Specific Process Knowledge/Thin film deposition/Deposition of Nickel/Electroplating of nickel

Electroplating of nickel: DTU Nanolab standard processes

Feedback to this page: click here

DTU Nanolab Standard Programs

Three different standard programs have been made by DTU Nanolab. They have all been made to fabricate nickel shims for use in the polymer injection molding machine at DTU Nanolab. For this purpose a nickel thickness of around 340-360 µm is optimal. By experimentation it has been found that the required charge for this sample thickness is 18,3 Ah. The only difference between the different standard programs is the time required for depositing the nickel. The three different standard programs deposit the ~350 µm of nickel in about 4, 6 or 12 hours respectively.

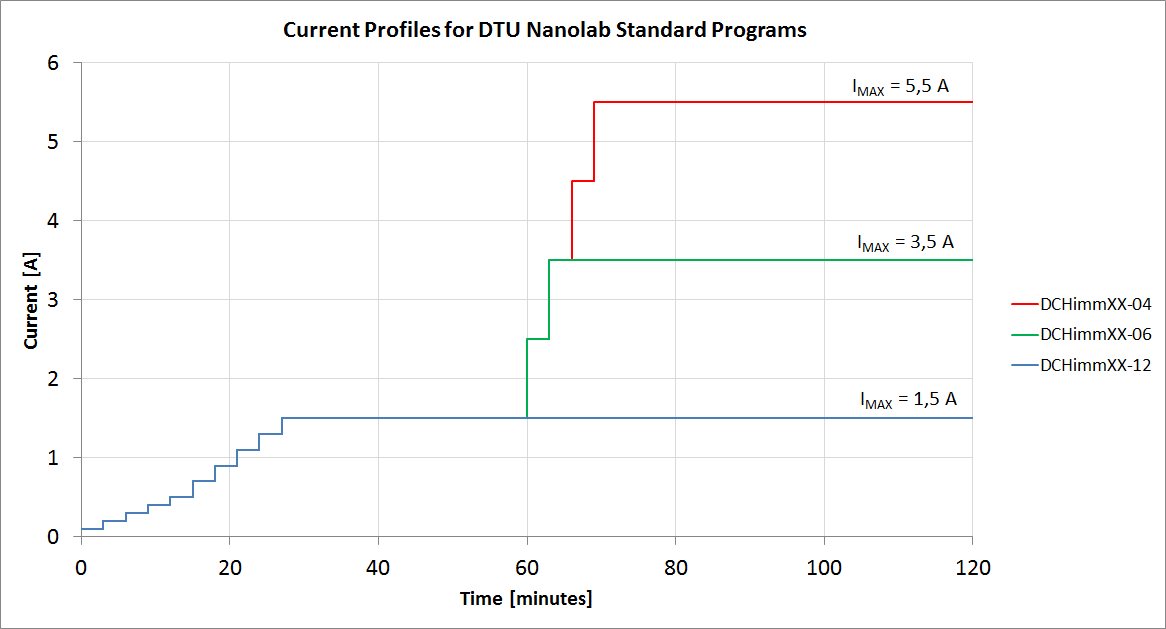

The following figure shows the current profile during the first 2 hours of the programs:

As can be seen from the illustration the first 30 minutes of all standard processes are identical. All processes use a slow ramping of the current. This is to make sure that some material is deposited which can conduct a higher current. Starting a plating process at several amperes is very likely to damage the sample (and possibly the sample holder) because the seed metal layer (usually 50-120 nm thick) cannot support such high currents.

The Standard programs are named using the following convention: DCHimmXX.X-YY where DCH indicates it's a process developed by Nanolab, imm that is a process developed for producing samples for the injection molding machine, XX.X denotes the charge in Ah (Ampere-hours) and YY denotes the approximate process time in hours.

Comparison of standard processes

| DCHimm18.3-04 | DCHimm18.3-06 | DCHimm18.3-12 | |

|---|---|---|---|

| Charge [Ah] | 18,3 | 18,3 | 18,3 |

| Expected nickel thickness | 350 µm | 350 µm | 350 µm |

| Maximum current [A] |

5,5 |

3,5 |

1,5 |

| Process time [hh:mm:ss] |

04:10:55 |

06:12:52 |

12:28:01 |

| Process comments |

A fast program that allows one to produce two samples in a normal working day. Usually works fine for rapid prototyping. |

A compromise between desired material properties (hardness, ductility, roughness) and process time. Will result in a sample that will be useful for most standard injection molding processes. |

A slower process that in return results in lower roughness and stronger mechanical properties. A good choice for shims that will be used with 'harsh' injection molding parameters (high temperatures and high pressures). |