Specific Process Knowledge/Back-end processing/Polymer Injection Molder/Cooling

Cooling time

When the holding time has elapsed the machine will switch to cooling time. The optimal cooling time is very process dependent, but the overall purpose is of course to give the sample enough time to cool sufficiently below the polymer's melting point (or glass transition temperature) so that the sample can be removed from the mold without deforming.

The optimal demolding temperature (temperature of the mold when the mold opens) depends on both the polymer and mold used and the structures being replicated. Generally the lower the demolding temperature the better because this makes the polymer more rigid and in some cases the shrinkage of the polymer as it cools down can also help releasing the sample from the shim. But lower demolding temperatures come with a time penalty. Generally the Luer tool is most tolerant to varying demolding condition because the 12 Luer connectors help in pulling the sample off the shim. The flat disc tool can require a little optimization for reliable demolding while the microscope slide tool can be quite challenging (especially with deep or high aspect ratio structures) because of its geometry.

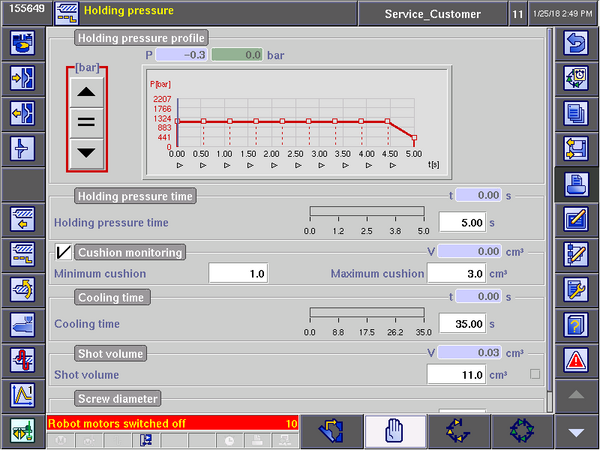

The cooling time is also found on the 'Holding pressure' screen:

- Cooling time: The cooling time (in seconds) is entered here. If you are running a variotherm process remember that mold heating and cooling water timing will greatly influence the cooling phase.