Specific Process Knowledge/Etch/Etching of Bulk Glass/AOE etching of fused silica

Appearance

Feedback to this page: click here

Comparison of masking materials and AOE processes etching fused silica

Unless otherwise stated, all content in this section was done by Berit Herstrøm, DTU Nanolab

| AZ resist mask (Recipe name: SiO2_res) | PolySi mask (Recipe name: SiO2_psi) | Cr mask (Recipe mane: SiO2_met) | |

|---|---|---|---|

| Generel description | Using a photoresist mask as etching mask is often convenient, since it takes less process steps to make than hard masks. The draw backs using resist as masking material in the AOE on glass is that glass does not transfer heat well and therefore the He cooling in the AOE does not work well on glass substrates. This makes the photoresist turn very hot during the etch and that might burn the resist. Resist also has low selectivity to glass so deep glass etch is not working well with photoresist as masking material. | Using Poly Silicon as masking material in the AOE has the advantage over photoresist in the fact that the mask can stand a higher temperature. Then a recipe with higher etch can be used. It also as a higher selectivity so it is possible to etch deeper.The draw back might be higher line width reduction but this has not been expored yet. | This recipe with a Cr mask gives the highest etch rate, but the wafer uniformity is not so good. |

| Substrate |

|

|

|

| Mask material/thickness |

|

|

Pattern defined in the ICP metal |

| Coil Power |

|

|

|

| Platen Power |

|

|

|

| Platen temperature |

|

|

|

| He flow |

|

|

|

| C4F8 flow |

|

|

|

| O2 flow |

|

|

|

| H2 flow |

|

|

|

| Pressure |

|

|

|

| Etch rate in fused silica |

± refers to the variation over the wafer. |

± refers to the variation over the wafer. |

|

| Selectivity to mask |

|

|

|

| Linewidth reduction |

|

|

|

| Substrate size tried |

|

|

|

| Images |

|

|

User results

Done by Joachim Thomsen (student at Nanotech) October 2013

The process flow was:

- Fused silica wafers

- Deposition of poly-Si on the wafers: LPCVD poly-Si furnace, recipe poly620, 1h30m: aprox. thickness 700nm

- Adding AZ resist mask

- Etching the poly-Si mask: AOE recipe "si_etch": 30s

- Etching the fused silica: using AOE recipe "m_polysi": 11min10sec

Results:

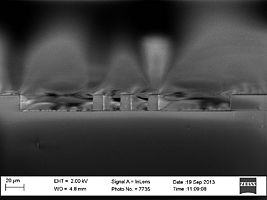

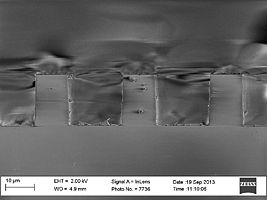

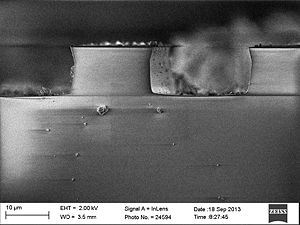

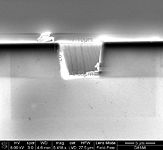

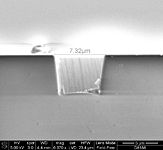

- 5 µm channels in fused silica after AOE etch - the poly-Si mask is still on

-

Profile of 5µm channel

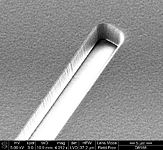

-

5 µm wide channel see from above (tilted)

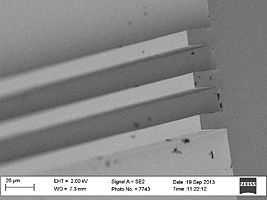

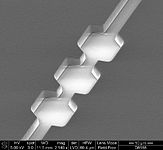

-

channel see from above (tilted)

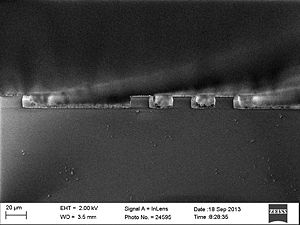

-

Profile of 5 µm channel