch using AOE/Slow etch with resist mask

Feedback to this page: click here

This page is written by Berit Herstrøm @ DTU Nanolab (BGHE) if nothing else is stated

Slow etch of SiO2 with resist as masking material - with direct clamping

This recipe can be used for slow etching of SiO2 with resist as masking material when normal clamping is possible. Normal clamping is preferred because it give the best and most repeatable cooling of the wafer.. Here are some test results presented.

| Parameter | Resist mask |

|---|---|

| Name of Recipe | SLOWSIO2 |

| Coil Power [W] | 200 |

| Platen Power [W] | 25 |

| Platen temperature [oC] | 0 |

| CF4 flow [sccm] | 20 |

| H2 flow [sccm] | 10 |

| Pressure [mTorr] | 3 |

| Results | Test on maskless wafer | Test on wafer with 50% load |

|---|---|---|

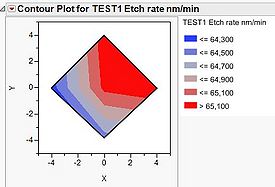

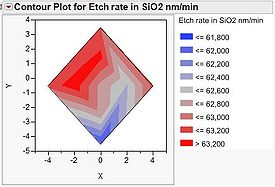

| Etch rate of thermal oxide | 64.9 nm/min (100% etch load) (22-01-2014) | 62.8 nm/min (50% etch load) (01-02-2014) |

| Selectivity to resist [:1] | No result | ~1.7 |

| Wafer uniformity (100mm) | ±0.8% (22-01-2014) | ±1.2% (01-02-2014) |

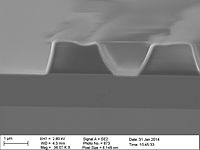

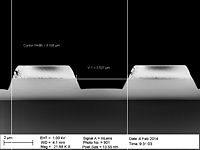

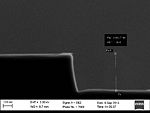

| Profile [o] | Not tested | Take a look at the images but be aware that the resist profile was not very good to start with. |

| Images (click on the image to view a larger image) | ||

| SEM images of profile | none |

|

| Comments | . | . |

Slow etch of SiO2 with resist as masking material - to be used with 150mm Si carrier wafer

The slow etch recipe for oxide etching with photo resist as masking material is called: "slowcool". The recipe has been created to order to be able to have the sample wafer on a si carrier. This means the carrier (150mm with a 102mm recess) is cooled but the wafer on top of it is not (or a small sample on a 4" wafer, as 150 mm wafers can no longer be used in the AOE /BGHE-Jan2023). This gives a problem with the wafer heating up. The recipe first has a cooling step with no power for 5 min. The etch step parameters and results so fare are as follows:

| Parameter | Resist mask |

|---|---|

| Name of recipe | SLOWSIO2 |

| Coil Power [W] | 200 |

| Platen Power [W] | 25 |

| Platen temperature [oC] | 0 |

| CF4 flow [sccm] | 20 |

| H2 flow [sccm] | 10 |

| Pressure [mTorr] | 3 |

| Typical results | nLOF Resist mask Nanolab result |

|---|---|

| Etch rate of thermal oxide | 58.5nm/min (50% etch load) (04-09-2013) |

| Selectivity to nLOF resist [:1] | ~1 (04-09-2013) |

| Wafer uniformity (100mm) | ±3.7% (04-09-2013) |

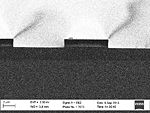

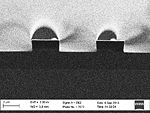

| Profile [o] | ~100degrees (04-09-2013) - probably depends on resist profile |

| Images (click on the image to view a larger image) |

|

| Comments | This nLOF negative resist has been used because it can stand more heat in the AOE chamber without getting problems with UV-hardening and evaporation of the solvent leading to a curly resist surface and very rough edges. |