Specific Process Knowledge/Thin film deposition/DiamondCVD/Diamond CVD process details

Feedback to this page: film deposition/DiamondCVD/Diamond_CVD_process_details click here

THIS PAGE IS UNDER CONSTRUCTION

Diamond growth by MPCVD at Nanolab

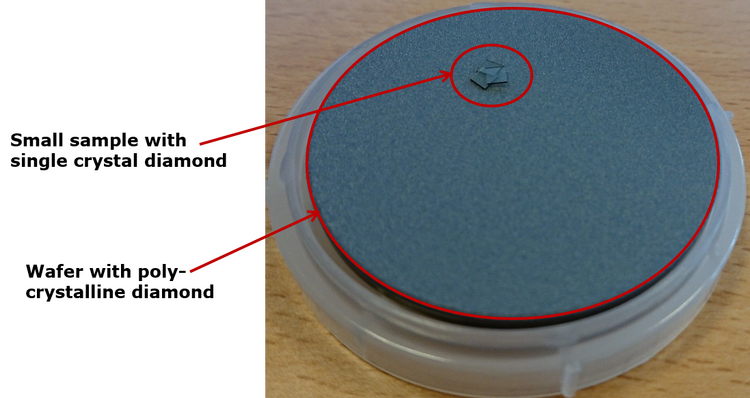

At Nanolab, it is possible to grow single- and polycrystalline diamond in the SEKI diamond CVD.

Single- and polycrystalline diamond

It is possible to grow extremely clean diamond in the SEKI system. It is also possible to control the N2 dopant level and dopant depth. Nitrogen doping affects the optical and electronic properties of the diamond. For instance this can be used in magnetic sensors, which is a topic of research at DTU Physics.

For polycrystalline growth the substrate must be seeded with diamonds as mentioned above. This is commonly done by sonicating the substrate in a solution of water with nano diamonds. After sonication the substrate is rinsed in water and blow-dried.

Polishing is needed after deposition if the polycrystalline diamond layer has to be smooth. Thinning is needed if the diamond layer has to be very thin as a uniform diamond layer can only be deposited above 1 μm thickness.

Diamond formation (a bit of theory)

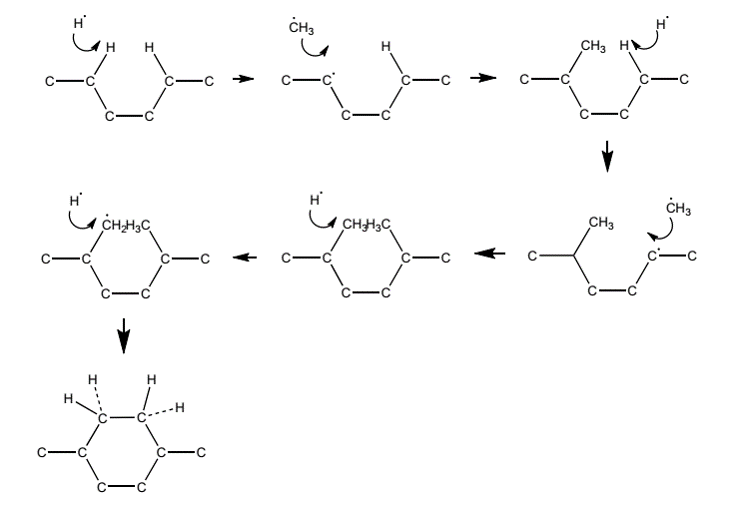

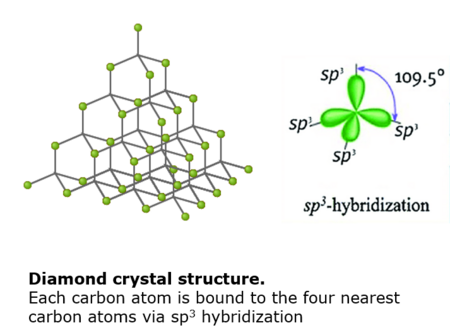

Diamond is grown by depositing carbon from the CH4 on a substrate. If the carbon forms an sp3 bond to other carbon atoms, diamond is grown. Otherwise it will be etched away by a high concentration of H2. Diamond is very inert, but the plasma in the CVD equipment creates hydrogen radicals that in turn create active sites on the diamond surface. These active sites react with methane radicals that are also created in the plasma.