Specific Process Knowledge/Characterization/XRD/XRD SmartLab/ALD deposited alumina and titania XRR

Purpose of the work

The work described below was conducted in 2019 by Sarah Elisabeth Hussein El Dib (s135170) and Evgeniy Shkondin, DTU Nanolab as a part of the master project in collaboration with the DTU Photonics Department.

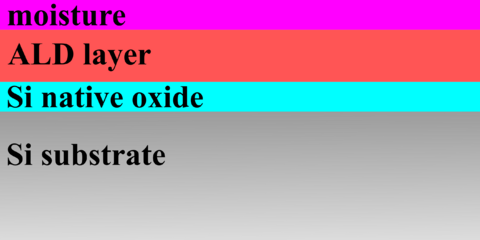

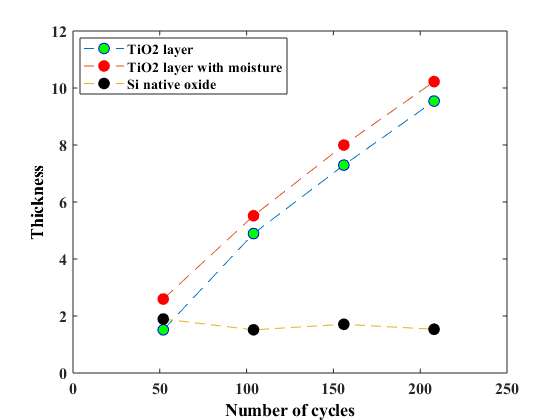

The deposition of ultrathin layers (with thickness below 10 nm) is difficult to characterize with ellipsometry alone, because of the model complexity. The prepared samples consist of a thin ALD film, but in order to properly distinguish it, the native oxide and surface moisture (with adventitious carbon contamination) should be taken into account since whey both have thicknesses comparable to ALD ultra-thin layer. For this purpose, the XRR method was employed.

Deposition characteristics

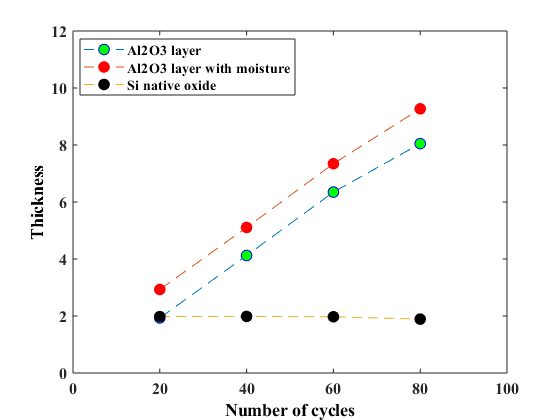

A sequence of samples has been made by deposition Al2O3 and TiO2 on flat natively oxidized Si (100) samples. The thickness setpoints were chosen to be 2, 4, 6, and 8 nm, and a number of cycles calculated from the published growth rates which were verified for thicker films (20-100nm).

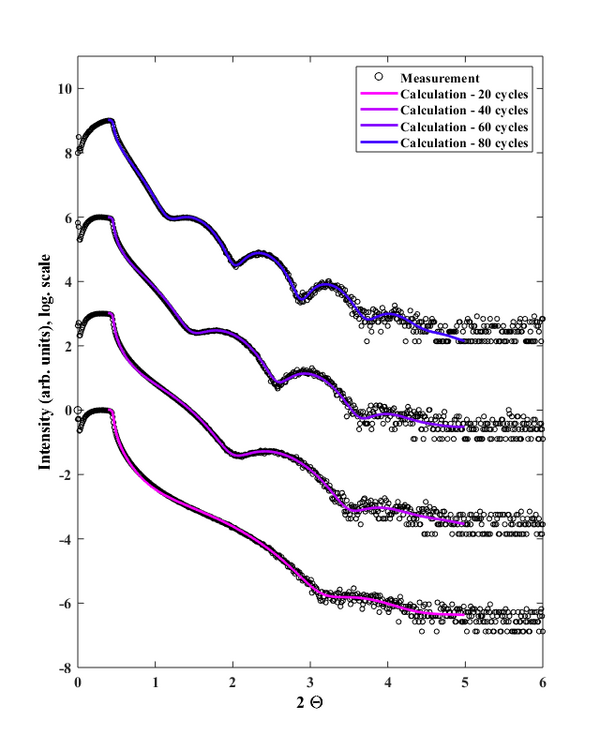

Deposition of Al2O3

The standard recipe for deposition of Al2O3 on flat and high aspect ratio structures has been used.

