Specific Process Knowledge/Thin film deposition/ALD Picosun R200/HfO2 deposition using ALD

Feedback to this page: click here

The ALD temperature window for HfO2 is 150 - 300 oC.

The TEMAHf precursor is heated to 125 oC (TE210) and the heater (TE211 max.) is set to 140 oC during deposition. Remember to set the values in the "MANUAL" tab and to change them to back after deposition (TE211 max. to 1 oC). These values may not be exceeded to prevent precursor decomposition. Due to the heating of the precursor the stabilization time needs to be set to 60 min. Else an alarm (TE210 PID limit exceeded while pulsing) will be triggered and the process will be stopped after the first pulsing attempt.

HfO2 standard recipe

HfO2 deposition using TEMAHf and H2O precursors

The following tables show the recipe and boost settings for the TEMAHf precursor:

| TEMAHf | H2O | |

|---|---|---|

| Nitrogen flow | 150 sccm | 120 sccm |

| Pulse time | 1.6 s | 0.1 s |

| Purge time | 8.0 s | 4.0 s |

| Boost flow | 500 sccm |

|---|---|

| Pre-empty | 0.5 s |

| Master fill | 1.2 s |

| Post-empty | 0 s |

HfO2 deposition at 150 oC

Two HfO2 depositions were made January 2018 - One for 91 cycles and one for 250 cycles. Both deposition were done on 4" wafers with native oxide. The deposition temperature was 150 oC , and the precursor temperature (T210) for TEMAHf was 125 oC.

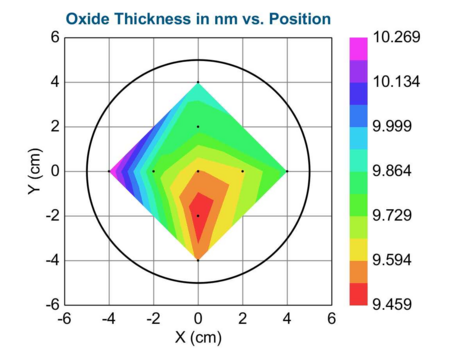

Number of cycles: 91

Results:

Average HfO2 thickness: 9.57 nm (measured in nine points)

Deposition rate: 0.11 nm/cycle

Non-uniformity: 4.15 %

-

Ellipsometer measurement of HfO2. Deposition temperature: 150 oC. Number of cycles: 91.

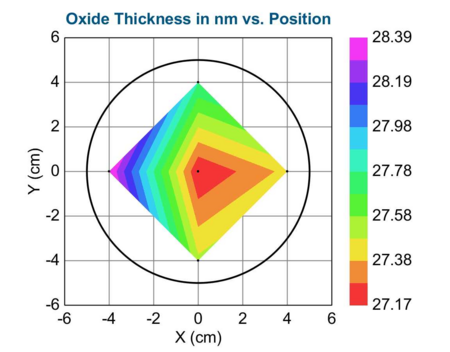

Number of cycles: 250

Results:

Average HfO2 thickness: 27.65 nm (measured in five points)

Deposition rate: 0.11 nm/cycle

Non-uniformity: 2,20 %

-

Ellipsometer measurement of HfO2. Deposition temperature: 150 oC. Number of cycles: 250.

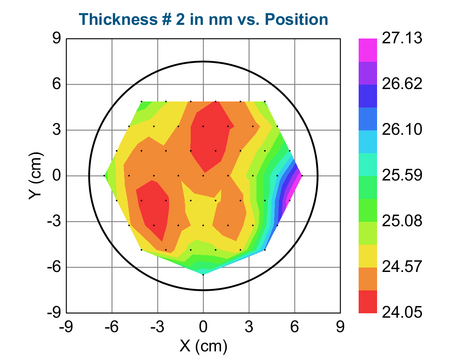

HfO2 deposition at 250 oC

The test was done with 300 cycles at 250 oC where the deposition rate was measured to be 0.0827 nm/cycle. The precursor temperature (T210) for TEMAHf was 125 oC.

-

Ellipsometer measurement of HfO2. Deposition temperature: 250 oC. Number of cycles: 300.

| Parameter | Average | Min. | Max. | Std.Dev | %Range |

|---|---|---|---|---|---|

| Thickness (nm) | 24.83 | 24.05 | 27.13 | 0.68 | 12.38 |

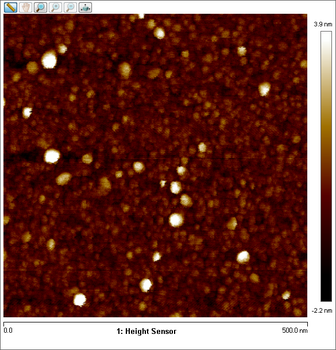

-

AFM measurement roughness 0.3784 nm.

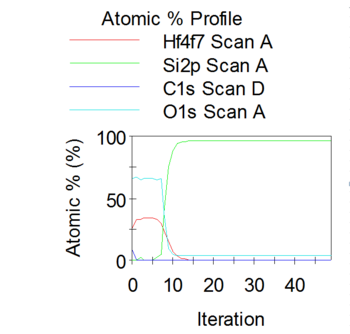

The XPS measurement was made by our XPS-ThermoScientific and shows that the film is purely HfO2 except for some impurities on the surface.

-

Atomic percentage distribution of a depth profile.

Tanja Amport, Pernille Voss Larsen and Mikkel Dysseholm Mar, DTU Danchip, 2017.