Equipment: ALD-1

Recipe: AL2O3

Assumed deposition rate: 0.097 nm/cycle

Temperature: 200 oC

| TMA | H2O | |

|---|---|---|

| Nitrogen flow | 150 sccm | 200 sccm |

| Pulse time | 0.1 s | 0.1 s |

| Purge time | 3.0 s | 4.0 s |

Number of cycles: 20, 40, 60, 80 for 2nm, 4nm, 6 nm and 8 nm respectively.

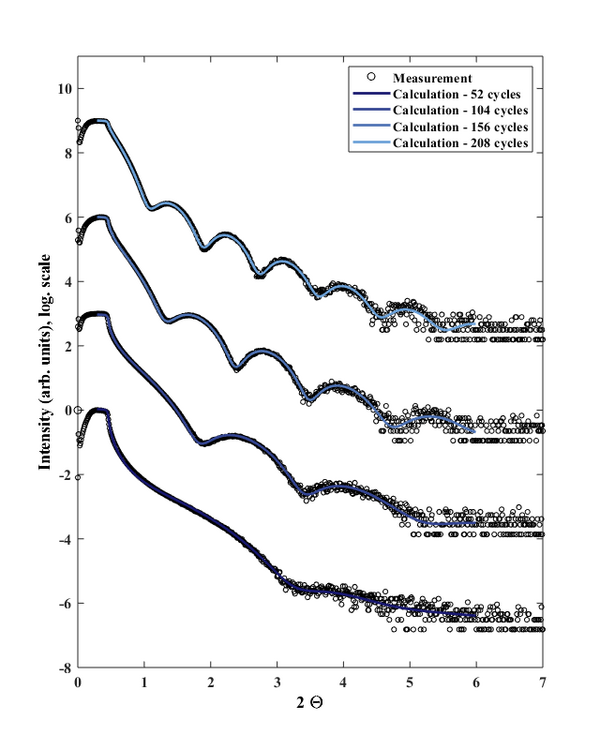

Deposition of TiO2

The standard recipe for deposition of amorphous TiO2 on flat and high aspect ratio structures has been used.

Recipe: amorphous TiO2,

Equipment: ALD-2

Assumed deposition rate: 0.0385 nm/cycle

Temperature: 150 oC

| TiCl4 | H2O | |

|---|---|---|

| Nitrogen flow | 150 sccm | 150 sccm |

| Pulse time | 0.1 s | 0.1 s |

| Purge time | 4.0 s | 6.0 s |

Number of cycles: 52, 104, 156, 208 for 2nm, 4nm, 6 nm and 8 nm respectively.

X-ray reflectivity results

X-ray reflectivity (XRR) profiles for Al2O3 and TiO2 films at different number of cycles has been obtained using Rigaku XRD SmartLab equipment. Fitting procesure was performed using commercial GlobalFit software assuming the model based on Si substrate with native oxide followed by the deposited ALD layer with thin moisture surface. The results are summarized in a tables below.

- Sample model used in XRR analysis.

-

Sample considers to have ALD layer with top moisture deposited on natively oxidized silicon.

Si reference samples

- All XRR scans.

-

Measuring Si reference sample with and without native oxide.

| Physical properties of Si reference sample with and without native oxide | |||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||

Thin films samples

- All XRR scans.

-

All Al2O3 samples scan.

-

All TiO2 samples scan.

bla bla bla

| XRR results for Al2O3 layers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

bla bla bla

| XRR results for TiO2 layers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

blabla bla

- All XRR scans.

-

All Al2O3 samples scan.

-

All TiO2 samples scan.